A circular saw is a versatile power tool that is commonly used in woodworking, construction, and other related industries. It consists of a round blade with sharp teeth and a motor that rotates the blade at a high speed. The circular saw is designed to cut through various materials, including wood, metal, plastic, and more.

The functionality of a circular saw is relatively straightforward. When the saw is turned on, the motor provides the power to rotate the blade. The blade’s teeth cut into the material being worked on, creating a clean and precise cut. The circular shape of the blade allows for continuous cutting, making it efficient and effective for various cutting tasks.

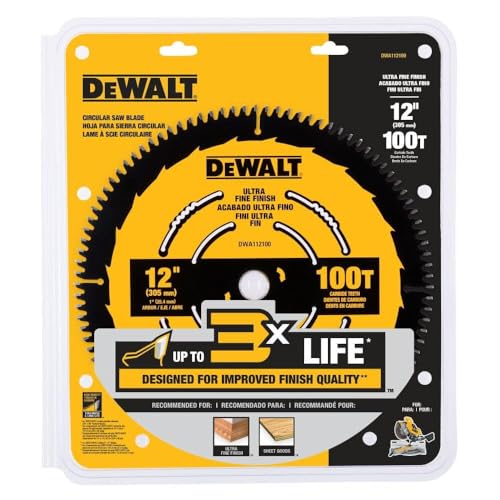

The blade of a circular saw is typically made from a durable material, such as carbide or diamond-tipped, which ensures longevity and sharpness. The sharp teeth on the blade help to cut through the material with ease, minimizing the effort required by the user. Additionally, some circular saws have adjustable blade angles, allowing for bevel cuts at different angles.

Using a circular saw requires proper technique and safety precautions. It is crucial to wear appropriate protective gear, such as safety goggles and gloves, to prevent any accidents or injuries. The user should also ensure that the material being cut is secure and stable, as any movement or vibration can affect the accuracy of the cut.

In conclusion, a circular saw is a powerful and efficient tool that plays a vital role in various industries. Its simple yet effective functionality, along with its versatility, makes it a popular choice among professionals and DIY enthusiasts alike. With proper technique and safety precautions, a circular saw can be a valuable asset for any woodworking or construction project.

Overview of Circular Saw

A circular saw is a versatile power tool commonly used in woodworking and construction projects. It consists of a circular blade with sharp teeth, mounted on an arbor, which spins rapidly to cut through various materials. Circular saws can be handheld or table-mounted, and they are known for their ability to make quick and precise cuts.

Blade and Motor

The blade is the most crucial component of a circular saw. It is typically made of high-strength steel and comes in various sizes and types, such as rip blades for cutting with the grain and crosscut blades for cutting across the grain. The blade is mounted on an electric motor-powered arbor, which generates the spinning motion required for cutting. The motor’s power rating determines the cutting capacity and speed of the saw.

Guard and Shoe

To enhance safety, circular saws are equipped with a retractable blade guard. The guard covers the blade when the saw is not in use and retracts automatically when cutting begins, exposing only a portion of the blade necessary for the cut. The shoe, also known as the base or sole plate, provides stability and acts as a guide for the saw. It is typically made of aluminum or magnesium alloy and features markings and notches to assist with accurate and repeatable cuts.

Circular saws offer adjustable cutting depth and bevel capacity, allowing the user to make cuts at different angles. The cutting depth can be adjusted by raising or lowering the shoe, while the bevel capacity is controlled by rotating the shoe. This versatility makes circular saws suitable for a wide range of applications, from simple crosscuts to intricate miter cuts.

In conclusion, a circular saw is a powerful and versatile tool that can efficiently cut through various materials. By understanding its components and features, users can make precise and accurate cuts for their woodworking and construction projects.

Power Source and Motor

A circular saw is typically powered by electricity, either from a cord connected to a power outlet or from a battery pack. This power source provides the energy needed to run the saw and spin its motor.

The motor of a circular saw is responsible for converting the electrical energy from the power source into mechanical energy that drives the blade. Most circular saws use a motor with a rotating armature, which is the part that spins the blade.

The power of the motor is measured in horsepower (HP) or watts (W). Higher horsepower or wattage generally means more cutting power, allowing the saw to cut through denser materials with ease.

Types of Motors

There are two main types of motors used in circular saws: brushed motors and brushless motors.

Brushed motors have carbon brushes that come into contact with the spinning armature. These brushes deliver electrical current to the armature and help it rotate. Although brushed motors are generally less expensive, they require more maintenance due to the wear and tear of the brushes, which need to be replaced periodically.

In contrast, brushless motors do not have brushes. Instead, they use a series of magnets and electronic circuits to control the flow of electrical current to the motor. Brushless motors are typically more efficient and have a longer lifespan compared to brushed motors. They also provide smoother and quieter operation.

Motor Speed and Control

The speed of the circular saw’s motor is usually measured in revolutions per minute (RPM). Higher RPMs mean that the blade will spin faster, resulting in smoother and quicker cuts.

Many circular saws have variable speed control, which allows the user to adjust the motor speed according to the material being cut. This feature is especially useful when cutting different types of materials that require different cutting speeds.

Blade and Cutting Action

A circular saw is equipped with a sharp, circular blade that is responsible for making cuts through various materials. The blade is typically made of high-speed steel or carbide-tipped teeth, which ensure durability and efficient cutting performance.

When the circular saw is turned on, the motor rotates the blade at a high speed. The spinning motion of the blade creates a cutting action that allows it to slice through the material. As the blade makes contact with the material, the teeth on the edge of the blade penetrate and remove material, creating a cut.

The cutting action of a circular saw is achieved through a combination of factors. The design and shape of the blade teeth play a crucial role in determining the type of cut it can make. Blades with finer teeth are suitable for making smooth cuts on delicate materials, while blades with coarser teeth are more effective at cutting through thicker materials.

The depth of the cut is determined by the distance between the blade and the base plate of the circular saw. By adjusting the depth of cut, users can control how deep the blade penetrates into the material.

It is important to note that different types of blades are available for specific applications. For example, there are blades designed for cutting wood, metal, plastic, and other materials. Using the appropriate blade for the intended material ensures cleaner cuts and prolongs the lifespan of both the blade and the saw.

Blade Maintenance

To ensure optimal cutting performance and longevity of the blade, regular maintenance is necessary. The blade should be kept clean and free from debris that can accumulate during cutting. It is recommended to use a brush or compressed air to remove any residue.

Additionally, blade lubrication can improve cutting efficiency and reduce heat generated during operation. Applying a lubricating spray or wax on the blade helps reduce friction, allowing the blade to cut through the material with ease.

Safety Precautions

When using a circular saw, safety precautions should always be followed. It is important to wear appropriate safety gear, such as safety goggles and gloves, to protect against potential hazards.

Furthermore, it is crucial to ensure that the workpiece is securely clamped or supported to prevent it from moving during cutting. This helps reduce the risk of kickback or the material shifting unexpectedly.

Lastly, users should be mindful of the blade guard and keep it in proper working condition. The blade guard helps protect against accidental contact with the blade and should be functioning correctly at all times.

Safety Features and Precautions

When using a circular saw, it is important to prioritize safety to prevent accidents and injuries. Here are some safety features and precautions to keep in mind:

1. Blade Guard:

Make sure the circular saw you are using has a blade guard. This protective cover helps prevent accidental contact with the blade and reduces the risk of injury. Always check that the blade guard is in good working condition before using the saw.

2. Safety Switch:

Most circular saws are equipped with a safety switch to prevent accidental starting. This switch requires you to press it before activating the saw. Always keep the safety switch engaged when the saw is not in use to avoid any unintended start-ups.

3. Protective Gear:

Wear appropriate protective gear when operating a circular saw. This includes safety glasses to protect your eyes from flying debris, ear protection to reduce noise levels, and gloves to provide a better grip on the saw and protect your hands.

4. Work Area Preparation:

Before using a circular saw, ensure that your work area is clean and well lit. Remove any obstacles or clutter that may interfere with your movements. Also, make sure the material you are cutting is properly secured to prevent it from shifting during operation.

5. Proper Handling:

Hold the circular saw firmly with both hands and maintain a steady grip throughout the cutting process. Avoid reaching over the blade or placing your hands in the path of the saw. Use the appropriate cutting techniques recommended by the manufacturer to ensure safe and efficient operation.

6. Power Source Safety:

When using a corded circular saw, always ensure that the power cord is in good condition and properly grounded. Keep the cord away from the cutting area to avoid accidental contact with the blade. If using a cordless circular saw, make sure the battery is fully charged and securely attached to the tool.

7. Maintenance and Inspection:

Regularly inspect and maintain your circular saw to ensure its safety and optimal performance. Check for any loose or damaged parts, including the blade, guard, and handles. Follow the manufacturer’s guidelines for blade changing and maintenance to avoid accidents.

By following these safety features and precautions, you can minimize the risk of accidents and injuries while using a circular saw. Always prioritize safety and take the necessary precautions to protect yourself and others in the work area.

Applications and Advantages

Applications:

The circular saw has a wide range of applications and is used in various industries and professional settings:

- In carpentry and woodworking, circular saws are essential tools for making accurate and precise cuts in different materials such as wood, plywood, and MDF.

- In construction, circular saws are used for cutting through various building materials like concrete, brick, and metal.

- In metalworking, circular saws with specialized blades are used to cut through different types of metal tubes, pipes, and rods.

- In the automotive industry, circular saws are used for cutting metal parts, including body panels and frames.

Advantages:

The circular saw offers several advantages over other cutting tools:

- Accuracy: Circular saws provide precise and straight cuts, ensuring the desired outcome without any deviations.

- Efficiency: Circular saws are fast and efficient, allowing for quick and precise cutting, which saves time and increases productivity.

- Versatility: Circular saws are versatile tools that can be used for different applications and can cut through various materials.

- Portability: Circular saws are compact and portable, making them easy to transport and use in different locations.

- Adjustability: Circular saws often have adjustable features, such as depth and bevel adjustments, allowing for greater flexibility in cutting different materials and angles.

Overall, the circular saw is a versatile and efficient tool that offers precise cuts and is suitable for a wide range of applications in different industries.