When it comes to cutting steel, there are several factors to consider, and one of the most important ones is the thickness of the steel. A circular saw is a versatile tool that is widely used for cutting different materials, but can it handle cutting steel?

The answer depends on various factors such as the type of circular saw, the blade being used, and the power of the saw. Generally, a circular saw with a high-powered motor and a carbide-tipped blade can cut through steel with ease. However, it is important to note that the thickness of the steel greatly affects the ability of the circular saw to cut through it.

For thinner sheets of steel, up to around 1/8 inch thickness, a circular saw is usually capable of making clean and precise cuts. However, as the thickness of the steel increases, the task becomes more challenging. It may be possible to cut through steel that is up to 1/4 inch thick with a circular saw, but the quality of the cut may suffer, and the saw blade may wear down more quickly.

For thicker steels, such as those over 1/4 inch thick, a circular saw may not be the best tool for the job. In these cases, it is usually recommended to use a more powerful tool such as a reciprocating saw or an angle grinder with a metal-cutting blade. These tools are better equipped to handle the strength and thickness of the steel, ensuring cleaner and more efficient cuts.

What is a circular saw?

A circular saw is a versatile power tool that is commonly used in woodworking and construction. It features a round blade with sharp teeth that rotates rapidly, allowing it to cut through various materials, including wood, plastic, and metal.

The circular saw is handheld and can be powered by electricity or a battery. It is considered a portable tool due to its compact size and lightweight design. The blade is attached to a motor that spins it at high speeds, allowing it to make fast, accurate cuts.

Key Components of a Circular Saw

A circular saw consists of several key components:

- Blade: The circular blade is typically made of high-speed steel or carbide-tipped steel. It comes in various sizes and with different numbers of teeth, allowing it to cut through different materials and achieve different types of cuts.

- Motor: The motor is responsible for powering the blade and determining its cutting speed. Circular saws can have different motor power ratings, which affect their cutting capabilities.

- Base Plate or Shoe: The base plate, also known as the shoe, provides stability and support for the saw while in use. It usually has an adjustable angle and depth settings to allow for different cutting angles and depths.

- Guard: The guard is a safety feature that covers the blade when it is not in use, preventing accidental contact and injuries.

- Handle: The handle provides a comfortable grip and control over the saw during operation.

Uses of a Circular Saw

A circular saw is a versatile tool that can be used for a wide range of cutting tasks. Some common uses include:

- Crosscutting: Cutting wood or other materials across the grain.

- Ripping: Cutting wood or other materials parallel to the grain.

- Miter Cutting: Cutting wood or other materials at an angle, typically for joining pieces at corners.

- Bevel Cutting: Cutting wood or other materials at an angle other than 90 degrees.

- Plunge Cutting: Making cuts starting from the middle of a material, rather than from the edge.

- Dado Cutting: Creating a groove or slot in a piece of wood to accommodate another piece.

Advantages of using a circular saw

When it comes to cutting steel, a circular saw offers several advantages over other cutting tools. Here are some of the main benefits of using a circular saw:

1. Versatility: Circular saws are incredibly versatile tools that can be used to cut a variety of materials, including steel. This makes them a practical choice for both professional contractors and DIY enthusiasts.

2. Precision: Circular saws are designed to provide precise cuts, allowing you to achieve clean and accurate results. This is particularly important when working with steel, as precision cutting is crucial for maintaining the structural integrity of the material.

3. Speed: Circular saws are known for their fast cutting speed. They can quickly and efficiently cut through steel, saving you time and effort compared to other cutting methods.

4. Portability: Circular saws are generally lightweight and easy to transport, making them ideal for projects that require mobility. Whether you’re working on a construction site or in a workshop, a portable circular saw allows you to move around with ease.

5. Adjustable depth and angle: Circular saws often come with adjustable depth and angle settings, allowing you to customize your cuts based on the specific requirements of your project. This flexibility is especially useful when cutting different thicknesses of steel.

6. Affordable: Circular saws are relatively affordable compared to other cutting tools, making them a cost-effective choice for cutting steel. They offer a good balance of price and performance, making them a popular option for both professionals and DIYers.

Overall, a circular saw is a versatile, precise, fast, portable, adjustable, and cost-effective tool for cutting steel. Whether you’re cutting thin sheets or thick plates, a circular saw can provide you with the convenience and efficiency you need to tackle your steel cutting projects.

Maximum Thickness for Steel Cutting

When using a circular saw for steel cutting, it is important to consider the maximum thickness that can be cut efficiently and safely. While circular saws are versatile tools, they do have limitations when it comes to cutting through steel.

The maximum thickness of steel that can be cut with a circular saw depends on several factors, including the power of the saw and the type of blade being used. Generally, most circular saws are capable of cutting through steel up to 1/8 inch thick. However, some more powerful models may be able to handle steel up to 1/4 inch thick.

It is important to note that attempting to cut steel that is thicker than the saw’s capabilities can result in damage to the tool, as well as a lack of precision and safety concerns. Therefore, it is advisable to use alternative cutting methods, such as a plasma cutter or a metal cutting bandsaw, for thicker steel materials.

When using a circular saw for steel cutting, it is crucial to use the correct blade for the task. Blades specifically designed for cutting through steel are available and should be used to ensure clean and efficient cuts. It is also recommended to wear appropriate safety gear, including safety glasses and gloves, when working with a circular saw.

In conclusion, while circular saws can be used for cutting steel, their maximum thickness capabilities are limited. It is important to consider the power of the saw and use the appropriate blade for the task. For thicker steel materials, alternative cutting methods should be utilized to ensure safety and precision in the cutting process.

What factors affect the maximum thickness?

When determining the maximum thickness of steel that can be cut with a circular saw, several factors must be taken into consideration. These factors include:

1. Blade Diameter:

The diameter of the circular saw blade plays a significant role in determining the maximum thickness of steel that can be cut. Typically, larger blades have a greater cutting capacity and can cut through thicker materials. For example, a 7 ¼ inch circular saw blade can generally cut through steel up to ⅜ inch thick, while a 10-inch blade may be able to cut through steel up to ½ inch thick.

2. Blade Type:

The type of blade used in the circular saw also affects the maximum thickness of steel that can be cut. There are different blade types available, such as abrasive blades, carbide-tipped blades, and diamond blades. These blades are specifically designed for cutting through different materials, including steel. Carbide-tipped blades and diamond blades are generally more effective in cutting thicker steel compared to abrasive blades.

3. Motor Power:

The power of the circular saw’s motor plays a crucial role in its cutting capacity. More powerful motors are capable of generating higher rotational speed and torque, allowing them to cut through thicker and tougher materials. A circular saw with a higher motor power rating will typically have a greater maximum cutting depth for steel.

4. Cutting Speed:

The cutting speed at which the circular saw is operated also affects the maximum thickness of steel that can be cut. Cutting speed refers to the rate at which the saw blade moves through the material being cut. Slower cutting speeds may be required for cutting thicker steel, as higher speeds can result in increased heat and friction, which can lead to blade dulling and reduced cutting efficiency.

5. Material Hardness:

The hardness of the steel being cut is an important factor to consider. Harder steels may require more powerful circular saws, specialized blades, or slower cutting speeds to achieve clean and efficient cuts. Softer steels may be easier to cut through, allowing for a greater maximum thickness that can be cut.

In summary, the maximum thickness of steel that can be cut with a circular saw is determined by factors such as the blade diameter, blade type, motor power, cutting speed, and material hardness. These factors should be carefully considered when selecting the appropriate circular saw and blade for the desired cutting application.

| Factor | Impact on Maximum Thickness |

|---|---|

| Blade Diameter | Larger diameter blades generally have a greater cutting capacity. |

| Blade Type | Carbide-tipped and diamond blades are more effective for cutting thicker steel. |

| Motor Power | More powerful motors allow for cutting through thicker and tougher materials. |

| Cutting Speed | Slower cutting speeds may be required for cutting thicker steel. |

| Material Hardness | Harder steels may require specialized equipment or slower cutting speeds. |

Recommended thickness for cutting with a circular saw

A circular saw is a versatile power tool that can be used for cutting various materials, including steel. However, the cutting capacity of a circular saw can vary depending on its specifications and the type of blade used. When it comes to cutting steel with a circular saw, it is important to consider the thickness of the material to ensure both the effectiveness of the saw and your safety.

In general, a circular saw can efficiently cut through steel sheets that have a thickness of up to 1/8 inch. This thickness is commonly found in lightweight steel materials and is within the cutting capacity of most circular saws.

If you need to cut thicker steel sheets, it is recommended to use a specialized blade with a higher tooth count and increased cutting capacity. These blades typically have thicker carbide tips and are designed specifically for cutting through thicker steel materials.

It is important to note that when cutting thicker steel materials, the cutting process may become slower and more challenging. Therefore, it is crucial to use appropriate safety precautions, such as wearing protective gear and securely clamping the material to prevent any movement during the cutting process.

Overall, while a circular saw can be used for cutting steel, it is best suited for thinner steel materials up to 1/8 inch in thickness. For cutting thicker steel, it is advisable to use specialized blades and take extra safety measures to ensure optimal results and personal safety.

Choosing the Right Circular Saw Blade

When it comes to cutting steel with a circular saw, selecting the correct blade can make a significant difference in the quality of your cuts. There are several factors to consider when choosing the right circular saw blade for cutting steel, including the blade diameter, tooth count, and material compatibility.

The first thing to consider is the blade diameter. Circular saw blades come in various sizes, and the recommended blade diameter for cutting steel typically ranges from 7 1/4 inches to 12 inches. A larger blade diameter allows for deeper cuts, but it may also require a more powerful saw.

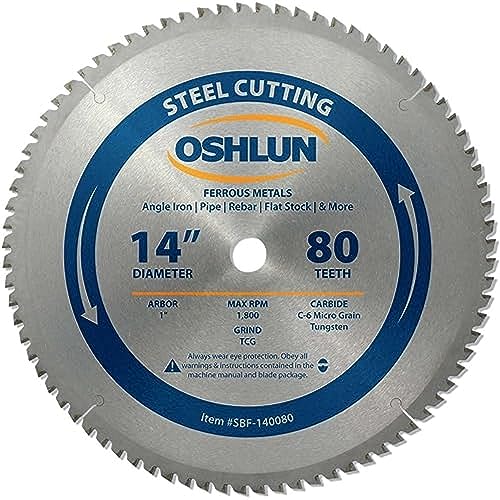

The next consideration is the tooth count. The tooth count refers to the number of teeth on the blade. For cutting steel, a blade with a higher tooth count is generally preferred as it produces smoother cuts. A blade with a tooth count of 60 or higher is recommended for cutting steel.

Material compatibility is another important factor to consider when selecting a circular saw blade. Not all blades are designed to cut through steel, so it is crucial to choose a blade specifically designed for metal cutting. Look for blades that are labeled for cutting steel or metal to ensure the best results.

| Blade Diameter | Tooth Count | Material Compatibility |

|---|---|---|

| 7 1/4 inches | 60 or higher | Metal cutting blade required |

| 8 inches | 60 or higher | Metal cutting blade required |

| 10 inches | 60 or higher | Metal cutting blade required |

| 12 inches | 60 or higher | Metal cutting blade required |

It is important to note that the thickness of steel that can be cut with a circular saw also depends on the power and speed of the saw. While a circular saw can cut through thin steel sheets, thicker steel may require a more powerful saw or a specialized cutting tool.

By considering the blade diameter, tooth count, and material compatibility, you can choose the right circular saw blade for cutting steel and achieve clean and precise cuts.

Blade types for cutting steel with a circular saw

When it comes to cutting steel with a circular saw, choosing the right blade is crucial for achieving clean and efficient cuts. There are several blade types available that are specifically designed for cutting through steel. Let’s take a look at some of the commonly used blade types for this purpose:

1. Abrasive blades:

Abrasive blades, also known as cutting discs or cutoff wheels, are suitable for cutting thin steel materials. These blades are made of abrasive grains bonded together by a resin. They are highly effective in cutting through steel due to their hardness and fast cutting speed. However, they tend to wear out quickly and produce a lot of sparks and heat during the cutting process.

2. Metal cutting blades:

Metal cutting blades, also known as cold cut blades or TCT (tungsten carbide tipped) blades, are specifically designed for cutting steel. These blades have teeth with hardened tips that can withstand the hardness of steel. They are more durable than abrasive blades and provide cleaner cuts with minimal sparks and heat. Metal cutting blades are available in various sizes and tooth configurations to suit different cutting requirements.

3. Diamond blades:

Diamond blades are the ideal choice for cutting steel with a circular saw when precision and smooth cuts are required. These blades have diamond grit embedded in their cutting edge, which makes them extremely strong and resistant to wear. Diamond blades can easily cut through steel plates, pipes, and other thick steel materials. However, they are more expensive than other blade types and require proper cooling during the cutting process to prevent overheating.

When selecting a blade for cutting steel with a circular saw, it is important to consider the thickness of the steel material, the desired cut quality, and the frequency of use. It is always recommended to follow the manufacturer’s guidelines and use appropriate safety measures when working with a circular saw.

Factors to consider when selecting a blade

When it comes to cutting steel with a circular saw, selecting the right blade is essential. The blade you choose can greatly impact the efficiency and effectiveness of your cutting process. Here are some factors to consider when selecting a blade for cutting steel:

1. Material: Different blades are designed to cut through specific materials. When cutting steel, you need a blade that is specifically designed for metal cutting. These blades are usually made from high-speed steel (HSS) or carbide, which have the durability and hardness required to cut through steel.

2. Blade thickness: The thickness of the blade is an important factor to consider. Thicker blades are generally more durable and can handle heavier cutting tasks. However, they may also produce more heat and require more power to operate. Thinner blades, on the other hand, can provide faster cutting speed and are generally easier to handle. Consider the thickness of the steel you are cutting and choose a blade that can handle it.

3. Tooth count: The tooth count refers to the number of teeth on the blade. A higher tooth count generally results in a smoother cut, but it may also reduce cutting speed. For cutting steel, blades with a lower tooth count are usually recommended as they can withstand the hardness of the material and provide faster cutting speed.

4. Blade diameter: The blade diameter will determine the maximum cutting depth of your circular saw. Make sure to choose a blade with a diameter that is suitable for the thickness of the steel you want to cut. It’s important to note that using a blade with a diameter that is too small may cause the blade to bind or overheat, while a blade with a diameter that is too large may not provide adequate cutting efficiency.

5. Blade quality: Lastly, consider the quality of the blade. Investing in a high-quality blade will ensure longevity and better cutting performance. Look for blades that are made from high-quality materials and have undergone proper heat treatment and sharpening processes.

By considering these factors, you can select the right blade for cutting steel with a circular saw, ensuring a smooth and efficient cutting process.