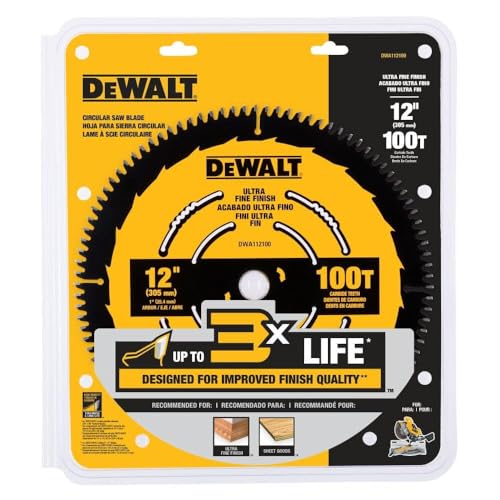

When it comes to making straight cuts with a circular saw, accuracy is key. One small mistake can ruin your project and waste your valuable time and materials. That’s where a circular saw jig comes in handy. With a few simple steps, you can create a jig that will guide your saw and ensure perfectly straight cuts every time.

A circular saw jig is a tool that helps you make straight cuts by providing a guide for your saw. It consists of a base, a fence, and a guide rail. The base is a sturdy platform that supports your workpiece, while the fence and guide rail keep your saw on track.

To make a circular saw jig, start by choosing a suitable base material, such as plywood or MDF. Cut it to the desired size and shape, ensuring that it’s large enough to support your workpiece. Next, attach a straight edge or fence to one side of the base using screws or clamps. This will serve as a guide for your saw. Finally, attach a guide rail to the other side of the base, parallel to the fence, to keep your saw on track.

Once you have constructed your circular saw jig, it’s time to put it to use. Place your workpiece on the base, aligning it with the fence and guide rail. Hold the jig firmly in place with one hand, and with the other hand, start your saw and guide it along the fence. The guide rail will keep your saw on a straight path, ensuring a precise and accurate cut.

Using a circular saw jig is not only convenient, but it also saves you time and effort. No more worrying about keeping your saw straight or making uneven cuts. With a jig, you can achieve professional-looking results with ease. So, the next time you have a project that requires straight cuts, don’t forget to reach for your circular saw jig!

What is a Circular Saw Jig and Why is it Useful?

A circular saw jig is a tool or guide that helps to ensure accurate and straight cuts when using a circular saw. It is a device that you attach to your circular saw, providing a stable and controlled cutting platform. This jig allows you to make straight and precise cuts, eliminating the need for measuring and marking every time.

One of the main advantages of using a circular saw jig is that it helps to save time and effort by providing consistent and accurate cuts. The jig acts as a guide for the saw, enabling you to maintain a straight line while cutting through various materials such as wood, plastic, or metal. This is especially useful when making repeated cuts or when working on projects that require precise dimensions.

Another benefit of using a circular saw jig is that it enhances safety during cutting operations. The jig securely holds the saw in place, reducing the risk of accidental slips or movement that could lead to injuries. It also minimizes the chance of the saw blade wandering, resulting in cleaner cuts and preventing kickbacks.

A circular saw jig can also improve the overall quality of your projects. By ensuring straight and accurate cuts, it helps to achieve professional-looking results. Whether you are working on a DIY project or a professional woodworking assignment, using a jig can enhance the precision and aesthetics of your finished product.

Types of Circular Saw Jigs:

There are several types of circular saw jigs available, each designed for specific cutting applications or materials. Some common types include:

| Type | Description |

|---|---|

| Straight-edge guide | A guide that attaches to the base of the circular saw to ensure straight cuts along a defined edge. |

| Depth guide | A guide that helps to control the depth of the circular saw’s cut, allowing for consistent and accurate cuts. |

| Rip fence | A guide that runs parallel to the saw blade, ensuring straight and parallel cuts when ripping boards or sheets of material. |

| Miter gauge | A guide that helps to make angled or bevel cuts by securely holding the material at the desired angle. |

Conclusion

A circular saw jig is a valuable tool that can greatly improve the accuracy and efficiency of your cutting tasks. It provides a stable and controlled cutting platform, ensuring straight and precise cuts for various materials. By using a circular saw jig, you can save time, enhance safety, and achieve professional-quality results in your woodworking or DIY projects.

How to Build a Straight Edge Circular Saw Jig

If you want to make precise and straight cuts with your circular saw, a straight edge circular saw jig is a must-have tool. This jig helps guide your saw along a straight line, ensuring accurate and professional-looking cuts. Building a circular saw jig is a straightforward process that can be done with just a few tools and materials.

Materials Needed:

- A piece of plywood – 1/2 inch thick and longer than your saw’s base plate

- A straight piece of wood – at least 1 inch thick and longer than your plywood

- Wood screws

- A circular saw

- A drill

- A saw

- Sandpaper

Step-by-Step Guide:

- Start by cutting the plywood to the desired length for your jig. Make sure it is wide enough to accommodate your circular saw’s base plate.

- Next, take the straight piece of wood and align it along one edge of the plywood. This will serve as your guiding rail. Ensure that it is straight and aligned properly.

- Using a drill, pre-drill holes through the wood for the screws. This will prevent the wood from splitting when you attach them together.

- Attach the straight piece of wood to the plywood using wood screws. Make sure it is securely fastened and aligned with the edge of the plywood.

- After securing the two pieces together, place your circular saw on the plywood with the blade against the guiding rail. Ensure that the saw’s base plate is flush against the plywood.

- Mark the position of your saw’s base plate on the plywood. This will serve as a guide for future cuts.

- Remove the circular saw from the jig and use a saw to cut along the marked line. This will create a groove for your saw to sit in.

- Sand the edges of the jig to ensure a smooth and precise cutting surface.

Your straight edge circular saw jig is now ready to use! To make straight cuts, simply align the guiding rail with the desired cut line and run your circular saw along the jig. The straight edge will ensure a precise and accurate cut every time.

Remember to always wear appropriate safety gear and follow proper safety precautions when using power tools.

Choosing the Right Materials for Your Jig

When creating a circular saw jig, it is important to choose the right materials to ensure your jig is sturdy and accurate. Here are some factors to consider when selecting materials for your jig:

1. Plywood: Plywood is a popular choice for making jigs due to its durability and affordability. Look for plywood that is at least 1/2 inch thick to provide enough stability for your jig.

2. MDF: Medium Density Fiberboard (MDF) is another option for building jigs. It is a dense and smooth material that provides a flat surface for your circular saw. MDF is less prone to warping and splintering compared to plywood.

3. Hardwood: Hardwood such as oak or maple can also be used for building jigs. Hardwood is known for its strength and stability, making it a suitable choice for jigs that will be used frequently.

4. Screws and Nails: When assembling your jig, it is important to use screws or nails that are appropriate for the materials you are using. Make sure they are long enough to provide a secure connection without going through the other side.

5. Measuring and Marking Tools: In addition to materials, you will also need measuring and marking tools such as a tape measure, pencil, and square to accurately align and mark your jig components.

Remember to choose materials that are compatible with the size and weight of your circular saw. By selecting the right materials for your jig, you can ensure it is reliable and durable, allowing you to make precise and straight cuts with your circular saw.

Tips for Using a Circular Saw Jig Safely

When using a circular saw jig, it is important to follow certain safety guidelines to prevent injuries and ensure accurate cuts. Here are some tips to help you use a circular saw jig safely:

-

Wear Protective Gear

Always wear appropriate protective gear when using a circular saw jig. This includes safety goggles, ear protection, and gloves. Safety goggles will protect your eyes from flying debris, ear protection will shield your ears from the loud noise, and gloves will provide a better grip and protect your hands from potential injuries.

-

Secure Your Workpiece

Ensure that your workpiece is securely clamped or held in place to prevent it from moving during the cutting process. This will help minimize the risk of accidents and ensure accurate cuts.

-

Position the Circular Saw Correctly

Make sure the circular saw is positioned properly in the jig before making any cuts. The blade should be aligned with the cutting line, and the saw should be firmly held in place to avoid any wobbling or shifting during the cutting process.

-

Check the Blade and Adjust Depth

Before using the circular saw jig, check the condition of the blade. A dull or damaged blade can cause splintering and inaccurate cuts. Additionally, adjust the depth of the blade so that it protrudes slightly below the workpiece. This will help prevent kickback and ensure a smooth and clean cut.

-

Use a Guide Fence

When using a circular saw jig, it is advisable to use a guide fence to ensure straight and accurate cuts. A guide fence can be attached to the jig to guide the saw along the cutting line and prevent any deviations.

-

Take Your Time and Maintain Control

Take your time when making cuts and maintain full control over the circular saw and jig. Rushing can lead to mistakes and accidents. Stay focused and use steady, controlled movements to ensure precise and safe cuts.

-

Disconnect the Power

When not in use or when making adjustments to the circular saw jig, always disconnect the power source to prevent accidental start-ups. This will minimize the risk of injuries and allow for safer handling of the jig.

By following these safety tips, you can use a circular saw jig with confidence, knowing that you are taking the necessary precautions to protect yourself and achieve accurate cuts.

Other Applications of Circular Saw Jigs

A circular saw jig can be a versatile tool that has applications beyond just cutting straight edges. With a few adjustments and modifications, you can use the jig for a variety of tasks. Here are a few other applications of circular saw jigs:

1. Bevel Cuts

By adjusting the angle of the circular saw blade and the position of the jig, you can easily make bevel cuts. This is especially useful when working on projects that require angled edges, such as picture frames or furniture.

2. Angled Cuts

In addition to bevel cuts, circular saw jigs can also be used to make angled cuts. By tilting the jig at a specific angle and guiding the saw along the jig, you can create precise and consistent angled cuts.

3. Curved Cuts

With the right setup, circular saw jigs can also be used to make curved cuts. By attaching a pivot point to the jig and rotating it while guiding the saw along the jig, you can create smooth and accurate curved cuts.

4. Dado Cuts

A circular saw jig can also be used to make dado cuts, which are wide and flat-bottomed grooves often used in woodworking. By adjusting the position of the jig and making multiple passes with the saw, you can create clean and precise dado cuts.

5. Rabbet Cuts

Similar to dado cuts, circular saw jigs can also be used to make rabbet cuts, which are grooves cut at the edge or end of a piece of wood. By adjusting the position and depth of the saw, you can create rabbet cuts of different sizes and depths.

When using circular saw jigs for these applications, it’s important to take proper safety precautions and use the appropriate blades and settings for the specific task. Always wear safety goggles and make sure the wood is securely clamped or held in place before making any cuts. With practice and precision, you can use a circular saw jig to tackle a wide range of cutting tasks with ease.