When it comes to choosing a cut-off saw, size matters. The size of a cut-off saw will impact its functionality and the types of materials it can work with. Whether you are a professional contractor or a casual DIY enthusiast, selecting the right size of cut-off saw is crucial for achieving accurate and efficient results.

A cut-off saw, also known as a concrete saw or a demolition saw, is a powerful tool designed for cutting through hard materials such as concrete, asphalt, and metal. It features a circular blade with serrated teeth that spins at a high speed, allowing it to make precise and clean cuts. The size of the saw refers to the diameter of the blade, which can range from as small as 12 inches to as large as 20 inches or more.

So, how do you determine the appropriate size of cut-off saw for your needs? The answer lies in the type of materials you will be working with and the depth of the cuts you need to make. For smaller jobs that involve cutting through thin materials or making shallow cuts, a smaller cut-off saw with a blade diameter of 12 to 14 inches would suffice. However, if you are tackling larger projects or cutting through thicker materials, a bigger cut-off saw with a blade diameter of 16 to 20 inches would be more suitable.

It’s important to note that bigger doesn’t always mean better when it comes to cut-off saws. While larger saws can handle tougher materials and make deeper cuts, they are also heavier and more difficult to maneuver. They require more strength and may not be suitable for everyone, especially if you are working in tight or confined spaces. Therefore, it’s essential to consider the size and weight of the saw in relation to your own physical abilities and the demands of the job at hand.

In conclusion, choosing the right size of cut-off saw is crucial for achieving optimal results in your cutting projects. Consider the type and thickness of the materials you will be working with, as well as your own physical abilities and the demands of the job. By selecting the appropriate size, you can ensure accurate and efficient cuts, making your cutting tasks safer and more enjoyable.

Choosing the Right Size Cut Off Saw for Your Needs

When it comes to selecting a cut off saw, the size of the saw is an important consideration. The size of the saw can affect its performance and efficiency, as well as determine what types of cutting tasks it is suitable for. Here are a few factors to consider when choosing the right size cut off saw for your needs:

1. Cutting Capacity:

One of the key factors to consider when choosing a cut off saw is its cutting capacity. This refers to the maximum depth and width of the material that the saw can cut through. For smaller cutting tasks, such as cutting through small pieces of wood or metal, a smaller saw with a lower cutting capacity may be sufficient. However, for larger cutting tasks, such as cutting through thick concrete or masonry, a larger saw with a higher cutting capacity will be required.

2. Portability:

An important consideration for many users is the portability of the cut off saw. Smaller saws are generally more portable and easier to transport from one job site to another. They are also easier to maneuver in tight spaces. On the other hand, larger saws may offer more power and cutting capacity, but they can be heavier and bulkier, which may make them less portable and more difficult to handle.

3. Power Source:

Cut off saws can be powered by electricity, gasoline, or battery. The size of the saw may determine the power source options that are available. Smaller saws are typically electric or battery-powered, while larger saws are often gasoline-powered. Consider the availability and convenience of the power source options when choosing the right size cut off saw for your needs.

Overall, it is important to carefully consider your specific cutting needs and requirements when choosing the right size cut off saw. By considering factors such as cutting capacity, portability, and power source, you can ensure that you select a saw that is capable of handling your tasks efficiently and effectively.

Understanding the Different Sizes Available

When it comes to cut off saws, there are various sizes available to meet different needs and applications. These sizes are determined by the diameter of the cutting wheel, which can range from 12 inches to 24 inches or more.

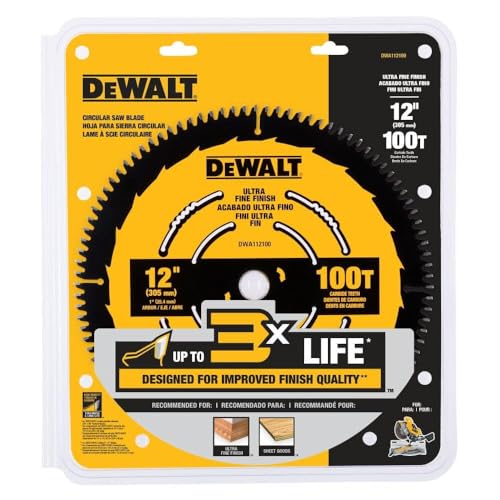

The size of the cut off saw you choose depends on the type of materials you will be cutting and the depth of the cuts you need to make. Smaller cut off saws with a 12-inch cutting wheel are ideal for lighter-duty tasks and are commonly used for cutting metal pipes, rebar, and smaller pieces of stone or concrete.

For heavier-duty applications, such as cutting through thick concrete slabs or large metal beams, a larger cut off saw with a 14-inch to 24-inch cutting wheel is recommended. These larger saws have more power and cutting depth, allowing you to make deeper cuts and tackle tougher materials with ease.

When selecting a cut off saw size, it’s important to consider the size and weight of the saw itself. Larger saws are generally heavier and may require more strength and control to operate. Additionally, larger cut off saws may require a larger space or a dedicated workstation for operation.

Overall, understanding the different sizes available for cut off saws is crucial when determining which saw is best suited for your specific needs. Consider the materials and tasks you will be working with, as well as your own capabilities and workspace limitations.

Factors to Consider When Selecting a Cut Off Saw

When it comes to selecting a cut off saw, there are several important factors to consider. Taking these factors into account can help you choose the right saw for your specific needs and ensure that you get the best results possible.

1. Power source: One of the first things to consider is the power source for your cut off saw. There are several options available, including electric, gas-powered, and hydraulic. Each power source has its own pros and cons, so it’s important to choose one that is most suitable for your situation. Electric saws are generally more convenient and easier to use, while gas-powered saws offer more portability and are often more powerful.

2. Blade size: The blade size of a cut off saw is another important factor to consider. The size of the blade will determine the depth of cut that the saw is capable of making. Depending on your specific needs, you may need a larger blade size for cutting through thicker materials.

3. Cutting capacity: The cutting capacity of a cut off saw refers to the maximum size of material that it can effectively cut. It’s important to choose a saw with the appropriate cutting capacity for the type and size of material you will be working with. Make sure to also consider the angle of the cut, as some saws have limited capacity for making angled cuts.

4. Safety features: Safety should always be a top priority when selecting a cut off saw. Look for saws that have safety features such as blade guards and automatic shut-off mechanisms. These features can help protect you from accidents and injury.

5. Ease of use: Consider how easy the cut off saw is to use before making your decision. Look for features such as ergonomic handles and adjustable cutting depth settings that make the saw more comfortable and convenient to operate.

6. Brand reputation and warranty: Take the time to research the reputation of different brands and read customer reviews before making your final decision. Choosing a reputable brand with a good warranty can help ensure that you are getting a high-quality cut off saw that will last.

By considering these important factors, you can confidently choose a cut off saw that meets your specific needs and provides reliable performance. Whether you need a saw for professional construction work or for DIY projects at home, selecting the right saw can make a significant difference in the quality and efficiency of your work.

Benefits of Using a Large Cut Off Saw

A large cut off saw, also known as a cutoff machine or a chop saw, is a powerful tool that is designed to quickly and accurately cut through various materials including metal, wood, and concrete. There are several benefits to using a large cut off saw that make it an essential tool for many industries and applications.

- Efficiency: One of the main advantages of using a large cut off saw is its efficiency. With its powerful motor and large cutting blade, it can cut through materials with ease, saving both time and effort. This makes it ideal for tasks that require frequent and intense cutting.

- Precision: Another benefit of using a large cut off saw is its ability to provide precise and accurate cuts. The large cutting blade allows for straight cuts, while the adjustable cutting angle and depth ensure that you can achieve the desired cut every time.

- Versatility: Large cut off saws are versatile tools that can be used for a wide range of applications. Whether you need to cut metal pipes, wooden beams, or concrete slabs, a large cut off saw can handle the task efficiently.

- Safety: While using a large cut off saw requires proper training and safety precautions, it can actually be a safer option compared to other cutting tools. The blade guard and safety features help to minimize the risk of accidents and injuries, making it a reliable choice for professionals.

- Durability: Large cut off saws are typically built to withstand heavy-duty use. They are designed with robust materials and components that can withstand the rigors of demanding jobsites. This durability ensures that the tool will last for years and provide consistent performance.

In conclusion, a large cut off saw offers numerous benefits, including efficiency, precision, versatility, safety, and durability. Whether you are a professional contractor, a DIY enthusiast, or someone who frequently works with various materials, investing in a large cut off saw can greatly enhance your cutting capabilities and productivity.

Benefits of Using a Small Cut Off Saw

When it comes to cutting materials, having the right tools can make all the difference. One tool that proves to be incredibly useful in various industries is a small cut off saw. While larger cut off saws have their own advantages, there are several benefits to using a small cut off saw that should not be overlooked.

1. Portability and Ease of Use

A small cut off saw is typically more portable and easier to handle compared to larger saws. Their compact size and lightweight design allow for easy transportation and maneuverability. Whether you are working in a tight space or need to move the saw from one job site to another, a small cut off saw provides the convenience you need.

2. Versatility

Despite their smaller size, small cut off saws are still capable of cutting through a wide range of materials. From wood and metal to concrete and tiles, these saws can handle different materials with ease. This versatility makes them suitable for various applications, such as construction, woodworking, plumbing, and even DIY projects.

3. Precision Cutting

Using a small cut off saw allows for greater precision and control over the cutting process. With their compact blades, these saws provide more accurate and controlled cuts, reducing the risk of errors or mistakes. Whether you need to make straight cuts or intricate angles, a small cut off saw can help you achieve the desired results.

Overall, a small cut off saw offers portability, versatility, and precision that can greatly benefit any professional or hobbyist who deals with cutting materials on a regular basis. Its compact size does not compromise its cutting power, making it a valuable tool in any workshop or job site.

Disclaimer: Always follow safety precautions and wear appropriate personal protective equipment when operating a cut off saw.