MDF (Medium Density Fiberboard) is a versatile and popular material used in various woodworking projects. It is made by compressing wood fibers and resin under high pressure and temperature, resulting in a dense and smooth board. Due to its composition, MDF can be more challenging to cut than solid wood, especially with certain tools.

One common question among woodworkers is whether you can cut MDF with a table saw. The short answer is yes, you can. However, there are a few important factors to consider before you start cutting. MDF generates a large volume of fine dust and can dull the saw blade quickly. Therefore, precautions should be taken to ensure safety and optimize cutting results.

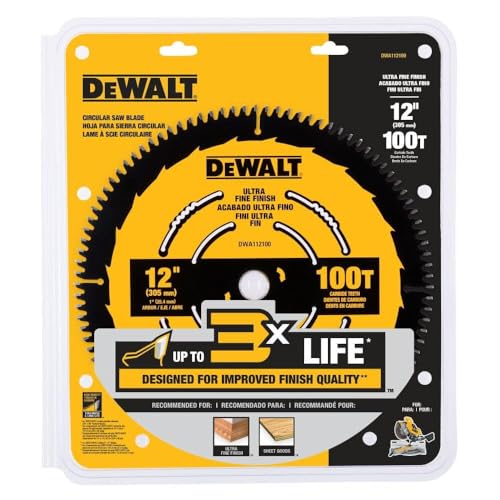

Firstly, it is essential to use a sharp, carbide-tipped blade specifically designed for cutting MDF. This type of blade has more teeth and a higher hook angle, which helps to reduce chipping and tear-out. Additionally, using a zero-clearance insert on the table saw can minimize tear-out and support the material better during cutting.

Is it possible to cut MDF using a table saw?

MDF (Medium-Density Fiberboard) is a commonly used engineered wood product that consists of wood fibers mixed with resin and compressed into panels. It is known for its smooth surface, uniform density, and easy machinability. Many DIY enthusiasts and professionals use MDF for various projects, including cabinetry, furniture, and trim work.

A table saw is a versatile and commonly used tool in woodworking and can be used for cutting a wide range of materials, including MDF. However, there are a few considerations to keep in mind when cutting MDF using a table saw.

Blade Selection:

When cutting MDF, it is important to use a fine-toothed blade with a high tooth count. A blade with more teeth will result in a smoother cut and reduce the chances of chipping or splintering. A blade with a negative hook angle is also preferred, as it helps to reduce tear-out and produce cleaner cuts.

Cutting Technique:

When cutting MDF on a table saw, it is recommended to use a zero-clearance insert to minimize tear-out and support the workpiece. Additionally, you should adjust the blade height to slightly above the thickness of the MDF to prevent excessive friction and burning. It is also important to feed the material through the saw at a steady pace to avoid binding or kickback.

Furthermore, it is advisable to wear appropriate safety gear, such as safety glasses and ear protection, when operating the table saw.

In conclusion, it is definitely possible to cut MDF using a table saw. However, it is essential to use the appropriate blade and cutting technique to achieve clean and smooth cuts without damaging the material. By following these guidelines and taking necessary safety precautions, you can effectively use a table saw to cut MDF for your woodworking projects.

The advantages of using a table saw for cutting MDF

MDF, or medium density fiberboard, is a versatile and commonly used material in woodworking projects. When it comes to cutting MDF, using a table saw can offer several advantages.

Precision:

A table saw is an ideal tool for cutting MDF due to its ability to provide precise and straight cuts. The flat and stable work surface, along with the adjustable cutting depth, allows for accurate and clean cuts every time. This is essential when working with MDF, as it can be prone to chipping or splintering if not cut properly.

Efficiency:

Using a table saw for cutting MDF can greatly increase efficiency and productivity. The large cutting surface and powerful motor of a table saw enable you to cut through MDF quickly and effortlessly. This is especially advantageous when working on large projects or when multiple cuts need to be made.

Safety:

Table saws are designed with safety features that make them a preferred choice for cutting MDF. The blade guard and anti-kickback pawls protect the user from potential accidents and kickbacks, ensuring a safe working environment.

Versatility:

Table saws can be equipped with different types of blades, allowing you to cut MDF with precision and finesse. From rip cuts to crosscuts, a table saw offers versatility in handling various cutting tasks, making it suitable for both small-scale and large-scale projects.

In conclusion, utilizing a table saw for cutting MDF provides numerous benefits, including precision, efficiency, safety, and versatility. Whether you are a professional woodworker or a DIY enthusiast, a table saw is a valuable tool for obtaining accurate and clean cuts while working with MDF.

The recommended techniques for cutting MDF with a table saw

Medium-density fiberboard (MDF) is a popular choice for a variety of woodworking projects due to its affordability and versatility. When it comes to cutting MDF, using a table saw can be an efficient and accurate method. However, there are several recommended techniques that should be followed to ensure the best results and minimize the risk of accidents.

1. Safety first: Before starting any cutting operation, it is crucial to prioritize safety. Always wear protective gear, including safety glasses and gloves. Ensure that the table saw is in good working condition, with a sharp blade and proper blade guard. Keep your hands away from the blade and use push sticks or tools to guide the material through the cut.

2. Choosing the right blade: To get clean and precise cuts in MDF, it is essential to use the right type of blade. A high-quality, carbide-tipped, crosscutting blade with a high tooth count is recommended. The fine teeth on the blade will help minimize chip-out and tear-out, resulting in a smooth cut surface.

3. Setting up the table saw: Before cutting the MDF, set up the table saw according to the desired cut dimensions. Ensure that the rip fence is parallel to the blade and securely locked in place. Adjust the blade height to slightly higher than the thickness of the MDF to prevent binding or overheating.

4. Making the cut: When cutting MDF, it is crucial to control the feed rate to prevent burning or chipping. Start by making a scoring cut along the intended cutting line, using a steady and controlled motion. This will help reduce tear-out and provide a guide for the final cut. Then, proceed with the full cut, maintaining a smooth and even feed rate throughout.

| Material Thickness | Blade Height | Feed Rate |

|---|---|---|

| Less than 1 inch | 1/8 inch higher than MDF | Slow and steady |

| 1 to 2 inches | 1/4 inch higher than MDF | Steady but slightly faster |

| More than 2 inches | 1/2 inch higher than MDF | Steady and slightly faster |

5. Dealing with tear-out: Despite taking precautions, tear-out can still occur when cutting MDF. To minimize tear-out, consider using a sacrificial backing board, such as plywood, beneath the MDF. This will provide support and help prevent chip-out on the underside of the cut.

6. Finishing the cut edges: MDF has a tendency to have rough edges after being cut. To achieve smooth and clean edges, consider using sandpaper or a sanding block to lightly sand the cut surfaces. This will help remove any splinters or roughness and provide a professional finish.

By following these recommended techniques for cutting MDF with a table saw, you can achieve clean, accurate, and safe cuts for your woodworking projects.