As a professional carpenter, I know the importance of having the right tools for the job. When it comes to cutting thin ply, having the best circular saw blade can make all the difference in the world. That’s why I’ve taken the time to test and review various blades, so you don’t have to go through the hassle of trial and error.

Thin ply, also known as veneer or plywood, can be delicate and prone to splintering if not cut with a blade specifically designed for this purpose. The best circular saw blade for thin ply needs to have fine teeth and a low tooth count to ensure clean and precise cuts, without causing any damage to the material.

After extensive research and testing, I have narrowed down the selection to the top three saw blades that are perfect for cutting thin ply. These blades not only provide exceptional cutting performance, but also offer durability and longevity, making them a worthwhile investment for any professional or DIY enthusiast.

What to consider when choosing a circular saw blade for thin plywood

When it comes to cutting thin plywood with a circular saw, choosing the right blade is essential. The blade you select can greatly impact the quality of your cuts and the overall efficiency of your work. Here are a few important factors to consider when choosing a circular saw blade for thin plywood.

1. Blade thickness:

The thickness of the blade is crucial when cutting thin plywood. A thinner blade will produce less resistance, resulting in smoother and cleaner cuts. Look for a blade specifically designed for cutting thin materials, such as a plywood blade or a fine-toothed blade.

2. Tooth count:

The tooth count refers to the number of teeth on the blade. For cutting thin plywood, a higher tooth count is recommended. More teeth on the blade will result in finer, more precise cuts. Consider a blade with at least 60 to 80 teeth for optimal performance.

3. Tooth design:

The design of the teeth can also affect the cutting performance. Blades with alternate top bevel (ATB) or triple chip grind (TCG) teeth are often suitable for cutting thin plywood. These tooth designs help reduce tear-out and provide smoother cuts.

4. Carbide tips:

Blades with carbide-tipped teeth are known for their durability and longevity. They can withstand the challenges of cutting through plywood and maintain their sharpness for longer periods. Look for a blade with carbide tips for enhanced performance and longevity.

By considering the blade thickness, tooth count, tooth design, and carbide tips, you can choose the best circular saw blade for cutting thin plywood. Remember to prioritize quality cuts and efficiency to ensure a successful woodworking project.

I highly recommend using fine tooth count blades for clean and precise cuts

When it comes to cutting thin plywood, finding the right blade can make all the difference in achieving clean and precise cuts. One type of blade that I have found to be highly effective is a fine tooth count blade. These blades are specifically designed to have a higher number of teeth per inch, allowing for smoother and more accurate cuts in thin materials.

Using a fine tooth count blade has several advantages. First and foremost, it produces a clean cut with minimal tear-out. The fine teeth on the blade remove material in a much more controlled manner, resulting in a smooth and splinter-free edge. This is especially important when working with thin plywood, as any tear-out or splintering can ruin the piece.

Additionally, fine tooth count blades are ideal for making precise cuts. The high number of teeth on the blade ensures that the blade engages with the material evenly, preventing any wobbling or saw marks. This allows for precise and accurate cuts, whether you’re making straight cuts or intricate shapes. Whether you’re a professional woodworker or a DIY enthusiast, having a fine tooth count blade in your arsenal is essential for achieving the best results.

Overall, if you’re looking to cut thin plywood with precision and cleanliness, I highly recommend using a fine tooth count blade. Its ability to produce clean cuts with minimal tear-out and its precision cutting capabilities make it an excellent choice for any project that requires a high level of accuracy. So, if you want to ensure that your cuts are clean and precise, invest in a fine tooth count blade and experience the difference it can make in your woodworking.

Carbide-tipped blades for durability and longevity

When it comes to selecting the best circular saw blade for cutting thin plywood, one of the most important factors to consider is durability and longevity. A blade that is made from carbide-tipped material is an excellent choice for these purposes.

Carbide-tipped blades are known for their exceptional hardness and resistance to wear. The carbide teeth are designed to stay sharp for a longer time compared to other types of blades. This means that you can complete more cuts before needing to replace the blade, saving you time and money in the long run.

Another advantage of carbide-tipped blades is their ability to handle the challenges posed by cutting thin plywood. The sharp and durable teeth of the blade ensure clean and precise cuts, reducing the risk of splintering or chipping the wood. This is particularly important when working with delicate materials like thin plywood, where a smooth finish is crucial.

Additionally, carbide-tipped blades are designed to withstand the high temperatures generated during cutting. This heat resistance contributes to the overall durability of the blade and prevents it from getting dull too quickly. As a result, you can rely on a carbide-tipped circular saw blade to deliver consistent and efficient performance, even after prolonged use.

My Experience with Thin Kerf Blades for Reduced Waste and Increased Efficiency

As a woodworker, I always strive to find ways to maximize efficiency and reduce waste in my projects. One tool that has greatly helped me in achieving this goal is a thin kerf blade for my circular saw. These blades are specifically designed to have a thinner cut, which not only reduces waste but also improves the overall efficiency of the cutting process.

One of the main benefits of using a thin kerf blade is the reduction in material waste. With its narrow cut, the blade removes less material from the workpiece, resulting in smaller offcuts and less sawdust. This is especially beneficial when working with thin plywood, as the thin kerf blade allows for precise and clean cuts with minimal material loss.

Another advantage of using a thin kerf blade is the increased efficiency it provides. Due to its narrower profile, the blade requires less power to cut through the material, allowing for faster cutting speeds. This not only saves time but also reduces strain on the saw’s motor, resulting in a longer lifespan for the tool.

In my experience, using a thin kerf blade has been a game-changer in terms of both waste reduction and efficiency. Its ability to make precise cuts with minimal material loss has allowed me to make the most out of every piece of plywood I work with. Additionally, the increased cutting speed and reduced strain on the saw have made my projects much more efficient and enjoyable.

Overall, if you’re looking to minimize waste and increase efficiency in your woodworking projects, I highly recommend investing in a thin kerf blade for your circular saw. It’s a small investment that can make a big difference in the quality and productivity of your work.

Top 5 circ saw blades for thin ply

If you are working with thin plywood, it is important to choose the right circular saw blade that can provide clean and accurate cuts without damaging the material. In this article, we have compiled a list of the top 5 circular saw blades that are perfect for cutting thin plywood. Whether you are a DIY enthusiast or a professional woodworker, these blades will help you achieve excellent results.

1. Freud D12100X 100 Tooth Diablo Ultra Fine Circular Saw Blade:

This blade is specifically designed for cutting plywood, and its ultra-fine teeth help to minimize splintering and chip-out. The laser-cut stabilizer vents reduce vibration and heat buildup, resulting in smoother cuts. It is made from high-density carbide and features a non-stick Perma-Shield coating for ultimate performance and durability.

2. Irwin Tools Marathon Carbide Corded Circular Saw Blade:

This blade is known for its long-lasting performance and ability to make clean cuts in plywood. It features tough tungsten carbide teeth that stay sharp for longer periods of time. With its thin kerf design, it reduces the load on the motor and provides fast, effortless cuts. It is also equipped with anti-kickback shoulder for added safety.

3. DEWALT DW3128P5 80 Tooth and 32T ATB Thin Kerf Crosscutting/Miter Saw Blade:

This combination pack includes an 80-tooth blade for crosscutting and a 32-tooth blade for general-purpose cutting. Both blades feature ultra-sharp carbide teeth that stay sharp for a long time. The thin kerf design minimizes material waste and allows for smoother cuts. They are compatible with most circular saws and miter saws.

4. Bosch DCB1072 Daredevil 10-Inch 72-Tooth Circular Saw Blade:

This blade is designed for clean and precise cuts in plywood and other materials. Its unique C3 carbide teeth provide increased cutting speed and extended blade life. The thin kerf design reduces the strain on the motor and allows for more efficient cutting. With its expansion slots, it reduces heat buildup and warping.

5. CRAFTSMAN 7-1/4-Inch Circular Saw Blade:

This blade is ideal for cutting thin plywood and other thin materials. It features 18 ultra-sharp carbide teeth that stay sharp for a long time. The thin kerf design reduces drag and provides smoother cuts. It is compatible with most circular saws and delivers excellent performance at an affordable price.

In conclusion, when it comes to cutting thin plywood, the quality of the circular saw blade matters. The top 5 blades mentioned above offer exceptional performance, durability, and precision. Whichever blade you choose from this list, you can be confident that it will make your woodworking projects a breeze. Remember to always prioritize safety and follow the manufacturer’s instructions for the best results.

10 Best Circ Saw Blade For Thin Ply

Features

| Part Number | LU79R010 |

| Model | LU79R010 |

| Warranty | Freud Limited Tooling Warranty. Contact Freud customer service for more details. 800-334-4494 |

| Color | Multi |

| Size | One Size |

- Specs: Arbor 5/8", Diameter 10", Grind Hi-ATB, Hook Angle 2°, Kerf .098", Plate .071", Teeth 80

- Premium TiCo HI-Density Carbide Crosscutting Blend for Maximum Performance

- High Alternate Top Bevel (HiATB)Tooth Design produces splinter-free cuts

- Laser-Cut Anti-Vibration Slots drastically reduce vibration and sideways movement in the cut extending blade life and giving a crisp, splinter-free flawless finish

- Perma-Shield Non-Stick Coating reduces blade drag, protects the blade from corrosion and pitch build-up.

Features

| Part Number | FRE-D1080X |

| Model | LU80R010 |

| Warranty | Freud Limited Tooling Warranty. Contact Freud customer service for more details. 800-334-4494 |

| Color | Multi |

| Size | One Size |

- Specs: Arbor 5/8", Diameter 10", Grind Hi-ATB, Hook Angle 2°, Kerf .126", Plate .087", Teeth 80

- Premium TiCo Hi-Density Carbide Crosscutting Blend for Maximum Performance

- High Alternate Top Bevel (HiATB)Tooth Design produces splinter-free cuts

- Laser-Cut Anti-Vibration Slots drastically reduce vibration and sideways movement in the cut extending blade life and giving a crisp, splinter-free flawless finish

- Perma-Shield Non-Stick Coating reduces blade drag, protects the blade from corrosion and pitch build-up.

Features

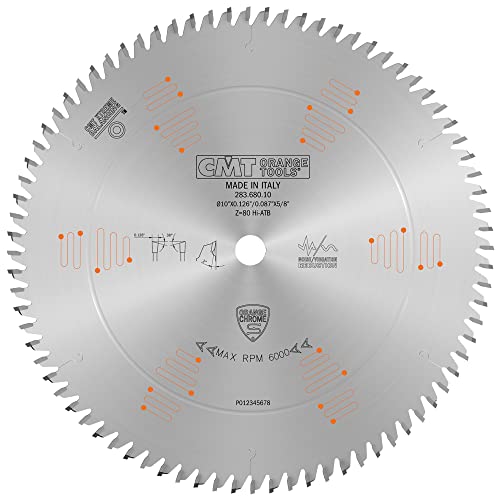

| Part Number | 283.680.10 |

| Model | 283.680.10 |

| Color | SILVER |

| Size | D 10 254mm | T 80 | B 5/8 | K .126 | P .087 |

- 10" diameter, 5/8" bore

- Teeth: 80 HiATB Kerf: 0.126”

- Machine Use: Chop Miter & Table Saw

- Application: Fine Finish

- Materials: Chipboard, Melamine

Features

| Part Number | 7FS-PPY-ZCK |

| Model | 7FS-PPY-ZCK |

| Color | Pack of 20 |

| Size | 12" x 20", 1/8" thick |

- STRONG, DURABLE, HEAVY-DUTY – These craft wood pieces of multi-coated Baltic Birch plywood offer exceptional durability, rigidity, and stability for all your woodworking needs. The surfaces provide excellent holding power for glue and screws and the birch edges create cleaner joinery.

- BEAUTIFUL WOOD, BEAUTIFUL PROJECT- Baltics-grown birch plywood is prized by woodworkers everywhere. Manufactured using the latest methods in wood production, this hardwood from the snowy forests of the north is extremely durable and creep resistant. It has a beautiful lengthwise grain and takes stain well. TRUE SIZE: 11-7/8" x 19-7/8".

- CHOOSE LASER CUTTER WOOD – The layers of the Baltic Birch sheets of thick plywood are designed to smoothly glide through laser cutters and scroll saws, making it the ideal thin wood sheets for efficient woodcutting. Are you looking for wood for wood burning projects? Woodpeckers has the perfect wood boards for crafts.

- GRADE B/BB – Graded as B/BB, this hardwood has a single piece face and a back veneer. The face veneer has a smooth surface with a light uniform color while the back surface typically has 1-2 Small color-matched patches. The thick face veneer provides a smoother surface for CNC routers or engraving machines to glide on the birch wood.

- SERVICE & SELECTION – We are dedicated to partnering with business owners, home crafters, and woodwork artisans. Our customer care agents are thoroughly familiar with our products, and we will be happy to assist you with any concerns and inquiries. Looking for plywood boards in different sizes? Visit the Woodpeckers storefront for a large selection of plywood squares in both 1/4" and 1/8" thickness.

Features

| Part Number | 22106010 |

| Model | 221.060.10 |

| Warranty | CMT carbide and carbide-tipped router bits and saw blades are designed, engineered and manufactured to uncomprimising standards for optimum cutting performance and maximum service life. If for any reason you are not satisfied with the performance of your CMT router bits, and the bits were used for their recommended applications, you can return them to CMT for a full replacement. Warranty excludes dull, misused, damaged, and/or resharpened bits. CMT is not liable for damages to goods, property or persons, due to improper installation or misapplication of equipment. |

| Color | Orange |

- For heavy-duty crosscuts, perfect finishing on single-sided laminated panels.

- For radial arm saws, miter/table & special saws. Cut chipboard, MDF, laminate, hardwood & plywood.

- 0.126 kerf thickness, 0.087 plate thickness, 10° hook angle, Trapezoidal tooth Grind.

- Micrograin carbide teeth to last longer and deliver smooth cuts. Excellent on one-sided laminates.

- Non-Stick PTFE Coating keeps blade running cool, reduces pitch buildup, protects against corrosion.

FAQ:

What is the best circular saw blade for cutting thin plywood?

The best circular saw blade for cutting thin plywood is a fine-tooth blade with a high tooth count. This type of blade produces clean and precise cuts on delicate materials like thin plywood.

What size circular saw blade should I use for cutting thin plywood?

The size of the circular saw blade you should use for cutting thin plywood depends on the thickness of the plywood. For thin plywood, a blade with a diameter of 6 1/2 inches to 7 1/4 inches is usually sufficient. It’s important to choose a blade that is slightly larger than the thickness of the plywood to ensure clean and accurate cuts.

Can I use a regular circular saw blade for cutting thin plywood?

While you can use a regular circular saw blade for cutting thin plywood, it may not produce the best results. Regular blades often have a lower tooth count and larger gullets, which can cause tear-out and rough cuts on delicate materials like thin plywood. It’s recommended to use a fine-tooth blade specifically designed for cutting thin plywood for the best results.

Are there any specific features to look for in a circular saw blade for cutting thin plywood?

When looking for a circular saw blade for cutting thin plywood, it’s important to look for a blade with a high tooth count and fine teeth. These features will ensure clean and precise cuts without tear-out or splintering. Additionally, consider a blade with a thin kerf, as it will remove less material and reduce the risk of damaging the plywood.

Conclusion

In conclusion, when it comes to finding the best circular saw blade for thin plywood, it is important to consider the material of the blade, its tooth count, and the type of cutting that needs to be done. A carbide-tipped blade with a high tooth count is ideal for achieving clean and precise cuts in thin plywood, as it can handle the delicate nature of the material without causing splintering or damage. Additionally, a blade with a thin kerf can help reduce waste and provide smoother cuts. By choosing the right blade for the job, woodworkers can ensure efficient and accurate cutting of thin plywood.