As a professional carpenter and deck builder, I have had the opportunity to work with a variety of saw blades for cutting decking. One of the most important factors to consider when choosing a saw blade is the number of teeth it has. The number of teeth on a saw blade can greatly affect the quality of the cut, as well as the speed and efficiency of the cutting process.

When it comes to cutting decking, there is no one-size-fits-all answer to the best number of teeth for a saw blade. The number of teeth you should choose depends on several factors, including the type of material you are cutting, the thickness of the material, and the desired finish. However, there are a few general guidelines that can help you make an informed decision.

In general, blades with a higher number of teeth are better suited for cutting thinner decking materials, such as softwood or composite decking. These blades provide a smoother finish and are less likely to cause splintering or chipping. On the other hand, blades with fewer teeth are better suited for cutting thicker decking materials, such as hardwood. These blades have larger gullets, which helps to remove sawdust and prevent the blade from getting clogged.

What Is Decking And Why Do You Need A Saw?

Decking refers to the construction of a flat surface that is usually made of wood or composite materials and is used to extend the living space outdoors. It is commonly used to create a comfortable area for relaxation, entertainment, and dining. Decking can be built at ground level or elevated, and it can be attached to a house or freestanding.

When building a decking, a saw is an essential tool that is needed to cut the wooden boards to the desired length and shape. A saw allows for precise and accurate cuts, ensuring that the pieces fit together seamlessly for a professional finish. Whether you are constructing a simple deck or a more complex design, a saw will help you achieve the desired result.

There are different types of saws that can be used for cutting decking, including circular saws and miter saws. Circular saws are handheld tools with a rotating blade that can make straight cuts in wood. They are ideal for cutting long decking boards to size. Miter saws, on the other hand, are stationary tools with a rotating blade that can make angled cuts. They are useful for cutting the ends of decking boards to create clean and precise joints.

In conclusion, decking is a popular home improvement project that involves the construction of an outdoor living space. A saw is an important tool for this project as it allows for accurate and precise cuts in the wooden boards. Whether you are building a simple deck or a more intricate design, a saw will help you achieve the desired result and create a beautiful outdoor space.

Importance of Choosing the Right Number of Teeth

As a professional in the construction industry, I understand the importance of using the right tools for the job. When it comes to saw cutting decking, choosing the right number of teeth for the saw blade is crucial. This decision can greatly impact the quality and efficiency of the cut, as well as the overall performance of the saw.

Accuracy and Precision: Selecting the correct number of teeth for the saw blade ensures accuracy and precision in the cuts. A blade with too few teeth may result in rough and uneven cuts, compromising the final appearance and quality of the decking. On the other hand, a blade with too many teeth can cause friction and heat buildup, leading to slower cutting speed and potential damage to the blade.

Efficiency and Productivity: The number of teeth on the saw blade also affects the cutting speed and productivity. A blade with an optimal tooth count can make quick and clean cuts, saving time and effort on the job site. This increased efficiency not only improves productivity but also minimizes downtime and allows for smoother workflow.

Material Compatibility: Different materials require different tooth configurations for optimal cutting performance. By selecting the appropriate number of teeth, you can ensure that your saw blade is suitable for the specific decking material you are working with. Whether it’s hardwood, softwood, or composite decking, choosing the right tooth count will help you achieve the best results in terms of both speed and quality.

In conclusion, the number of teeth on a saw blade plays a crucial role in the cutting process, directly impacting the accuracy, efficiency, and compatibility with different materials. By carefully considering the specific requirements of the decking project and selecting the right tooth count, you can ensure a successful and efficient outcome.

Factors To Consider When Choosing Number Of Teeth

When it comes to choosing the number of teeth for a saw blade used in cutting decking, there are several factors that need to be taken into consideration. These factors can have a significant impact on the quality of the cuts and the overall efficiency of the cutting process.

Material: The type of material being cut is one of the most important factors to consider when choosing the number of teeth for a saw blade. Different materials require different tooth configurations to achieve optimal cutting results. For example, softer materials like pine may require blades with more teeth to ensure smooth and clean cuts, while harder materials like hardwood may require blades with fewer teeth to prevent overheating and minimize the risk of splintering.

Cutting Speed: The desired cutting speed is another crucial factor to consider. Blades with fewer teeth are generally more suitable for higher cutting speeds, as they remove material at a faster rate. On the other hand, blades with more teeth are better suited for slower cutting speeds, as they provide a finer finish and reduce the risk of tear-out.

Other factors, such as blade diameter, thickness, and rake angle, can also influence the number of teeth suitable for a specific cutting task. It is important to consider these factors in conjunction with the material being cut and the desired cutting speed to ensure optimal performance and achieve the best results.

Recommended Number Of Teeth For Various Types Of Decking

When it comes to cutting decking, choosing the right saw blade can make a significant difference in the quality of the cut and the overall efficiency of the process. The number of teeth on a saw blade plays a crucial role in determining the cut’s smoothness and removing material efficiently. In this article, I will recommend the ideal number of teeth for different types of decking to help you achieve the best results.

Hardwood Decking

If you’re working with hardwood decking materials such as teak, ipe, or mahogany, a saw blade with a high number of teeth is recommended. A blade with 40 to 60 teeth will provide you with a smoother cut, reducing the chance of splintering and tear-out. These blades are designed to handle the dense nature of hardwoods, ensuring clean and accurate cuts.

Softwood Decking

For softwood decking materials like pine, cedar, or fir, a saw blade with a slightly lower number of teeth is more suitable. Blades with 24 to 40 teeth are ideal for cutting softwoods, as they will remove material more quickly and prevent the blade from getting bogged down. These blades are designed to provide faster cuts and are more effective in handling softer materials.

Composite Decking

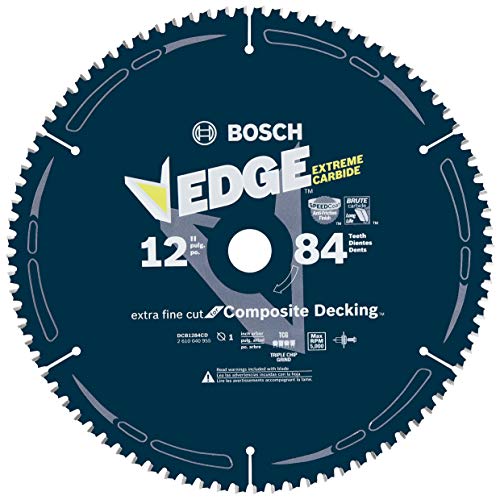

When it comes to cutting composite decking, a special type of saw blade is recommended. Composite blades usually have a high tooth count, ranging from 60 to 80, and are designed specifically to cut through the combination of wood fibers and plastic that make up composite materials. These blades ensure clean and precise cuts, reducing the chances of splintering and chipping.

Remember, using the right saw blade with the appropriate number of teeth for the type of decking material you’re working with is crucial for achieving accurate cuts and minimizing potential damage. Consider these recommendations when choosing the saw blade for your decking project, and always prioritize safety by wearing appropriate protective gear.

Tips For Achieving Clean And Accurate Cuts

When it comes to cutting decking boards, achieving clean and accurate cuts is essential for a professional finish. Here are some tips to help you improve your cutting skills:

- Choose the right saw: Select a saw that suits your needs and the type of material you are cutting. A circular saw or a miter saw is commonly used for cutting decking boards.

- Use the appropriate blade: Ensure that the saw blade you are using is suitable for cutting decking materials. A blade with a high tooth count and designed for clean cuts will yield better results.

- Measure and mark accurately: Take precise measurements and use a square to mark your cutting lines. This will help you achieve straight and accurate cuts.

- Support the material: When cutting long pieces of decking boards, make sure to adequately support the material to prevent it from sagging or splintering during the cut. This can be done using sawhorses or additional support blocks.

- Take your time: Rushing through cuts can lead to mistakes and imprecise results. Take your time and focus on making smooth, controlled cuts to achieve the best outcome.

- Use safety precautions: Always wear appropriate safety gear, such as safety glasses and ear protection, when using power tools. Additionally, ensure that the saw is properly set up and adjusted before making any cuts.

By following these tips, you can improve your cutting skills and achieve clean and accurate cuts when working with decking boards. Remember to always prioritize safety and take your time to ensure the best quality finish for your project.

10 Best Number Of Teeth For Saw Cutting Decking

Features

| Part Number | D0724A |

| Model | D0724A |

| Warranty | Manufacturers warranty |

| Color | Multi |

| Size | One Size |

Features

| Part Number | LU84R011 |

| Model | LU84R011 |

| Warranty | Freud Limited Tooling Warranty. Contact Freud customer service for more details. 800-334-4494 |

| Color | Multi |

| Size | One Size |

Features

| Part Number | DCB1284CD |

| Model | DCB1284CD |

| Color | Blue |

FAQ:

What is the best number of teeth for a saw cutting decking?

The best number of teeth for a saw cutting decking depends on several factors such as the type of material being cut, the thickness of the decking, and the desired cut quality. For general-purpose cutting of decking boards, a saw blade with a higher tooth count (around 40-60 teeth) would be suitable. However, if you want smoother cuts on hardwood decking or require faster cutting speeds, a blade with a lower tooth count (around 24-32 teeth) would be more appropriate.

Does the number of teeth on a saw blade affect the cut quality of decking?

Yes, the number of teeth on a saw blade can affect the cut quality of decking. Blades with a higher tooth count generally produce smoother cuts with fewer splinters and tear-outs. On the other hand, blades with a lower tooth count may remove material faster but can result in rougher cuts. It’s important to consider the type of decking material and desired cut quality when choosing the number of teeth on a saw blade.

Conclusion

In conclusion, selecting the best number of teeth for saw cutting decking depends on various factors such as the type of decking material, the desired finish, and the saw’s horsepower. For softwood materials, a higher tooth count would result in a smoother cut, while a lower tooth count might be more suitable for hardwoods. Ultimately, it is important to consider the specific requirements of the project and consult with industry professionals or manufacturers to determine the most appropriate tooth count for optimal results. Whether it’s a high tooth count for precision or a lower tooth count for faster cutting, understanding the different options available will ensure a successful decking project.