As a professional woodworker, I know the importance of having high-quality chisels. When it comes to creating clean and precise cuts, the type of steel used in the chisel plays a crucial role. There are various types of steel available in the market, but not all are suitable for making chisels. In this article, I will discuss the best steel for making chisels and why it is important to choose the right one.

One of the most popular steels for chisels is high carbon steel. This type of steel is known for its excellent durability and edge retention. High carbon steel has a higher carbon content than other types of steel, which makes it harder and more resistant to wear. This means that chisels made from high carbon steel can maintain their sharpness for a longer period of time, allowing woodworkers to work on their projects without constantly stopping to sharpen their tools.

Another type of steel that is commonly used for making chisels is tool steel. Tool steel is a type of high carbon steel that is specifically designed for use in tools and machinery. It has a high hardness and can withstand repeated use without losing its edge. Chisels made from tool steel are known for their strength and durability, making them ideal for heavy-duty woodworking tasks.

What Makes a Good Chisel Steel?

As a professional woodworker, I understand the importance of using the best steel for making chisels. The quality of the steel used in a chisel can greatly affect its performance and durability. There are several key factors that make a good chisel steel, and understanding these factors can help you make an informed decision when choosing a chisel for your work.

First and foremost, a good chisel steel should have high hardness. Hardness is crucial because it determines how well the chisel can maintain its sharp edge. A hard steel will resist wear and deformation, allowing the chisel to stay sharp for longer periods of time. Typically, high carbon steel or high-speed steel are excellent choices for chisels due to their superior hardness.

To ensure the chisel steel is resilient and can withstand the high impact forces associated with woodworking, it should also possess good toughness. Toughness refers to the ability of the steel to absorb energy without breaking or fracturing. This is important because chisels often encounter heavy blows and need to withstand the force without chipping or breaking. Steels with added elements such as vanadium, manganese, or chromium can enhance toughness.

In addition to hardness and toughness, a good chisel steel should also have good edge retention. Edge retention refers to how well the chisel can retain its sharpness over time with regular use. A steel with good edge retention will require less frequent sharpening and will be more efficient in cutting through wood. High-speed steel, for example, is known for its excellent edge retention properties.

Overall, finding the right chisel steel is a balance between hardness, toughness, and edge retention. Choosing a steel that excels in all these areas will ensure that your chisels are durable, stay sharp for longer, and can handle the demands of professional woodworking. Considering these factors and selecting the best steel for your chisels will greatly enhance your woodworking experience and result in high-quality craftsmanship.

My Top Choices for Chisel Steel

When it comes to making chisels, choosing the right steel is crucial for durability, sharpness, and overall performance. After extensive research and testing, I have narrowed down my top choices for chisel steel options.

1. High Carbon Steel

High carbon steel is an excellent choice for chisels due to its ability to hold a sharp edge and withstand heavy use. This type of steel is known for its high hardness, making it incredibly durable and resistant to wear. Chisels made from high carbon steel are ideal for carving and woodworking tasks that require precision and long-lasting sharpness.

2. Tool Steel

Tool steel is another great option for chisels as it offers an excellent balance of durability and toughness. This type of steel is specifically engineered for use in tools and machinery, making it well-suited for heavy-duty chiseling applications. Chisels made from tool steel are known for their strength and ability to withstand repeated strikes without chipping or breaking.

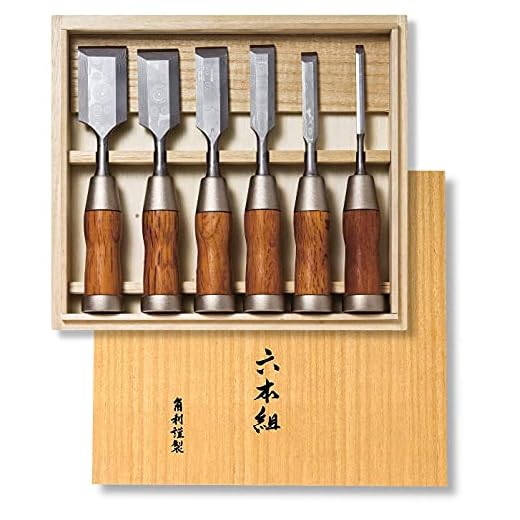

3. Damascus Steel

Damascus steel is a popular choice for chisels due to its unique pattern and exceptional performance. This type of steel is created by folding and layering different types of steel together, resulting in a stunning and durable material. Chisels made from Damascus steel not only provide excellent sharpness and edge retention but also showcase a beautiful and distinctive pattern that adds to their aesthetic appeal.

4. Alloy Steel

Alloy steel is a versatile option for chisels, offering a combination of strength, toughness, and corrosion resistance. This type of steel is made by mixing iron with other elements, such as chromium, nickel, or manganese, to enhance its mechanical properties. Chisels made from alloy steel are highly durable and can withstand demanding tasks without losing their sharpness or performance.

- High carbon steel: excellent sharpness and durability.

- Tool steel: strong and resistant to chipping or breaking.

- Damascus steel: unique pattern and exceptional performance.

- Alloy steel: versatile and offers a combination of strength and toughness.

High Carbon Steel

As a metalworker, I have found high carbon steel to be one of the best materials for making chisels. This type of steel contains a higher percentage of carbon compared to other steels, which gives it enhanced hardness and durability. The high carbon content allows the steel to hold a sharp edge for a longer period of time, making it perfect for chisels that require precision and longevity.

One of the main advantages of high carbon steel is its ability to undergo heat treatment. This process involves heating the steel to a specific temperature and then rapidly cooling it, which improves its hardness and strength. Heat-treated high carbon steel chisels are incredibly tough and resistant to wear, making them ideal for demanding tasks such as wood carving or metalwork.

High carbon steel chisels also offer great edge retention. The high carbon content allows the steel to form very fine carbides, which are small particles that contribute to the overall hardness of the material. These carbides help to maintain a sharp cutting edge for an extended period of time, reducing the need for frequent sharpening and increasing the overall efficiency of the chisel.

Furthermore, high carbon steel is relatively easy to sharpen. With the right tools and techniques, it is possible to achieve a razor-sharp edge on a high carbon steel chisel. This allows for precise and clean cuts, making high carbon steel chisels a favorite among craftsmen and artists.

Tool Steel

I am very passionate about tool steel and its significance in making high-quality chisels. Tool steel is a type of carbon and alloy steel that is specifically designed for the production of tools and machine parts. It is known for its exceptional hardness, wear resistance, and toughness, making it an ideal choice for chisels that need to withstand heavy-duty use and frequent impacts.

One of the most important aspects of tool steel is its composition. It typically contains high amounts of carbon, along with other alloying elements such as chromium, vanadium, and tungsten. The carbon content contributes to the hardness of the steel, while the alloying elements enhance its strength and durability. This combination of properties allows tool steel to maintain a sharp cutting edge and resist deformation or cracking, even under extreme conditions.

Tool steel is available in various grades, each offering different characteristics and suitability for specific applications. Some common grades used in chisel making include O1, A2, and D2. O1 tool steel is known for its excellent wear resistance and good toughness, making it suitable for general-purpose chisels. A2 tool steel has high wear resistance and is ideal for chisels used in woodworking. D2 tool steel offers exceptional hardness and edge retention, making it a popular choice for industrial-grade chisels.

Overall, tool steel is an essential material for making high-performing chisels. Its combination of hardness, wear resistance, and toughness ensures that chisels can withstand demanding tasks and deliver precise and efficient results. Whether it’s woodworking, metalworking, or any other task that requires a chisel, tool steel is the best choice for reliable and long-lasting performance.

Choosing the Right Steel for Your Chisels

Making chisels requires careful consideration of the type of steel used. The right steel can significantly impact the performance, durability, and sharpness of your chisels. In this article, we have discussed some of the best steel options for making chisels.

It is important to note that there is no one-size-fits-all answer when it comes to choosing the right steel for your chisels. The choice depends on various factors such as the intended use of the chisel, the type of wood you will be working with, and personal preferences.

Summary

Here are some key points to consider when choosing the right steel for your chisels:

- High-carbon steel (HCS): Ideal for general woodworking chisels, HCS offers good edge retention, sharpness, and durability.

- A2 steel: Known for its excellent edge retention and toughness, A2 steel is a popular choice for professional woodworkers.

- O1 steel: Offers good edge retention and is relatively easy to sharpen. It is a versatile option for both beginners and experienced woodworkers.

- PM-V11 steel: This premium steel offers exceptional edge retention and is highly recommended for demanding woodworking tasks.

- Laminated steel: Consisting of a high-carbon steel core sandwiched between two layers of softer steel, laminated steel provides the best of both worlds – a hard, durable edge and a flexible body.

When choosing the right steel for your chisels, it is important to consider factors such as the type of woodworking projects you will be undertaking, your skill level, and your budget. Additionally, proper maintenance and sharpening techniques are essential to ensure the longevity and performance of your chisels, regardless of the steel type chosen.

Ultimately, the best steel for making chisels is a personal choice that depends on your specific needs and preferences. Experimenting with different steels and seeking recommendations from experienced woodworkers can help you find the perfect steel for your chisels and enhance your woodworking experience.

10 Best Steel For Making Chisels

Features

| Part Number | 710838 |

| Model | 710838 |

| Color | Evergreen Oak |

| Size | 6, 12, 19, 25, 32, 38mm |

Features

| Part Number | 863251 |

| Model | 863251 |

FAQ:

What is the best steel for making chisels?

There are several types of steel that are commonly used for making chisels, but the best steel for chisels is typically high carbon steel. This type of steel is known for its durability, edge retention, and ability to hold a sharp edge.

Why is high carbon steel the best choice for chisels?

High carbon steel is the best choice for chisels because it is harder than other types of steel, allowing the chisels to hold a sharp edge for longer periods of time. It also provides good impact resistance, making it less likely to chip or break when used for cutting and shaping wood or other materials.

Are there any other types of steel that can be used for making chisels?

Yes, apart from high carbon steel, there are other types of steel that can be used for making chisels. Some examples include tool steel, alloy steel, and stainless steel. However, high carbon steel remains the most popular choice due to its overall performance and affordability.

What are the advantages of using high carbon steel for chisels?

Using high carbon steel for chisels offers several advantages. It provides excellent edge retention, meaning the chisels can stay sharp for longer without frequent sharpening. High carbon steel is also more resistant to wear and tear, making the chisels more durable and long-lasting. Additionally, it allows for precise and clean cuts, making it ideal for woodworking and other fine crafting tasks.

Are there any disadvantages of using high carbon steel for chisels?

While high carbon steel is a great choice for chisels, it does have a few potential drawbacks. It is more prone to rust and corrosion compared to stainless steel, so proper maintenance and storage is necessary to prevent damage. Additionally, high carbon steel chisels can be more difficult to sharpen due to their hardness. This may require more time and effort compared to chisels made from softer steel.

Conclusion

In conclusion, when it comes to choosing the best steel for making chisels, there are several options to consider. Each steel type has its own unique properties that can affect the performance and durability of the chisels. High-carbon steel, such as O1 and A2, offer excellent edge retention and are suitable for various woodworking tasks. Tool steel, such as D2 and M2, provide exceptional hardness and toughness, making them ideal for heavy-duty applications. Stainless steel, like 420 and 440, is corrosion-resistant and great for working with wet or humid conditions. Ultimately, the choice of steel will depend on the specific needs and preferences of the user. It is important to consider factors such as the type of wood being worked with, the desired level of sharpness, and the intended use of the chisels. By carefully considering these factors and selecting the right steel, craftsmen can ensure that they have chisels that are not only functional but also long-lasting.