Using a dual grade laser level can significantly improve the accuracy and efficiency of your construction projects. Whether you’re building a foundation or laying out a parking lot, this advanced tool can help you achieve precise and level measurements.

Step 1: Set up the laser level

Begin by finding a stable surface to mount your dual grade laser level. This can be a tripod or a sturdy platform. Make sure the laser level is securely fastened to the surface to prevent any movement or shaking during operation. Once it is set up, use the built-in leveling bubble to ensure the laser level is perfectly horizontal.

Step 2: Calibrate the laser level

Next, it’s crucial to calibrate your dual grade laser level to ensure accurate readings. Follow the manufacturer’s instructions to set the desired grade or slope. This step is essential for projects that require specific inclinations, such as drainage systems or road construction.

Step 3: Start measuring

Now that your dual grade laser level is set up and calibrated, it’s time to start taking measurements. Position the laser level at one end of your work area and turn it on. The laser beam should project a horizontal line across the surface. Use a grade rod and sensor to measure the difference in height between the laser beam and your desired level. Make adjustments as needed to achieve the desired grade or slope.

Remember to always prioritize safety when using a dual grade laser level. Wear appropriate safety gear, such as protective glasses, and ensure the work area is clear of any obstacles or hazards.

By following these steps, you’ll be able to effectively use a dual grade laser level to achieve accurate and level measurements for your construction projects. With this advanced tool, you can save time and ensure the highest quality results.

What Is A Dual Grade Laser Level And How Does It Work?

A dual grade laser level is a precision tool used in construction and surveying to measure and set slopes, grades, and levels. It is designed to provide accurate measurements in both horizontal and vertical planes, allowing for precise alignment and leveling of surfaces.

How Does It Work?

A dual grade laser level emits a highly focused beam of laser light in a straight line. The laser is housed in a rugged, weather-resistant casing that can be easily mounted on a tripod or attached to a wall bracket. The laser beam is projected onto a target or receiver positioned on a designated reference point.

The receiver is equipped with a sensor that detects the laser beam and provides a digital readout of the elevation or grade. By adjusting the laser level’s settings, the user can set the desired slope or grade. The laser beam will then automatically adjust to maintain the desired elevation as the receiver is moved along the surface.

Some dual grade laser levels also come with a remote control, allowing for easy operation from a distance. The remote control enables the user to adjust the settings, turn the laser on or off, and even set the grade remotely.

Applications of Dual Grade Laser Levels

Dual grade laser levels have a wide range of applications in various industries:

- Construction: Dual grade laser levels are commonly used in site preparation, road construction, and building foundation work to ensure accurate grading and leveling.

- Surveying: Dual grade laser levels are indispensable tools for land surveyors, allowing them to quickly and accurately measure slopes and grades.

- Landscape Design: Dual grade laser levels are used to create level terraces, slopes, and drainage systems in landscape design projects.

- Agriculture: Dual grade laser levels are used in agriculture for precision leveling of fields, irrigation planning, and land preparation for planting.

Overall, a dual grade laser level is a versatile and efficient tool for achieving precise slopes, grades, and levels. Its ease of use and accuracy make it an essential tool for any construction or surveying project.

Understanding the Basics of Dual Grade Laser Levels

A dual grade laser level is a tool used in construction and surveying to determine the level and grade of a surface. It is useful for various applications such as leveling foundations, grading roads, and installing drainage systems.

Unlike a single grade laser level, which only measures a single slope, a dual grade laser level can measure slopes in two directions simultaneously. This makes it a versatile tool for projects that require precise grading and leveling in multiple directions.

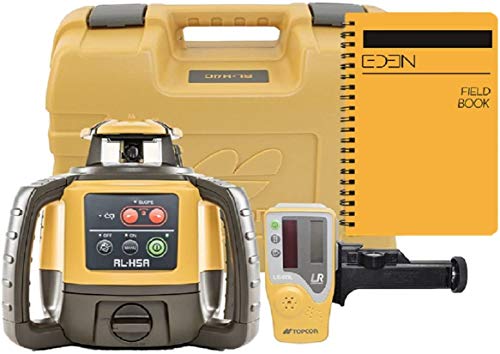

The dual grade laser level consists of a laser unit, a receiver, a tripod, and a remote control. The laser unit emits a laser beam, which is then captured by the receiver. The receiver detects the laser beam and provides a visual or audible indication to the user if the surface is level or if it needs to be adjusted. The tripod is used to position the laser unit at the desired height and angle, while the remote control allows the user to adjust the grade and slope remotely.

Using a dual grade laser level involves several steps. First, the laser unit is set up on a tripod at a suitable location and height. The receiver is then attached to a measuring rod, which is placed on the surface to be measured. The user can then adjust the grade and slope using the remote control, while keeping an eye on the receiver to ensure the surface is level.

It is important to note that using a dual grade laser level requires some knowledge of surveying principles and techniques. The user should have a basic understanding of how to measure slopes and grades, as well as how to interpret the readings provided by the receiver. It is also important to calibrate the laser level and receiver before each use, to ensure accurate measurements.

In conclusion, a dual grade laser level is a valuable tool for construction and surveying projects that require precise leveling and grading in multiple directions. Understanding the basics of how it works and how to use it properly is essential for achieving accurate and reliable results.

Benefits of Using a Dual Grade Laser Level

A dual grade laser level offers several advantages over traditional laser levels, making it a preferred choice for many construction professionals. Here are some of the key benefits:

|

1. Precision and Accuracy: A dual grade laser level provides exceptional precision and accuracy in leveling and aligning tasks. It offers precise measurements, allowing for more accurate construction work and ensuring that structures are built correctly. |

|

2. Versatility: Dual grade laser levels have the ability to perform multiple tasks and can be used for a wide range of applications. Whether you need to level a slope, set a grade, or align objects horizontally or vertically, a dual grade laser level can handle it all. |

|

3. Time-saving: Using a dual grade laser level can significantly reduce the time required for leveling and alignment tasks. Its automated features and advanced technology allow for quick and efficient measurements, saving you valuable time on the job site. |

|

4. Increased Productivity: With its precise measurements, versatility, and time-saving features, a dual grade laser level can greatly increase productivity on the construction site. It enables workers to complete tasks more efficiently, leading to faster project completion and improved overall productivity. |

|

5. Improved Safety: By providing accurate measurements and leveling, a dual grade laser level ensures that structures are built correctly and reduces the risk of accidents and errors. This promotes a safer working environment for construction workers and helps prevent costly rework. |

|

6. Ease of Use: Dual grade laser levels are designed to be user-friendly and easy to operate. They often come with intuitive controls and user-friendly interfaces, making them suitable for both experienced professionals and beginners. |

|

7. Cost-effective: While dual grade laser levels may have a higher upfront cost compared to traditional laser levels, their benefits outweigh the initial investment. They help minimize errors, reduce rework, and increase productivity, ultimately saving you time and money in the long run. |

Step-by-Step Guide on How to Use a Dual Grade Laser Level

A dual grade laser level is a useful tool for ensuring accuracy in construction and surveying projects. It allows for precise measurements and leveling on slopes or uneven surfaces. Here is a step-by-step guide on how to use a dual grade laser level:

Step 1: Set up the laser level

Choose a stable surface or mount to securely place the laser level. Ensure it is positioned at a height appropriate for the task at hand. The laser level should be placed on a tripod or other stable surface for accurate readings.

Step 2: Calibrate the laser level

Before using the laser level, it is important to calibrate it. Follow the instructions provided by the manufacturer to calibrate the laser level properly. This will ensure accurate measurements.

Step 3: Power the laser level

Check the battery or power source on the laser level to ensure it is fully charged or plugged in. Make sure the power supply is stable and won’t be interrupted during use.

Step 4: Set the desired grade

Using the controls on the laser level, set the desired grade or slope. This may involve adjusting the inclination angle or inputting specific measurements. Refer to the user manual to ensure proper settings.

Step 5: Position the laser level

Position the laser level at the starting point of the project. This could be a reference point on the ground or another fixed object. Ensure the laser beam is visible and aligned with the desired line or slope.

Step 6: Monitor the laser beam

As you move along the desired line or slope, monitor the laser beam to ensure it stays aligned and level. Adjust the elevation of the laser level as needed to maintain the desired grade.

Step 7: Take measurements

As you work, use a tape measure or other measuring tool to take accurate measurements at specific intervals. This will help ensure the project is progressing according to plan.

Step 8: Double-check the results

Once the project is complete, double-check the results by measuring key points or using other surveying tools. This will help ensure accuracy and identify any discrepancies that may need to be addressed.

Using a dual grade laser level can greatly improve the accuracy and efficiency of construction and surveying projects. By following this step-by-step guide, you can make the most of this valuable tool and achieve precise results.

Tips and Tricks for Optimizing the Use of a Dual Grade Laser Level

A dual grade laser level is a highly versatile tool that can greatly simplify the process of leveling and grading in construction and surveying projects. Here are some tips and tricks to help you make the most out of your dual grade laser level:

1. Understand the Operating Modes

Before using a dual grade laser level, it’s important to familiarize yourself with the different operating modes it offers. These modes typically include horizontal, vertical, single slope, and dual slope. Understanding how each mode works and when to use them will save you time and effort in the field.

2. Set Up Correctly

Proper setup is crucial for accurate results when using a dual grade laser level. Always ensure the laser level is mounted securely on a stable tripod, and make sure the bubble level indicators are centered. Additionally, double-check that the laser beam aligns with the desired reference point before proceeding with any measurements.

3. Use Remote Control or Mobile Apps

Many dual grade laser levels come with remote controls or mobile apps that allow you to make adjustments and control the device from a distance. Take advantage of these features to avoid constantly walking back and forth to the laser level, thus increasing your productivity on the job site.

4. Consider Environmental Factors

Environmental factors such as bright sunlight, dust, or heavy rain can affect the visibility of the laser beam. To overcome these challenges, use a laser detector or receiver that can amplify the laser signal, making it easier to determine the laser’s position even in unfavorable conditions.

5. Regularly Calibrate the Device

To maintain accuracy, it’s essential to calibrate your dual grade laser level regularly. Follow the manufacturer’s instructions for calibration, and always check for any updates or software upgrades available for your specific model. Keeping your device up to date will ensure consistent and reliable results.

6. Use Target Plates for Long Distances

For long-distance measurements, using target plates can improve accuracy. These plates can reflect the laser beam back to the laser level, allowing you to measure distances that are beyond the device’s line of sight. By using target plates strategically placed along the desired path, you can achieve precise and uninterrupted measurements.

7. Store and Transport Properly

When not in use, always store your dual grade laser level in a protective case to prevent any damage or debris from affecting its performance. During transportation, secure the device to avoid any jostling or impacts that may throw off its calibration. Taking proper care of your laser level will prolong its lifespan and ensure reliable operation.

By following these tips and tricks, you can optimize the use of your dual grade laser level and enhance your productivity on construction or surveying projects.