The medieval period, also known as the Middle Ages, spanned from the 5th to the 15th century. During this time, axes were an essential tool and weapon for various tasks. Medieval axes were crafted with great precision and skill, taking into account the intended use and the materials available.

Blacksmiths played a crucial role in the creation of medieval axes. These highly skilled craftsmen used a combination of traditional techniques and their extensive knowledge of metallurgy to produce axes of exceptional quality. The process typically started with selecting the right type of metal, commonly iron or steel, which was then heated and hammered into shape.

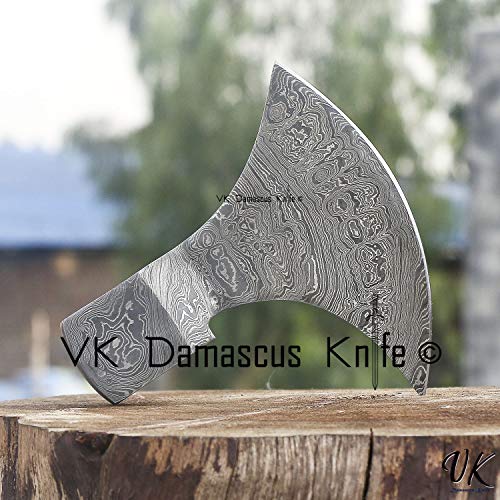

One of the key elements of a medieval axe was the forging of the head. This involved heating the metal until it was malleable and then shaping it using a hammer and anvil. The blacksmith would carefully work the metal, gradually forming the distinct shape of the axe head. The head would often be given a unique design, with decorative details such as engravings or patterns.

After the forging process, the axe head would be hardened by quenching it in water or oil. This process involved rapidly cooling the heated metal, making it much stronger and more durable. Once hardened, the axe head would be carefully sharpened and polished, creating a blade that could effectively penetrate armor or wood.

Finally, the axe head would be securely attached to a wooden handle, typically made from oak or ash. The handle would be carefully shaped and carved to ensure a comfortable grip and proper balance. This step was crucial to the overall functionality of the axe, as a well-balanced weapon would be easier to wield and more effective in combat.

How Medieval Axes Were Made

During the medieval period, axes were essential tools and weapons used for various purposes, such as chopping wood, clearing land, and in warfare. These axes were carefully crafted by skilled blacksmiths who employed a specific process to create durable and effective weapons.

Gathering Materials

To begin the production of a medieval axe, the blacksmith would first gather the necessary materials. This typically included a high-quality steel billet for the axehead, as well as a sturdy wooden handle. The steel billet would be selected based on its composition and strength, ensuring that the final weapon would be able to withstand heavy use.

Forging the Axehead

Once the materials were gathered, the blacksmith would heat the steel billet in a forge until it reached a malleable temperature. The billet would then be placed on an anvil, where the blacksmith would use a hammer to shape it into the desired form of the axehead. This process required precise strikes and careful attention to detail to ensure that the axehead would be properly balanced.

After the basic shape was achieved, the blacksmith would use various tools, such as chisels and files, to refine the edges and surface of the axehead. This included creating a sharp blade for cutting and a sturdy socket for attaching the handle. The blacksmith would regularly heat the axehead throughout this process to maintain its malleability.

Attaching the Handle

Once the axehead was forged and shaped, it was ready to be attached to the wooden handle. The blacksmith would carefully measure and prepare the handle, ensuring that it was properly sized and shaped for the axehead. This typically involved shaping the handle with a lathe or carving tools.

To attach the handle, the blacksmith would create a hole or socket in the axehead that matched the size and shape of the handle. The handle would be inserted into the socket and secured with a wedge or rivet, ensuring a tight and sturdy connection. The blacksmith would test the durability and balance of the finished axe, making any necessary adjustments before the completion of the weapon.

In conclusion, medieval axes were made through a meticulous and skilled process. Blacksmiths carefully selected materials, forged the axehead, and attached a sturdy wooden handle to create a durable and effective tool or weapon. The craftsmanship and attention to detail employed in the creation of medieval axes contributed to their widespread use and effectiveness during this time period.

Choosing the Right Materials

The process of making a medieval axe begins with carefully selecting the right materials. As the axe is a weapon that requires both strength and durability, the choice of materials is crucial in ensuring its effectiveness in battle.

One of the key materials used in crafting medieval axes is iron. Iron is known for its strength and ability to hold a sharp edge, making it an ideal choice for the axe head. Iron is also readily available, making it a practical material to work with.

In addition to iron, another material commonly used is wood. Wood is used to create the handle, or haft, of the axe. The type of wood chosen is important, as it needs to be strong enough to withstand the force exerted during combat. Oak is a popular choice for its strength and durability, while ash and hickory are also commonly used.

Some medieval axes also feature other materials such as leather or metal for decorative elements or reinforcements. These materials add a unique touch to the overall design of the axe and can also enhance its durability.

Overall, choosing the right materials is essential in the production of a medieval axe. By selecting strong and durable materials such as iron and wood, craftsmen were able to create axes that were not only effective in battle but also long-lasting.

The Process of Heating and Shaping

In medieval times, axes were primarily made by skilled blacksmiths who were responsible for the heating and shaping process. The process involved several steps that required a combination of physical strength, technical expertise, and careful craftsmanship.

1. Selecting the Metal

The first step in making a medieval axe was to select the appropriate type of metal. Blacksmiths typically used iron as the main material for axes, as it was strong and readily available. The iron would be carefully inspected to ensure it was free from impurities that could weaken the final product.

2. Heating the Metal

Once the metal was selected, it was heated in a forge or furnace until it reached a high temperature. This process, known as forging, involved placing the iron in the fire and repeatedly heating and hammering it to increase its malleability. The blacksmith would use a variety of tools, such as tongs and hammers, to control the heating process and shape the metal.

3. Shaping the Axe Head

After the metal reached the desired temperature, the blacksmith would begin shaping the axe head. This was done by applying controlled force with a hammer to the heated metal on an anvil. The blacksmith would carefully shape the metal, gradually forming the axe head’s blade and socket. This required precision and attention to detail to ensure the final product was symmetrical and properly balanced.

Throughout the shaping process, the blacksmith would periodically reheat the metal to maintain its malleability and make it easier to work with. This iterative process allowed the blacksmith to create intricate and sharp edges on the axe head, which were essential for effective chopping and cutting.

4. Quenching and Tempering

Once the shaping was complete, the blacksmith would cool the axe head by quenching it in water or oil. This rapid cooling process made the metal hard and brittle, but also prone to cracking. To reduce this brittleness and increase the axe’s durability, the blacksmith would then temper the metal by reheating it to a specific temperature and allowing it to cool gradually.

The tempering process improved the axe’s toughness and flexibility, ensuring it would withstand the rigors of use without breaking or deforming. The blacksmith would carefully monitor the temperature during tempering to achieve the desired balance between hardness and toughness.

Once the axe head was cooled and tempered, it was often further refined by grinding and polishing to remove any imperfections and enhance its appearance. The blacksmith would also attach a wooden handle to complete the axe, creating a deadly and versatile weapon or tool that was highly prized in medieval society.

Adding the Handle

Once the head of the medieval axe has been forged and shaped, it is time to attach the handle. The handle is an essential component of the axe, as it provides the necessary grip and control for the wielder.

The handle is typically made from a strong and durable wood, such as hickory or ash. The wood is carefully selected and shaped to fit snugly into the eye of the axe head. The eye is a hole or socket in the head that is specifically designed to hold the handle.

Before attaching the handle, it is common practice to soak it in water or oil, which helps to prevent splitting or cracking. This also makes the wood more flexible and easier to work with.

To attach the handle, the blacksmith would heat the eye of the axe head. This causes the metal to expand, creating a larger opening. The handle is then inserted into the hot eye, taking care to align it properly. As the metal cools down, it contracts, gripping the handle tightly.

To secure the handle even further, a metal wedge is often driven into the top of the eye. This wedge helps to prevent the handle from becoming loose or falling out. The wedge is typically made from iron or steel.

Once the handle is securely in place, the blacksmith would often carve and shape it to provide a comfortable and ergonomic grip. This may involve adding ridges or contours to improve grip and handling.

Overall, the process of adding the handle to a medieval axe requires skill and precision. It is a crucial step in the making of the axe and ensures that it is ready to be wielded with strength and control.

Decorating and Reinforcing

In addition to their practical function, medieval axes were often decorated to reflect the status and rank of their wielder. The heads of the axes were often engraved or inlaid with decorative patterns or images, such as heraldic symbols, mythological creatures, or religious motifs.

The decoration of axes was typically done by skilled craftsmen who used various techniques, such as engraving, etching, or damascening, to create intricate designs. These decorative elements not only enhanced the appearance of the axes but also served as a form of personal expression or identification.

Furthermore, medieval axes were often reinforced to increase their durability and effectiveness in battle. The wooden handles of the axes were reinforced with metal bands or ferrules to prevent splitting or breaking. These metal reinforcements were usually made of iron or brass and were securely fastened to the handle.

The heads of the axes were also reinforced with metal, typically by adding a metal collar or socket that protected the area where the handle was attached. This reinforcement not only provided added strength but also allowed for easy replacement of the handle if it became damaged or worn out.

Overall, the decoration and reinforcement of medieval axes played an important role in both the aesthetic appeal and functionality of these weapons.

Sharpening the Blade

After the initial shaping and forming of the axe head, the next step in creating a medieval axe was sharpening the blade. This was an important process that required skill and precision.

The first step in sharpening the blade was to carefully grind the edge of the axe head. This was typically done using a grindstone or a handheld sharpening stone. The blacksmith would hold the axe head firmly and run the edge across the stone, gradually shaping it to a sharp point. This process required patience and control to ensure that the edge was even and symmetrical.

Once the initial grinding was complete, the blacksmith would then move on to honing the blade. Honing involved using a finer-grained sharpening stone to further refine and polish the edge. This step helped to remove any burrs or imperfections left from the grinding process and created a smoother and more precise cutting edge.

After honing, the blacksmith would carefully inspect the blade for any signs of weakness or damage. Any areas that needed to be strengthened or repaired would be addressed before the axe head was considered complete.

Throughout the sharpening process, the blacksmith would frequently test the blade’s sharpness by making cuts on various materials. This allowed them to make any necessary adjustments and ensure that the axe was properly sharpened.

Overall, sharpening the blade was a crucial step in the creation of a medieval axe. It required skill, precision, and attention to detail to create a sharp and effective cutting tool.

Testing and Final Adjustments

After the medieval axes were fabricated, they underwent a series of rigorous tests to ensure their durability and effectiveness. This phase of the production process involved skilled craftsmen who examined each axe individually and made any necessary adjustments to improve its performance.

Visual Inspection

The first step in testing the axes involved a visual inspection to identify any cosmetic flaws or structural imperfections. Each axe was carefully examined to ensure that it met the required standards of appearance and quality.

Performance Evaluation

To evaluate the performance of the axes, a series of practical tests were conducted. The craftsmen tested the cutting and chopping abilities of the axe by striking various materials such as logs, branches, and armor. They assessed the efficiency of each swing and the overall impact of the axe on the target.

Axes that demonstrated superior cutting performance were selected for further refinement and adjustments, while those that did not meet the required standards were sent back for additional work.

Final Adjustments

Once the axes passed the initial tests, the craftsmen made final adjustments to optimize their balance, weight distribution, and overall feel. This step was crucial for ensuring that the axe was comfortable to wield and provided maximum control for the user.

During this stage, the craftsmen might add or remove material from the axe head, adjust the length or thickness of the haft, or make modifications to the shape of the blade to enhance its cutting ability. These adjustments were made based on the specific requirements of different types of axes, such as battle axes or woodcutting axes.

| Testing Parameters | Criteria |

|---|---|

| Cutting Ability | The axe should be able to deliver clean and efficient cuts. |

| Balance | The weight distribution should be well-balanced for easy handling. |

| Control | The axe should provide the user with maximum control during swings. |

| Durability | The axe should withstand repeated use without significant damage. |

By conducting thorough testing and making necessary adjustments, medieval craftsmen ensured that each axe was of the highest quality and ready to serve its intended purpose.