Knives are essential tools in every kitchen, but over time, their blades become dull and less effective. This is where knife sharpeners come in handy.

Knife sharpeners are specially designed devices that help restore the sharpness of a knife blade. They are made of various materials, each with its own unique characteristics and benefits.

One common material used in knife sharpeners is diamond. Diamond sharpeners are known for their durability and effectiveness in sharpening knives quickly. The diamond particles embedded in these sharpeners create an abrasive surface that efficiently removes metal from the blade, resulting in a sharp edge.

Another popular material is ceramic. Ceramic sharpeners are known for their precision and ability to create a razor-sharp edge. The ceramic surface is harder than steel, allowing it to remove metal from the knife blade with precision.

Additionally, some knife sharpeners are made of steel. Steel sharpeners are often used for honing and maintaining the sharpness of knives. They are known for their durability and ease of use.

Overall, knife sharpeners are made of materials like diamond, ceramic, or steel, which play a crucial role in restoring the sharpness of knife blades. Depending on your needs and preferences, you can choose the right type of sharpener to keep your kitchen knives in top shape.

Types of Materials

Knife sharpeners can be made from a variety of materials, each with their own advantages and disadvantages. The choice of material can affect the sharpener’s durability, sharpening performance, and maintenance requirements.

Ceramic

Ceramic knife sharpeners are known for their hardness and ability to maintain a sharp edge. They are usually made from a high-density ceramic material, such as alumina or zirconia. Ceramic sharpeners are favored for their precision sharpening capabilities and their ability to remove small amounts of metal from the blade. However, they can be prone to chipping or breaking if not handled with care.

Steel

Steel knife sharpeners, also known as honing rods or steels, are made from a variety of steel alloys. They are typically textured or coated to provide an abrasive surface for sharpening. Steel sharpeners are popular for their durability and versatility. They can remove minor imperfections and realign the edge of a blade, but they may not be as effective at sharpening severely dull blades.

Diamond

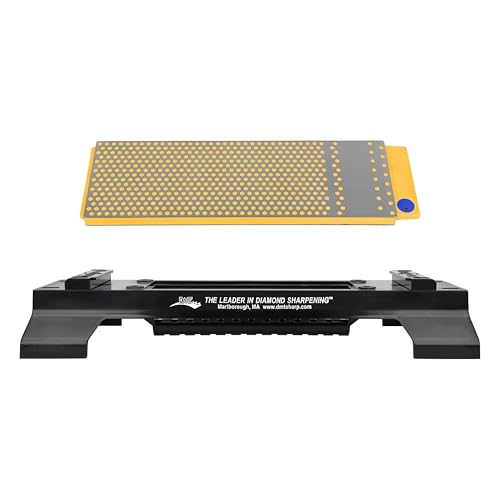

Diamond knife sharpeners are made with a diamond coating or embedded diamond particles. Diamonds are the hardest known material, making diamond sharpeners ideal for quickly sharpening even the dullest blades. They are highly wear-resistant and maintain their shape over time. However, diamond sharpeners can be more expensive compared to other types of sharpeners.

Apart from these primary materials, knife sharpeners may also incorporate elements such as rubber or plastic handles for ergonomic grip, and non-slip bases for stability during use.

| Material | Advantages | Disadvantages |

|---|---|---|

| Ceramic | Hardness, precision sharpening | Potential for chipping or breaking |

| Steel | Durability, versatility | May not be effective on severely dull blades |

| Diamond | Quick sharpening, wear-resistant | Can be more expensive |

Steel and Ceramic

Knife sharpeners are typically made from either steel or ceramic materials, or a combination of both.

Steel is a popular choice for knife sharpeners because of its strength and durability. It can effectively sharpen dull blades and remove small imperfections. Most steel sharpeners have a rough surface that grinds away metal, creating a new edge on the blade. Some steel sharpeners also have a fine surface that hones the edge for a smoother finish.

Ceramic knife sharpeners, on the other hand, are known for their ability to create a razor-sharp edge. The hard surface of ceramic sharpeners can easily remove metal and produce a polished finish. However, ceramic sharpeners are more fragile and prone to breaking compared to steel sharpeners.

Many knife sharpeners on the market today combine steel and ceramic elements. These hybrid sharpeners often have a steel base with ceramic rods or wheels. This combination allows for both initial metal removal and fine finishing for a superbly sharp edge.

In conclusion, knife sharpeners are made from steel, ceramic, or a combination of both. Each material has its own advantages and qualities, so it’s important to choose one that suits your sharpening needs.

Diamond-Coated

One type of material commonly used in knife sharpeners is diamond-coated. Diamond-coated sharpeners are known for their exceptional durability and effectiveness in sharpening knives.

The diamond coating on these sharpeners provides a hard and abrasive surface that can easily remove metal from the knife’s blade, resulting in a sharp and precise edge. The diamond particles are applied to the sharpening surface using a process called electroplating, where a layer of diamond is bonded to a metal substrate.

Diamond-coated sharpeners are often used by professional chefs and knife enthusiasts who require extremely sharp blades for their culinary endeavors. They are also popular among hunters and outdoor enthusiasts who rely on sharp knives for various tasks.

Advantages of Diamond-Coated Knife Sharpeners

There are several advantages to using a diamond-coated knife sharpener:

- Durability: Diamond-coated sharpeners are highly durable and can withstand frequent use without wearing out. The diamond particles on the surface remain sharp for a long time, ensuring consistent performance.

- Efficiency: The diamond coating is extremely effective at removing metal from the blade, allowing for quick and efficient sharpening. It can restore a dull knife’s sharpness in just a few passes.

- Versatility: Diamond-coated sharpeners can be used for different types of knife blades, including stainless steel, carbon steel, and even ceramic. They can handle various blade shapes and sizes.

Usage Tips for Diamond-Coated Knife Sharpeners

When using a diamond-coated knife sharpener, it’s important to keep the following tips in mind:

- Apply light pressure: Diamond-coated sharpeners work best with a light touch. Excessive pressure can cause the diamond particles to break or become less effective. Let the sharpener do the work.

- Follow the manufacturer’s instructions: Different diamond-coated sharpeners may have specific guidelines for usage. Always read and follow the instructions provided by the manufacturer.

- Maintain consistency: To achieve a sharp and even edge, make sure to keep a consistent angle and stroke when sharpening. Practice and repetition can help improve your technique.

- Regular cleaning: Diamond-coated sharpeners can accumulate metal particles during the sharpening process. Clean the sharpener regularly to remove these particles and maintain its performance.

Overall, diamond-coated knife sharpeners offer superior sharpening ability and durability, making them a popular choice among professionals and enthusiasts alike.

Sharpening Stones

Sharpening stones are commonly used tools for sharpening knives and other cutting instruments. They are made of various types of materials, each with its own unique properties, which affect the performance and outcome of the sharpening process.

Natural Stones: Some sharpening stones are made from natural materials, such as Novaculite, which is a type of sedimentary rock found primarily in Arkansas, USA. Novaculite stones are known for their fine grit and excellent sharpening abilities. Another example of a natural sharpening stone is the Japanese Waterstone, which is made from sedimentary rock and provides a high-quality sharpening surface.

Artificial Stones: Many sharpening stones are also made from artificial materials. One common type is the Ceramic Stone, which is made by combining different minerals and firing them at high temperatures. Ceramic stones are known for their durability and ability to produce a very sharp edge. Another example is the Diamond Stone, which has a coating of industrial diamonds that make it extremely hard and effective for sharpening even the toughest blades.

Oil Stones: Some sharpening stones, both natural and artificial, require the use of oil as a lubricant to facilitate the sharpening process. These stones, commonly known as Oilstones, can be made of various materials and are relatively easy to maintain. They offer good sharpening performance and are suitable for a wide range of cutting tools.

Water Stones: Another type of sharpening stone is the Waterstone, which, as the name suggests, requires the use of water as a lubricant. Water stones are typically made from natural materials or artificial abrasives bonded together with a binder. They are popular for their ability to quickly remove material from the blade and produce a sharp edge.

Regardless of the type of sharpening stone used, it is important to choose the appropriate grit size for the specific task at hand. Coarse grit stones are used for repairing damaged edges or reshaping blades, while finer grit stones are used for honing and refining the edge.

Using a sharpening stone requires skill and practice, but with the right technique, it can help maintain the sharpness and longevity of your knives and cutting tools.