Reciprocating saws, also known as sabre saws or recip saws, are powerful tools commonly used in construction and demolition projects. They are designed to cut through a variety of materials, including wood, metal, and plastic. While these saws can be highly efficient and versatile, it is essential to understand the potential fire risks associated with their use.

One of the primary factors that can make reciprocating saws a fire risk is the friction generated during operation. As the saw blade moves back and forth at high speeds, it can generate significant heat. If this heat is not properly dissipated or if it comes into contact with flammable materials, it can ignite a fire.

Another contributing factor to the fire risk associated with reciprocating saws is the production of sparks. When cutting through metal or other hard materials, the saw blade can create sparks due to the friction between the blade and the material being cut. These sparks can potentially ignite nearby flammable substances or gases, leading to a fire.

It is crucial to take appropriate safety precautions when using reciprocating saws to minimize the risk of fire. This includes wearing personal protective equipment, such as safety goggles and gloves, to protect against sparks and flying debris. Additionally, ensuring proper ventilation in the working area can help dissipate heat and reduce the chance of ignition.

Overall, while reciprocating saws can be invaluable tools in various applications, it is essential to be aware of the potential fire risks they pose. By understanding these risks and implementing appropriate safety measures, users can minimize the likelihood of fires and ensure safe operation.

Can reciprocating saws cause fires?

Reciprocating saws, also known as sawzalls, are powerful tools that can be incredibly useful for a variety of tasks. However, it’s important to understand that they do come with certain risks, and one potential danger is the risk of fire.

While reciprocating saws themselves do not typically generate sparks or flames, improper use or malfunctioning of the tool can increase the risk of a fire starting. Here are a few reasons why reciprocating saws can pose a fire risk:

Overheating: Like many power tools, reciprocating saws generate heat during operation. If the tool is used continuously for extended periods of time or if it is overloaded with too much force, it can overheat, potentially leading to a fire.

Electrical issues: Reciprocating saws are electrically powered, and any faults in the electrical system can increase the risk of a fire. This can include issues such as frayed or damaged wires, loose connections, or faulty switches. It is important to regularly inspect the tool and its power cord for any signs of damage.

Ignition of flammable materials: Reciprocating saws are often used in construction and demolition projects, where they may come into contact with flammable materials such as sawdust, insulation, or chemicals. If the blade of the saw sparks while in contact with these materials, it can potentially ignite a fire.

Improper storage and handling: When not in use, it is important to store reciprocating saws in a safe and secure manner. Leaving the tool in a location that is prone to overheating, such as near a heat source or in direct sunlight, can increase the risk of fire. Additionally, mishandling the tool or failing to follow proper safety precautions can also lead to accidents that could result in a fire.

To minimize the risk of fires when using a reciprocating saw, it is crucial to follow all safety guidelines provided by the manufacturer. This includes wearing appropriate personal protective equipment, using the tool in a well-ventilated area, and regularly inspecting the tool to ensure it is in good working condition.

In conclusion, while reciprocating saws themselves do not inherently cause fires, they can become a fire risk if not used properly or if there are underlying electrical issues. By using caution and following safety procedures, the risk of fires can be minimized, allowing you to use this versatile tool safely and effectively.

Understanding the potential fire risk

Reciprocating saws, while highly useful and versatile power tools, do come with a potential fire risk. It is important for users to understand this risk and take necessary precautions to minimize the chances of a fire occurring.

One of the main causes of fire with reciprocating saws is overheating. When a reciprocating saw is used for extended periods of time without proper cooling, the motor can become overheated. This can lead to the insulation of the wiring inside the tool melting and potentially causing a fire.

Another potential fire risk is using the reciprocating saw near flammable materials or in a flammable environment. Sparks or debris generated during the cutting process can ignite flammable substances such as sawdust, oil, or chemicals. It is crucial to always work in a well-ventilated area and to remove any flammable materials from the vicinity.

Regular maintenance and inspection of the reciprocating saw can help prevent fire hazards. It is important to check the tool for any damaged or frayed wiring, loose connections, or blocked ventilation ports. Keeping the tool clean and free from dust and debris can also contribute to reducing the risk of fire.

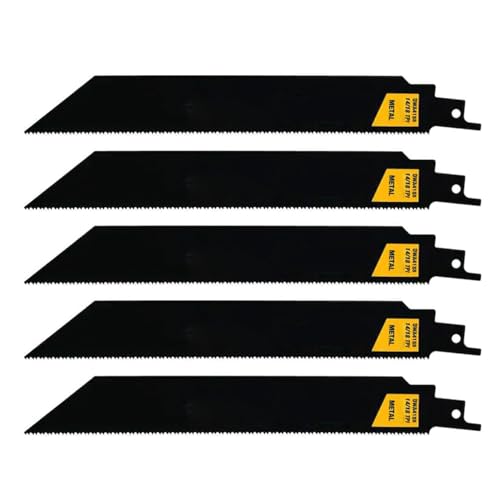

Using the appropriate blades for the material being cut is vital to prevent overheating and potential fires. The wrong blade can cause excessive friction and heat, increasing the risk of fire. It is essential to use the correct blade and ensure it is sharp and in good condition.

Furthermore, following safety guidelines and using personal protective equipment can help reduce the risk of fire. Wearing safety goggles, gloves, and a fire-resistant apron can provide additional protection in case of a fire. It is also important to have a fire extinguisher readily available in the workspace.

- Avoid using the reciprocating saw in wet or damp conditions, as moisture can increase the risk of electrical currents causing a fire.

- Never overload the tool or use it beyond its intended capabilities. This can put excessive strain on the motor and increase the likelihood of overheating and fire.

- If any unusual smells or smoke is detected while using the reciprocating saw, immediately turn off the tool and investigate the source of the problem. Continued use in such cases can lead to a fire.

By understanding the potential fire risk associated with reciprocating saws and taking appropriate precautions, users can ensure a safer and more efficient working environment.

Factors that contribute to fire hazards

Reciprocating saws, like any power tool, can pose a fire risk if not handled properly or if certain factors are overlooked. Here are some of the key factors that can contribute to fire hazards:

- Overheating: Continuous and prolonged use of a reciprocating saw can cause the motor to overheat. This can result in sparks or flames, especially if there is debris or flammable material near the saw.

- Electrical issues: Faulty wiring, damaged cords, or improper electrical connections can all increase the risk of a fire. It is important to regularly inspect the saw’s power cord and ensure that it is in good condition.

- Flammable materials: Operating a reciprocating saw in an environment with flammable materials, such as gasoline, oil, solvents, or sawdust, can greatly increase the potential for a fire. These materials can ignite easily if exposed to sparks or heat generated by the saw.

- Improper storage: Storing a reciprocating saw near flammable materials or in a cluttered and congested area can be dangerous. It is crucial to store the saw in a clean, well-ventilated area, away from potential fire hazards.

- Lack of maintenance: Neglecting regular maintenance, such as cleaning or lubricating the saw, can lead to a build-up of sawdust or debris, which can ignite and cause a fire. It is important to clean the saw after each use and conduct regular inspections to ensure it is in good working condition.

By being aware of these factors and taking appropriate safety precautions, such as using the saw in a well-ventilated area, wearing protective gear, and following manufacturer guidelines, the risk of fire hazards can be significantly reduced.

Safety precautions for using reciprocating saws

Reciprocating saws are powerful and useful tools, but they can also pose risks if not used properly. It is important to follow safety precautions when using these saws to prevent accidents and injuries.

1. Wear appropriate safety gear

Before operating a reciprocating saw, it is important to wear safety gear to protect yourself. This includes safety glasses or goggles to protect your eyes from flying debris, ear protection to reduce noise levels, and gloves to protect your hands.

2. Check the saw and blades

Prior to each use, inspect the reciprocating saw and its blades. Ensure that the saw is in good working condition and free from defects. Check the blades for any signs of damage or dullness, and replace them if necessary. Properly inserting and securing the blades is also essential for safe operation.

3. Use the right blade for the job

Using the correct blade for the material you are cutting is crucial for safety. Different blades are designed for specific materials such as wood, metal, or plastic. Make sure to use the appropriate blade for the material you are working with to ensure efficient and safe cutting.

4. Secure your workpiece

When using a reciprocating saw, make sure to properly secure your workpiece. This can be done by clamping it down or using a vice grip to prevent movement during cutting. This will help reduce the risk of the saw slipping or causing accidents.

5. Maintain a stable position

When operating a reciprocating saw, maintain a stable stance and grip on the tool. Keep your feet shoulder-width apart and firmly planted on the ground. Use both hands to securely grip the saw, ensuring you have full control during cutting.

6. Be aware of your surroundings

Before starting to cut, assess your surroundings and identify any potential hazards. Ensure that there is enough space around you to safely maneuver the saw. Avoid cutting near flammable materials or in close proximity to electrical wires to minimize the risk of fires or electric shocks.

7. Use the saw with caution

When using a reciprocating saw, it is important to exercise caution and take your time. Push the saw slowly and steadily through the material, allowing the blade to do the work. Avoid putting excessive pressure on the saw or forcing it through the material, as this can lead to kickbacks or blade breakage.

By following these safety precautions, you can minimize the risk of accidents and injuries while using a reciprocating saw. Remember to always prioritize safety and take necessary precautions to protect yourself and those around you.

Importance of Regular Maintenance

Regular maintenance is crucial when it comes to ensuring the safe and efficient operation of reciprocating saws. Just like any other power tool, these saws require regular inspections and upkeep to prevent potential fire risks.

Preventing Fire Hazards

Without regular maintenance, reciprocating saws can become prone to malfunctions that could potentially lead to fires. Over time, dust, debris, and general wear and tear can accumulate within the saw’s motor and electrical components. This buildup increases the risk of overheating, electrical short circuits, and sparks, all of which can ignite a fire.

Regular maintenance involves cleaning the saw’s housing and motor to remove accumulated dust and debris. This should be done using compressed air or a brush to ensure that all areas are thoroughly cleaned. Additionally, inspecting the power cord and plug for any signs of damage, fraying, or loose connections is essential to prevent electrical issues.

Ensuring Optimal Performance

Besides fire risks, regular maintenance also ensures that reciprocating saws perform at their best. By keeping the saw clean and lubricated, you can minimize friction and reduce the chances of parts seizing or breaking during operation. Lubricating the saw’s moving parts with appropriate oils or grease will help to extend the longevity of the tool and enhance its overall efficiency.

Regular maintenance also includes checking and replacing worn-out or damaged parts such as blades, belts, or gears. Using dull or damaged blades can put excessive strain on the motor, decreasing its efficiency and increasing the risk of overheating. It is important to inspect and replace these parts as necessary to maintain the saw’s performance and prevent potential safety hazards.

In conclusion, regular maintenance is vital for reciprocating saws to prevent fire risks and ensure optimal performance. By performing routine inspections and taking necessary steps to clean, lubricate, and replace worn-out parts, you can help to prolong the lifespan of your saw and significantly reduce the chances of accidents or fires.

How to handle overheating issues

When using a reciprocating saw, it is essential to be aware of any potential overheating issues. Overheating can not only pose a fire risk but can also lead to malfunctions and reduce the tool’s lifespan. Here are some tips on how to handle overheating issues:

1. Ensure Proper Ventilation

One of the main causes of overheating in reciprocating saws is poor ventilation. Make sure that the tool is not covered or blocked while in use. Keep the air vents clear and free from dirt, dust, or debris that could impede airflow. Good ventilation helps dissipate heat and keeps the saw running smoothly.

2. Use the Right Blade

Using the correct blade for the task at hand is crucial. Using the wrong blade or a dull blade can place excessive strain on the motor, leading to overheating. Consult the manufacturer’s guidelines to ensure you are using the recommended blade for the material and type of cutting you are doing.

Additionally, regularly inspect and replace blades as needed to maintain optimal performance and prevent overheating.

3. Minimize Continuous Use

Reciprocating saws are designed for intermittent use, not prolonged continuous operation. Prolonged use without giving the tool a rest can cause overheating. Take breaks during extensive cutting tasks to allow the tool to cool down. Give the tool a chance to rest and prevent overheating by using it in short, controlled bursts.

Furthermore, never leave the tool unattended while it is running to prevent overheating and potential fire hazards.

Overall, being mindful of proper ventilation, using the right blade, and controlling usage time are key to handling overheating issues effectively. By following these guidelines, you can ensure a safer and more efficient experience when using a reciprocating saw.

Concluding thoughts on fire risks with reciprocating saws

Reciprocating saws are versatile and powerful tools that can make many cutting tasks easier and more efficient. However, it’s important to be aware of the potential fire risks that come with using these tools.

One of the main fire risks associated with reciprocating saws is the buildup of sawdust and debris. As the saw blade moves back and forth, it can create friction and generate heat. If sawdust or other flammable materials come into contact with the hot blade, they can ignite and start a fire. To minimize this risk, it’s crucial to keep the work area clean and clear of debris.

Another fire risk to consider is the possibility of cutting into live electrical wires while using a reciprocating saw. If the blade accidentally comes into contact with a live wire, it can cause sparks and potentially start a fire. Always make sure to turn off the power supply and properly disconnect any electrical sources before starting a cutting job.

Additionally, using the wrong type of blade for a specific material can increase the risk of fire. Blades that are not designed for cutting certain materials can overheat and potentially ignite the material. It’s essential to use the appropriate blade for each job to avoid unnecessary fire hazards.

In conclusion, while reciprocating saws can be valuable tools for various cutting tasks, it’s crucial to be aware of the fire risks they pose. By keeping work areas clean, avoiding contact with live electrical wires, and using the correct blade for the job, you can minimize the chances of a fire starting while using a reciprocating saw. Safety should always be a top priority when working with power tools.