When it comes to fine finish work, having the right saw blade can make all the difference. A high-quality fine finish saw blade can help you achieve clean, precise cuts without any tear-out or splintering. Whether you are working on a woodworking project, installing trim, or cutting hardwood flooring, having a reliable and efficient saw blade is essential.

There are several factors to consider when choosing the best fine finish saw blade. The number of teeth, blade diameter, tooth geometry, and the quality of materials used are all crucial in determining the blade’s performance. A blade with a higher tooth count will typically produce smoother cuts, while a larger diameter blade can help you make quick and efficient cuts.

A fine finish saw blade with a thin kerf is also desirable as it reduces waste, minimizes material removal, and allows for easier cutting. Additionally, a blade with carbide-tipped teeth will offer exceptional durability, long life, and efficient cutting performance. The quality of the blade’s construction is crucial in ensuring that it remains sharp and performs at its best throughout its lifespan.

From ripping to cross-cutting, a fine finish saw blade should be versatile and capable of handling various materials with ease. Whether you are working with softwood, hardwood, plywood, or even laminates, a reliable and efficient saw blade will help you achieve professional and precise results every time. So, invest in the best fine finish saw blade and elevate the quality of your woodworking projects.

Achieving Smooth and Clean Cuts

As a professional woodworker, I understand the importance of achieving smooth and clean cuts in my projects. The quality of the cuts not only affects the overall appearance of the finished product, but it also impacts the ease of assembly and the durability of the joints. To ensure that I can consistently achieve excellent results, I rely on the best fine finish saw blades available in the market.

One of the key factors in achieving smooth and clean cuts is using a saw blade with the right number of teeth and the appropriate tooth configuration. A fine finish saw blade typically has a high tooth count, ranging from 60 to 100 teeth per blade. This high tooth count allows for more teeth to come into contact with the material, resulting in a smoother cut. Additionally, the tooth configuration of a fine finish blade is designed to minimize tear-out and reduce the risk of splintering, ensuring clean cuts with minimal surface damage.

Another important aspect of achieving smooth and clean cuts is selecting the right blade material. Fine finish saw blades are typically made from high-quality carbide or high-speed steel. These materials offer superior durability and sharpness, allowing the blade to maintain its cutting performance for a longer period of time. When the blade is sharp, it can effortlessly slice through the wood fibers, resulting in cleaner cuts with minimal effort on my part.

In conclusion, achieving smooth and clean cuts is essential for any woodworking project. Using the best fine finish saw blades, with the right tooth count and configuration, as well as high-quality blade materials, ensures that I can consistently achieve excellent results. These blades not only make my work easier, but they also contribute to the overall quality and longevity of my projects. Investing in the best fine finish saw blades is a worthwhile decision for any serious woodworker.

Increasing Efficiency and Productivity

In today’s competitive business environment, it is essential to find ways to increase efficiency and productivity in order to stay ahead. As a professional woodworker, I understand the importance of using the best tools and equipment to achieve the highest quality results in the shortest amount of time. One of the key factors in achieving this is by using the right saw blade.

When it comes to fine finish work, using a high-quality saw blade can make all the difference. A fine finish saw blade is specifically designed to produce clean, precise cuts that require minimal sanding or finishing. This not only saves time but also ensures a professional-looking end result. By investing in the best fine finish saw blade, I have been able to significantly increase my efficiency and productivity.

Efficiency

Using a fine finish saw blade allows me to work faster and more efficiently. The sharp teeth and precise cutting geometry of the blade enable me to make clean and accurate cuts with minimal effort. This not only saves time but also reduces the risk of mistakes or inaccuracies that can slow down the overall workflow. Additionally, the smooth cutting action of the blade eliminates the need for extensive sanding or finishing, further saving time and effort.

Productivity

The use of a high-quality fine finish saw blade has significantly increased my productivity. With the ability to make precise cuts quickly and effortlessly, I am able to complete projects in a shorter timeframe. This not only allows me to take on more projects but also ensures that I can deliver results to my clients in a timely manner. The time saved from not having to spend excessive hours on sanding or finishing also allows me to take on additional work or focus on other aspects of the project, further enhancing my overall productivity.

In conclusion, by investing in the best fine finish saw blade, I have been able to increase my efficiency and productivity as a woodworker. The precision and speed at which the blade operates have allowed me to save time, avoid mistakes, and deliver high-quality results to my clients. Whether working on a small-scale project or a large-scale production, having the right saw blade is crucial in maximizing efficiency and productivity.

Reducing Chip-outs and Tear-outs

As a woodworking enthusiast, I understand the frustration that comes with chip-outs and tear-outs when working with a saw blade. These imperfections can ruin the quality of your work and leave you feeling unsatisfied.

Fortunately, there are ways to reduce chip-outs and tear-outs when using a fine finish saw blade. Firstly, choosing the right type of saw blade is crucial. Look for a blade with a high tooth count and a lower hook angle, as this will minimize the chances of chipping or tearing the wood fibers. Additionally, blades with carbide teeth tend to provide better results as they are more durable and less prone to dulling.

- Optimizing the cutting speed is another effective method to prevent chip-outs and tear-outs. By reducing the speed, you can maintain better control and accuracy, resulting in cleaner cuts.

- Applying masking tape or painter’s tape onto the surface of the wood before cutting can also help prevent the wood fibers from splintering. The tape acts as a protective layer, providing support and stability during the cutting process.

- Using a zero-clearance insert on your table saw can also make a significant difference in preventing chip-outs. This insert helps to support the wood fibers, resulting in a cleaner cut with minimal tear-out.

Remember that the type of wood you are working with can also impact the occurrence of chip-outs and tear-outs. Softer woods, such as pine, are generally more prone to these imperfections. Taking extra care and employing these techniques can greatly reduce the risk of chip-outs and tear-outs, leaving you with a high-quality, smooth finish on your woodworking projects.

Choosing the Right Tooth Geometry

As an experienced woodworker, I understand the importance of selecting the right fine finish saw blade for each project. One crucial factor to consider is the tooth geometry of the blade. Different tooth geometries are designed to cut specific materials and achieve different finishes, so choosing the right one is essential.

Flat-top grind (FTG) blades: These blades feature teeth with a squared-off top, giving them a flat shape. They are ideal for cutting through hardwoods and providing a clean, smooth finish. The FTG tooth geometry is well-suited for making rip cuts, where the blade cuts through the wood fibers in a straight line.

Alternate top bevel (ATB) blades: These blades have teeth with alternating angles, creating a crosscut or beveling effect. They are perfect for making precise crosscuts in materials like plywood and melamine. The ATB tooth geometry is also great for trimming and molding work, as it provides a clean, splinter-free finish.

Triple chip grind (TCG) blades: These blades have a combination of teeth with straight and beveled edges. They are specifically designed for cutting through hard materials, such as laminates and plastics. The TCG tooth geometry helps reduce chipping and provides a smooth, even finish.

When choosing the right tooth geometry for a fine finish saw blade, it’s essential to consider the material you’ll be working with and the finish you want to achieve. Taking these factors into account will help you select the perfect blade for your project and ensure that you achieve the best possible results.

Understanding Blade Coatings and Materials

When it comes to choosing the best fine finish saw blade, understanding blade coatings and materials is crucial. The right blade coating and material can greatly impact the performance and longevity of the saw blade, as well as the quality of the finish.

Blade Coatings:

Blade coatings are applied to the surface of the blade to enhance its performance and durability. There are several different types of blade coatings available, each with its own unique characteristics:

- Carbide-Tipped Coatings: Carbide-tipped coatings are made from a combination of carbide and other materials. These coatings are known for their wear resistance and ability to withstand high heat, making them ideal for cutting through tough materials like hardwood or metal.

- Titanium Nitride Coatings: Titanium nitride coatings provide improved hardness and heat resistance compared to standard carbide coatings. They help reduce friction and heat build-up during cutting, resulting in longer blade life and improved cutting performance.

- PVD Coatings: Physical vapor deposition (PVD) coatings offer excellent wear resistance, reducing the frequency of blade sharpening or replacement. These coatings also provide low friction and improved cutting speed.

Blade Materials:

The material used to make the blade itself also plays a significant role in its performance. Some common blade materials include:

- High-Speed Steel (HSS): HSS blades are known for their durability, heat resistance, and ability to maintain their cutting edge for extended periods. They are suitable for a wide range of cutting applications.

- Carbide-Tipped Blades: Carbide-tipped blades feature carbide teeth, which provide excellent cutting performance and longevity. These blades are ideal for cutting through abrasive materials like laminate or hardwood.

- Bi-Metal Blades: Bi-metal blades combine the durability of HSS blades with the cutting performance of carbide-tipped blades. They offer excellent versatility and can be used for both wood and metal cutting.

Conclusion:

When selecting the best fine finish saw blade, considering both the blade coating and material is essential. Different coatings provide different advantages in terms of wear resistance, heat resistance, and cutting performance. Similarly, various blade materials offer specific benefits such as durability and versatility. By understanding the options available and matching them to your specific cutting needs, you can ensure that you have the best blade for your fine finish projects.

10 Best Fine Finish Saw Blade

Features

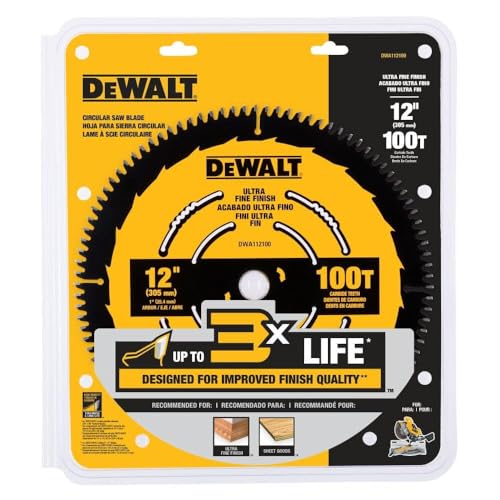

| Part Number | DWA112100 |

| Model | DWA112100 |

| Color | Black, Yellow |

| Size | One Size |

- Up to 3x Life* designed for improved finish quality**

- Patented Body Slot Design forLow Vibration

- Optimized Tooth Geometry Designed For Increased Accuracy

- Ultra Sharp Carbide For Clean Cutting

- Precision Tensioning For Added Stiffness To The Blade​

Features

| Part Number | D1280X |

| Model | D1280X |

| Warranty | Freud's Limited Lifetime Guarantee |

| Color | Multi |

| Size | 12" |

- Makes Clean Finish Cuts in Wood and Delicate Molding

- Produces Smooth, Quiet Cuts with Laser-Cut Kerf

- Features Shock-Resistant Carbide for Long-Lasting Precision

- Fine Finish

- Lifetime Guarantee

Features

| Part Number | LU88R010 |

| Model | LU88R010 |

| Warranty | Freud Limited Tooling Warranty. Contact Freud customer service for more details. 800-334-4494 |

| Color | Multi |

| Size | One Size |

- Specs: Arbor 5/8", Diameter 10", Grind ATB, Hook Angle 15°, Kerf .090", Plate .071", Teeth 60

- Premium TiCo HI-Density Carbide Crosscutting Blend for Maximum Performance

- Positive Hook Angles produce a smoother cut and allow for a faster feed rate

- Thin Kerf reduces waste and feeds easier

- Perma-Shield Non-Stick Coating reduces blade drag, protects the blade from corrosion and pitch build-up

Features

| Part Number | LU79R007 |

| Model | LU79R007 |

| Warranty | Freud Limited Tooling Warranty. Contact Freud customer service for more details. 800-334-4494 |

| Color | Multi |

| Size | One Size |

- Specs: Arbor 5/8", Diameter 7-1/4", Grind Hi-ATB, Hook Angle -5°, Kerf .079", Plate .063", Teeth 60

- Premium TiCo HI-Density Carbide Crosscutting Blend for Maximum Performance

- High Alternate Top Bevel (HiATB)Tooth Design produces splinter-free cuts

- Modified Triple Chip Grind (MTCG) Tooth Design for long life and chip free cuts in thick stock manmade materials

- Perma-Shield Non-Stick Coating reduces blade drag, protects the blade from corrosion and pitch build-up.

Features

| Part Number | FRE-D1280X |

| Model | LU88R012 |

| Warranty | Freud Limited Tooling Warranty. Contact Freud customer service for more details. 800-334-4494 |

| Color | Multi |

| Size | One Size |

- Specs: Arbor 1", Diameter 12", Grind ATB, Hook Angle 15°, Kerf .094", Plate .071", Teeth 80

- Premium TiCo HI-Density Carbide Crosscutting Blend for Maximum Performance

- Positive Hook Angles produce a smoother cut and allow for a faster feed rate

- Thin Kerf reduces waste and feeds easier

- Perma-Shield Non-Stick Coating reduces blade drag, protects the blade from corrosion and pitch build-up.

FAQ:

What is a fine finish saw blade?

A fine finish saw blade is a type of saw blade that is specifically designed to create smooth and clean cuts in materials such as wood, plastic, and metal. It is typically used for projects that require a high level of precision and a smooth, polished result.

What are the advantages of using a fine finish saw blade?

Using a fine finish saw blade offers several advantages. Firstly, it helps to create clean and precise cuts, resulting in a professional-looking finish. Secondly, it reduces the chances of splintering or chipping the material being cut. Finally, it can help to increase the overall efficiency and speed of the cutting process.

What are the different types of fine finish saw blades available?

There are several different types of fine finish saw blades available, depending on the material being cut. Some common types include high-speed steel blades, carbide-tipped blades, and diamond blades. Each type has its own advantages and is designed to produce the best results in specific materials.

What factors should I consider when choosing a fine finish saw blade?

When choosing a fine finish saw blade, there are several factors to consider. Firstly, you should consider the material you will be cutting and choose a blade that is specifically designed for that material. Secondly, you should consider the size and thickness of the blade, as well as the number of teeth, as these factors can affect the quality of the cut. Finally, you should consider the brand and reputation of the manufacturer, as well as any customer reviews or recommendations.

What are some popular brands of fine finish saw blades?

There are several popular brands of fine finish saw blades available on the market. Some well-known brands include Freud, Diablo, Bosch, and DeWalt. These brands are known for their quality and precision, and many professionals in the woodworking and construction industries trust these brands for their fine finish cuts.

Conclusion

In conclusion, when it comes to finding the best fine finish saw blade, there are several factors to consider. The material of the blade, the number of teeth, and the type of grind are all important considerations in achieving a smooth and precise finish. Whether you are working with wood, plastic, or other materials, choosing the right blade can make all the difference in the quality of your cuts. Furthermore, understanding the specific needs of your project will help guide you in selecting the appropriate fine finish saw blade. By taking these factors into account and doing proper research, you can ensure that you are investing in a high-quality blade that will deliver exceptional results.