Hello, my name is [Your Name] and I am a woodworking enthusiast. Today, I want to share with you my experience in finding the best saw to cut MDF board. MDF, or Medium Density Fiberboard, is a popular material for many woodworking projects due to its affordability and versatility.

When it comes to cutting MDF board, it’s important to choose the right saw that will provide clean and precise cuts. After trying out various saws, I have found that a circular saw with a carbide-tipped blade is the best option for this task.

A circular saw allows for straight and accurate cuts, which is crucial when working with MDF board. The carbide-tipped blade, on the other hand, ensures that the cuts are clean and free from splintering. This combination of a circular saw and a carbide-tipped blade makes the cutting process smooth and efficient.

Another advantage of using a circular saw for cutting MDF board is its versatility. With a circular saw, you can easily adjust the cutting depth to match the thickness of the MDF board. This allows you to make both shallow and deep cuts with ease.

In conclusion, after trying out various saws, I have found that a circular saw with a carbide-tipped blade is the best choice for cutting MDF board. Its ability to provide clean and precise cuts, along with its versatility, make it a must-have tool for any woodworking enthusiast. So, if you’re planning to work with MDF board, I highly recommend investing in a good circular saw.

Why choose the right saw for cutting MDF board

When it comes to cutting MDF board, it is crucial to choose the right saw for the task. The wrong saw can result in rough edges, splintering, and even damage to the board. This is why I always make sure to select the appropriate saw for cutting MDF board.

An ideal saw for cutting MDF board is one with a fine-toothed blade. The fine teeth help to minimize chipping and splintering, resulting in smoother cuts. Additionally, using a saw with a higher tooth count can also provide cleaner edges and reduce dust during the cutting process.

Furthermore, it is essential to consider the type of saw that will provide the most precise and accurate cuts for MDF board. A miter saw or a table saw with a sliding feature can be an excellent choice, as they allow for controlled cuts with adjustable angles. This is especially beneficial when working on projects that require precise measurements and angles.

Avoiding using a circular saw or a jigsaw can benefit the quality of the cuts on MDF board. These saws tend to produce more splintering and rougher edges, which may not be desirable for certain projects. However, if a circular saw or jigsaw is the only option available, using a blade specifically designed for cutting MDF can help improve the results.

Circular saw: the preferred tool for cutting MDF board

As a professional woodworker, I can confidently say that when it comes to cutting MDF board, a circular saw is the ideal tool for the job. While there are other options available, such as a table saw or a jigsaw, the circular saw offers the perfect balance of precision and versatility.

One of the main advantages of using a circular saw for cutting MDF board is its ability to make straight cuts with ease. The saw’s circular blade, specifically designed for cutting through various materials, including MDF, ensures clean and precise cuts every time. The adjustable cutting depth and angle options make it even more convenient to achieve the desired results.

Efficiency and Versatility

Another reason why a circular saw is the top choice for cutting MDF board is its efficiency and versatility. Unlike a table saw, which requires a dedicated work surface, a circular saw allows you to work on any surface, making it suitable for both small and large projects. Its handheld design also provides more control and maneuverability, allowing you to make curved cuts or navigate tight corners effortlessly.

Additionally, a circular saw can be equipped with various types of blades, depending on the specific cutting needs. For MDF board, a carbide-tipped blade is recommended as it offers long-lasting sharpness and durability. This versatility allows the circular saw to be used for a wide range of other woodworking tasks, making it a valuable addition to any DIYer or professional’s toolbox.

- Circular saw allows for straight and precise cuts in MDF board.

- Adjustable cutting depth and angle options for desired results.

- Efficient and versatile, suitable for projects of all sizes.

- Handheld design provides control and maneuverability.

- Can be equipped with different blades for various cutting needs.

Jigsaw: a versatile option for cutting MDF board

As someone who frequently works with MDF board, I have found the jigsaw to be an incredibly versatile tool for cutting this material. The jigsaw’s ability to make curved cuts, as well as straight cuts, makes it an excellent choice for working with MDF board, which often requires intricate shapes and designs.

I particularly appreciate the jigsaw’s maneuverability and ease of use. The lightweight and handheld nature of the tool allows me to have complete control and precision when cutting MDF board. Whether I need to cut a simple straight line or create a complex shape, the jigsaw’s adjustable blade speed and orbital action feature make it an ideal choice for achieving clean and accurate cuts.

Another advantage of using a jigsaw for cutting MDF board is the versatility of blade options. Depending on the specific cutting task, there are various blades available that can be easily interchanged. This allows me to choose a blade that is best suited for the thickness and density of the MDF board, ensuring optimal cutting performance and minimizing the risk of splintering or chipping.

In conclusion, the jigsaw is a highly recommended tool for cutting MDF board due to its versatility, maneuverability, and ease of use. Whether you are a professional carpenter or a DIY enthusiast, investing in a good quality jigsaw will undoubtedly enhance your ability to create precise and intricate cuts on MDF board.

Table saw: precision cutting for MDF board

When it comes to cutting MDF board, one of the best tools to use is a table saw. With its powerful motor and stable work surface, a table saw offers the precision and control necessary for making clean and accurate cuts in MDF board. As a woodworking enthusiast, I have found that using a table saw allows me to achieve professional-looking results with ease.

One of the key advantages of using a table saw to cut MDF board is its ability to make straight and smooth cuts. The large surface area of the table provides a stable platform for guiding the board through the blade, ensuring that the cuts are precise and even. The adjustable fence on the table saw also allows for consistent measurements, making it easier to cut multiple pieces of MDF board to the same size. Additionally, the powerful motor of a table saw ensures that the blade cuts through the dense MDF material effortlessly.

Another benefit of using a table saw is its versatility. With a variety of blade options available, you can choose the best one for cutting MDF board, such as a carbide-tipped blade specifically designed for cutting dense materials. The ability to adjust the blade height and angle also allows for bevel cuts and other intricate designs, giving you the freedom to create custom shapes and patterns in your MDF projects.

In conclusion, if you are looking for precision cutting for MDF board, a table saw is an excellent choice. Its stability, power, and versatility make it the perfect tool for achieving clean and accurate cuts in MDF board, whether you are working on a simple DIY project or a more complex woodworking endeavor.

Band saw: a specialized tool for cutting MDF board

When it comes to cutting medium-density fiberboard (MDF), a band saw is a must-have tool for any serious woodworker or DIY enthusiast. This specialized saw is designed to make precise and clean cuts in MDF, ensuring that your projects turn out professional and polished.

The band saw is ideal for cutting MDF because of its versatility and accuracy. Unlike other saws, such as a circular saw or jigsaw, the band saw uses a continuous band of teeth to cut through the material. This results in a smoother and cleaner cut, reducing the risk of chipping or splintering the MDF. The band saw also allows for greater control and maneuverability, making it easier to follow intricate patterns or curves.

Another advantage of using a band saw for cutting MDF is its adjustable blade speed. MDF is a dense material that requires a slower cutting speed to prevent overheating and burning. Many band saws have adjustable speed settings, allowing you to customize the blade speed to match the thickness and density of the MDF board.

Using a band saw to cut MDF requires proper safety precautions. Always wear protective goggles and gloves and ensure that the blade is properly set and tensioned before beginning. It is also important to secure the MDF board firmly in place to prevent any movement or slipping during the cutting process.

Safety Tips for Cutting MDF Board with a Saw

When working with MDF board and a saw, it is important to prioritize safety. Here are some essential tips to keep in mind:

- Wear Protective Gear: Always wear safety goggles to protect your eyes from flying debris. Additionally, use ear protection to prevent hearing damage from the noise generated by the saw.

- Choose the Right Saw Blade: Select a saw blade specifically designed for cutting MDF board. The blade should have a high number of teeth and a fine tooth configuration to minimize tear-out and produce clean cuts.

- Secure the MDF Board: Ensure that the MDF board is firmly clamped or secured before cutting. This will prevent the board from moving during the cutting process, reducing the risk of accidents.

- Set the Correct Cutting Depth: Adjust the cutting depth of the saw blade to slightly more than the thickness of the MDF board. This will prevent the blade from cutting into the work surface and causing damage.

- Take it Slow: Avoid rushing the cutting process. Instead, make smooth and steady cuts. Applying excessive force or working too quickly can lead to kickbacks or other accidents.

- Use a Guide: To ensure straight and accurate cuts, consider using a guide or a straight edge. This will help maintain the desired cutting line and prevent the saw from wandering off course.

- Mind Your Fingers: Always keep your fingers away from the path of the saw blade. Use a push stick or a push block to safely guide the MDF board through the saw.

- Work in a Well-Ventilated Area: Cutting MDF boards can generate fine dust particles. To minimize the inhalation of dust, work in a well-ventilated area or use dust collection systems and wear a respiratory mask.

- Clean Up Properly: Once you are finished cutting, clean the work area thoroughly. Remove any debris or sawdust from the work surface to prevent slips, trips, and falls.

Remember: Always prioritize safety when cutting MDF board with a saw. Following these tips will help ensure a safe and successful cutting experience.

10 Best Saw To Cut Mdf Board

Features

| Part Number | CC01H85119U10 |

| Model | CC01H85119U10 |

| Color | 12x19 |

| Size | 10 |

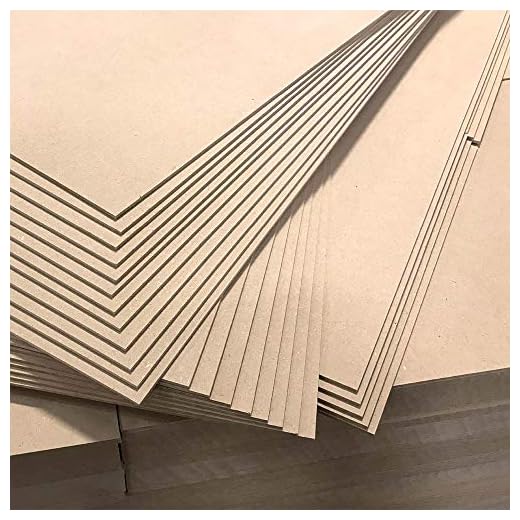

- Medium Density Fibreboard. MDF is more dense and stronger than particle board, and a more even consistency compared to plywood

- Stable Dimensions: Less expansion and contractions compared to natural wood.

- Takes paint and glue well with consistent appearance of finished project.

- Shapes well with CNC or laser

Features

| Part Number | MDF |

| Model | MDF BLANK |

| Warranty | Manufacture warranty for shipping issues. |

| Color | 1/8" |

| Size | 20 Pack |

- Perfect for your Glowforge, Make Block, X-tool and other laser machine

- MDF is renown for being more consistent that particle board and more stable than plywood

- Easy to machine with a router or laser.

- Great for arts and crafts

- More wood products search "Steve's Rack Shack" in the Amazon search bar.

Features

| Part Number | CC01H45119U10 |

| Model | CC01H45119U10 |

| Color | 12x19 |

| Size | 10 |

- Medium Density Fibreboard. MDF is more dense and stronger than particle board, and a more even consistency compared to plywood

- Stable Dimensions: Less expansion and contractions compared to natural wood.

- Takes paint and glue well with consistent appearance of finished project.

- Shapes well with CNC or laser

Features

| Part Number | MDF-1/4x12x24 |

| Model | MDF-1/4x12x24 |

| Color | Pack of 16 pieces |

| Size | 1/4" x 12 x 24 |

- NEW STOCK - LIGHT COLOR MDF

- SHIPPING INCLUDED

- PREMIUM MDF PANELS

- WHAT'S INCLUDED: You can purchase 16pcs, 32pcs, 48PCS or 64pcs. The actual sizes are 11-3/4" x 23-3/4". Shipping is included in the prices.

Features

| Part Number | DMP-18P |

| Model | BASSWOOD-12×24 |

| Warranty | 3 month return and exchange |

| Color | Basswood 18 pack |

| Size | 12"x24"x1/8" |

- 【Large Size】You will receive 18 pieces of light basswood sheets for crafts.each plywood sheets measures approx.300 x 600 mm/12 x 24 inches.and almost 3mm/1/8 inch in thickness.Sufficient quantity and large size can make your creations more diverse and colorful.

- 【Perfect Quality】This unfinished wood sheets are made of natural wood, lightweight, and has beautiful wood grain. Plywood sheets has the characteristics of smooth surface, no burrs, and completely straight. It is the ideal material for making DIY models for you.

- 【Easy to Use】Our basswood sheets 1/8 is suitable for beginners and experienced individuals. It is easy to use and can be processed using methods such as roller saws, laser cutting, laser engraving, regular utility knife, and wood burning. Painting and staining are also good choices.

- 【Wide Application】3mm basswoood sheet Board are great for various crafts projects,such as Architectural Model,pagoda bridge,mini house,wooden sailing, film props, military model, toys,making signs, place cards, coasters, ornaments, DIY patterns, alphabet game, photo props, wall decor wedding decorations, wood home decor, outdoor welcome signs and name puzzles and more.

- 【DIY Gifts】High quality thin plywood board make your creations full of fun. We can make gifts during various holidays, such as Children's Day, Valentine's Day, Halloween, Thanksgiving, Christmas, and more. It is also suitable for creating small gifts for gatherings, birthdays, weddings, anniversaries, and more.

FAQ:

What is the best saw to cut MDF board?

The best saw to cut MDF board is a circular saw with a fine-toothed blade. This type of saw can make smooth and precise cuts in the MDF board.

Can I use a jigsaw to cut MDF board?

Yes, you can use a jigsaw to cut MDF board. However, it is important to use a fine-toothed blade and go slowly to prevent splintering or chipping of the board.

Should I use a table saw or a hand saw to cut MDF board?

Both a table saw and a hand saw can be used to cut MDF board. A table saw is more stable and can make straight cuts easily, while a hand saw provides more control for curved or detailed cuts.

Conclusion

In conclusion, the best saw to cut MDF board is a table saw with a fine-toothed blade. This type of saw provides clean and precise cuts, resulting in smooth edges and minimal splintering. It is important to use a high-quality blade that is specifically designed for cutting MDF to reduce the risk of chipping or tearing the board. Additionally, proper safety precautions should be followed when using the table saw, including wearing protective goggles and gloves, and using a push stick to guide the board through the saw. With the right saw and technique, cutting MDF board can be a smooth and efficient process.