When it comes to cutting plexiglass, a circular saw can be a handy tool if used correctly. Plexiglass, also known as acrylic glass, is a popular material for various DIY projects and crafts due to its strength, transparency, and versatility. However, cutting it can be tricky as it tends to crack and chip easily if the wrong method is used.

To cut plexiglass with a circular saw, there are a few important steps to follow. First and foremost, it is crucial to select the right type of circular saw blade. A blade with fine teeth specifically designed for cutting plastic materials, such as acrylic and plexiglass, is recommended. This type of blade helps minimize chipping and produces clean, smooth cuts.

Before starting the cutting process, it is essential to measure and mark the cut line on the plexiglass. Using a ruler or a straightedge, draw a clear line to guide the saw. To prevent the plexiglass from cracking or splintering, it is advisable to apply masking tape along the marked line. The tape acts as a protective barrier and helps stabilize the glass during the cutting process.

Once the blade and the plexiglass are prepared, it is time to cut. It is crucial to maintain a slow and steady cutting speed to avoid overheating the material. Running the saw at high speeds can melt the plexiglass, leading to rough edges and potential damage. Additionally, applying light pressure when cutting is recommended to minimize the risk of cracking or chipping.

In conclusion, cutting plexiglass with a circular saw requires careful attention to detail and the right tools. By following the steps mentioned above and taking the necessary precautions, you can achieve precise and clean cuts in your plexiglass projects. Remember to always prioritize safety and wear appropriate protective gear, such as gloves and safety glasses, when working with power tools.

What is plexiglass?

Plexiglass, also known as acrylic glass, is a transparent and versatile plastic material that is commonly used as a lightweight alternative to glass. It is a polymer made from methyl methacrylate monomers, which are chemically linked together to form a solid structure.

Plexiglass is known for its durability, high impact resistance, and optical clarity. It is also resistant to weathering, UV radiation, and chemicals, making it suitable for both indoor and outdoor applications. Plexiglass can be easily molded, shaped, and fabricated into various forms, such as sheets, tubes, rods, and profiles.

Due to its transparency and versatility, plexiglass is widely used in industries such as architecture, automotive, signage, lighting, displays, and furniture. It is often used in windows, skylights, protective barriers, shelves, display cases, and art installations.

| Advantages of Plexiglass |

|---|

| 1. Lightweight |

| 2. Shatter-resistant |

| 3. High optical clarity |

| 4. UV resistance |

| 5. Chemical resistance |

| 6. Easy to fabricate |

Overall, plexiglass is a versatile material that offers numerous advantages over traditional glass, making it a popular choice for various applications. However, when working with plexiglass, it is important to use the correct tools and techniques to ensure clean cuts and prevent cracking or chipping.

Why use a circular saw?

A circular saw is a versatile and powerful tool that is commonly used for cutting a variety of materials, including plexiglass. Here are some reasons why you might choose to use a circular saw for cutting plexiglass:

- Efficiency: A circular saw is designed to quickly and accurately cut through materials. It can make both straight cuts and curved cuts, making it a versatile tool for various cutting tasks.

- Precision: The circular saw’s blade is sharp and can be adjusted to cut plexiglass with precision. This allows for a clean and accurate cut, ensuring that your finished project looks professional.

- Speed: Using a circular saw can save you time compared to other cutting methods. The saw’s powerful motor and fast blade rotation speed enable it to cut through plexiglass quickly and efficiently.

- Control: Circular saws are typically designed with ergonomic handles that provide a comfortable grip, allowing you to maintain control while cutting. This results in greater accuracy and reduces the risk of accidents.

- Versatility: In addition to cutting plexiglass, a circular saw can be used for various other cutting tasks, such as cutting wood, metal, and plastic. This makes it a valuable tool to have in your workshop.

When using a circular saw to cut plexiglass, it is important to take proper safety precautions, such as wearing safety goggles and gloves, using clamps to secure the material, and following the manufacturer’s instructions. By using a circular saw, you can achieve precise and efficient cuts in your plexiglass projects.

Important Safety Measures

When cutting plexiglass with a circular saw, it is crucial to prioritize safety to prevent accidents and injuries. Keep in mind the following safety measures:

Wear Protective Gear

Before starting any cutting operation, ensure that you are wearing the appropriate protective gear. This includes safety goggles to protect your eyes from flying debris, a face shield to guard against larger fragments, and gloves to protect your hands.

Choose the Right Blade

Using the correct blade is essential for cutting plexiglass. Select a fine-toothed carbide-tipped saw blade designed specifically for cutting acrylic materials. This type of blade will minimize chipping and provide cleaner cuts.

Note: Never use a regular wood-cutting blade as it may cause excessive heat and cracking.

Expert Tip: Apply a layer of masking tape on both sides of the plexiglass before cutting. This will help reduce chipping.

Secure the Plexiglass

Make sure the plexiglass is securely clamped to a stable surface before beginning the cutting process. This will prevent the material from moving or vibrating during the cut, reducing the risk of accidents and ensuring accurate results.

Slow and Steady Cutting

When cutting plexiglass, it is important to maintain a slow and steady cutting speed. This will help prevent the blade from binding or overheating, leading to smoother and cleaner cuts. Avoid forcing the saw through the material, instead, let the blade do the work.

Expert Tip: Applying a lubricant like water or cutting oil to the blade can help reduce heat and friction, resulting in cleaner cuts.

Proper Dust and Debris Control

Always work in a well-ventilated area to prevent the accumulation of dust and debris. Plexiglass particles can become airborne and potentially irritate your respiratory system or eyes. Consider using a dust collector or wearing a respiratory mask to minimize exposure.

Remember: Be cautious when working with power tools, follow these safety measures, and always read and follow the manufacturer’s instructions for both the circular saw and the plexiglass you are cutting.

Step-by-step process of cutting plexiglass with a circular saw

Cutting plexiglass can be a tricky task, but with the right tools and technique, it can be done effectively. One tool that can be used for this purpose is a circular saw. Here is a step-by-step guide on how to cut plexiglass using a circular saw.

Step 1: Gather the necessary materials

Before starting the cutting process, make sure you have all the necessary materials. You will need a circular saw with a fine-tooth, carbide-tipped blade, a tape measure, a straight edge, clamps, and safety equipment such as gloves and goggles.

Step 2: Measure and mark the plexiglass

Using a tape measure, measure the dimensions of the plexiglass sheet you need to cut. Mark the measurements on the protective film of the plexiglass using a marker or a score. Make sure the marks are clear and visible.

Step 3: Set up the circular saw

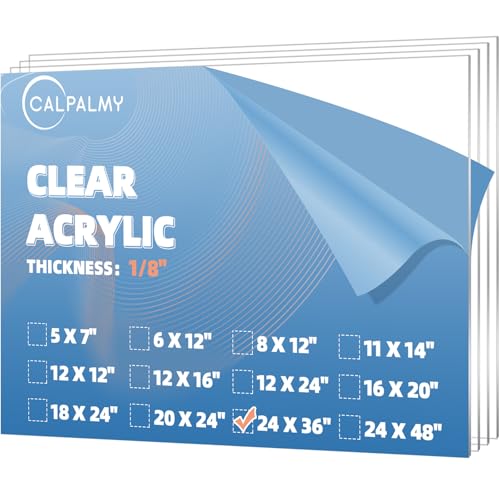

Attach the fine-tooth, carbide-tipped blade to your circular saw. Adjust the cutting depth of the saw according to the thickness of the plexiglass. It is recommended to set the cutting depth slightly deeper than the thickness of the plexiglass to prevent chipping.

Step 4: Clamp the plexiglass

In order to prevent the plexiglass from moving during the cutting process, secure it in place using clamps. Make sure the clamps are positioned away from the path of the saw blade.

Step 5: Start cutting

Position the saw blade just outside the marked line. Turn on the circular saw and slowly guide it along the marked line, letting the saw do the cutting. Apply a gentle downward pressure to prevent the plexiglass from vibrating or cracking.

Step 6: Finish the cut

Continue cutting along the marked line until you reach the end. Take your time and do not rush the process. Once the cut is complete, turn off the circular saw and let it come to a complete stop before moving the plexiglass.

Important tip: To reduce the risk of chipping or cracking, you can apply masking tape along the marked line before cutting.

In conclusion, cutting plexiglass with a circular saw requires precision and care. By following the step-by-step process outlined above, you can achieve clean and accurate cuts on your plexiglass sheet.