If you have an old table saw that has seen better days, it’s time to give it a new lease on life. Cleaning up and restoring an old table saw not only improves its appearance, but also ensures its optimal performance and longevity. This guide will walk you through the steps to effectively clean your old table saw and get it back in working order.

Step 1: Safety First

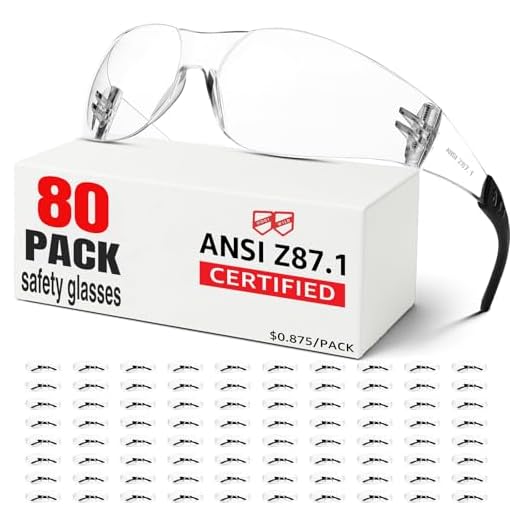

Before you start the cleaning process, it’s important to prioritize safety. Make sure your table saw is unplugged and completely turned off. Wear protective gloves and eye goggles to safeguard yourself from any potential injuries during the cleaning process.

Step 2: Remove Dust and Debris

Begin by removing any loose dust and debris from the surface of the table saw. Use a soft brush or a vacuum cleaner with a brush attachment to gently remove the dirt. Be thorough and pay attention to hard-to-reach areas, such as under the blade and in the corners.

Step 3: Clean the Table Surface

Next, clean the table surface of the saw. Use a mild cleaning solution or a mixture of warm water and dish soap. Dampen a clean cloth or sponge with the solution and gently scrub the table surface. Rinse with clean water and wipe dry with a soft, lint-free cloth.

Remember, it’s important to avoid using abrasive cleaners or rough materials that may scratch or damage the surface of the table saw.

Step 4: Lubricate Moving Parts

Once the table surface is clean and dry, it’s time to lubricate the moving parts of the table saw. Apply a small amount of lubricating oil to the pivot points, gears, and other moving components. Move the parts back and forth to distribute the oil evenly and ensure smooth operation.

Step 5: Inspect and Tighten

After cleaning and lubricating, take the time to inspect the table saw for any loose or worn parts. Tighten any loose screws, bolts, or nuts and replace any damaged components as necessary. This will help in improving the overall stability and safety of your table saw.

By following these steps and giving your old table saw some much-needed TLC, you can restore it to its former glory and enjoy it for many more years to come.

Gather Necessary Cleaning Supplies

Before you begin cleaning your old table saw, it’s important to gather all the necessary supplies. Having them on hand will save you time and make the cleaning process more effective.

Here’s a list of essential supplies you will need:

- Protective gloves

- Eye goggles

- Dust mask

- Cleaning solution (such as mild dish soap or a degreaser)

- Soft-bristle brush or toothbrush

- Clean rags or paper towels

- Bucket or container for cleaning solution

- Old toothpicks or cotton swabs for hard-to-reach places

- Lubricating oil or silicone spray

Make sure you have all these supplies ready before you start cleaning. This will ensure that you can clean your old table saw thoroughly and efficiently.

Clear the Work Area

Before you start cleaning your old table saw, it’s important to clear the work area and create a clean and organized space.

Begin by removing any items or debris from the table saw and the surrounding area. This includes tools, sawdust, and other materials that may have accumulated over time. Use a broom or vacuum to thoroughly clean the floor and workbench.

Next, assess the overall layout of your work area. Make sure there is enough space to comfortably maneuver around the table saw and access all its components. Remove any unnecessary items or equipment that may obstruct your movement or compromise safety.

If you have any materials or projects in progress, store them in a safe place away from the table saw. This will prevent them from getting damaged or interfering with your cleaning process.

Consider organizing your work area by implementing storage solutions such as shelves or tool racks. This will help keep your tools and supplies organized and easily accessible, making your future work on the table saw more efficient.

Remember to keep safety in mind at all times when clearing the work area. Wear appropriate protective gear, such as gloves and safety glasses, and be cautious of any sharp objects or potential hazards.

By clearing the work area before cleaning your old table saw, you will create a safer and more productive environment for your woodworking projects.

Disassemble the Table Saw

Before you can thoroughly clean an old table saw, you will need to disassemble it to access all the different parts and components. Here is a step-by-step guide on how to disassemble a table saw:

1. Unplug the table saw: To ensure your safety, always start by disconnecting the saw from its power source.

2. Remove the blade and the blade guard: Use the appropriate wrench to loosen and remove the bolt that holds the blade in place. Once the blade is removed, take off the blade guard as well.

3. Take off the throat plate: The throat plate is the small metal or plastic plate that covers the opening in the table saw where the blade comes through. Slide it out or unscrew it depending on the type of table saw you have.

4. Detach the fence and miter gauge: Most table saws have a fence attached to guide the wood during cuts. Loosen any knobs or screws that hold the fence in place and remove it. Additionally, remove the miter gauge if your table saw has one.

5. Remove the table top: Depending on the design of your table saw, you may need to remove the table top to access the inner components. Check the manual or look for any screws or bolts that are securing the table top to the base. Use the appropriate tool to remove them and set the table top aside.

6. Disassemble the motor housing: The motor housing is usually located at the back of the table saw. Depending on the model, you may need to remove screws or clips to access the motor and other components for cleaning.

7. Take apart any additional components: Some older table saw models may have additional components like gears, belts, or pulleys. If necessary, follow the manual or inspect the saw to identify any parts that need to be disassembled for cleaning.

8. Label and organize: As you disassemble the table saw, label each part or component to avoid confusion during reassembly. Keep all the screws, bolts, and small parts in separate containers or bags for easy organization.

By disassembling your old table saw, you will have better access to each part and component, making it easier to clean and maintain. Just remember to be cautious and follow the manufacturer’s guidelines to ensure a safe and successful disassembly process.

Clean and Lubricate the Parts

Once you have disassembled the table saw, it’s important to thoroughly clean each individual part. Use a brush or rag to remove any dust, dirt, or debris that may have accumulated over time. Pay special attention to the blade, fence, and miter gauge, as these are the parts that often get the dirtiest.

After cleaning the parts, it’s crucial to lubricate them to ensure smooth operation. Apply a few drops of lubricating oil to any moving or rotating parts, such as the gears, bearings, and pivot points. Be sure to use a lubricant that is specifically designed for power tools.

If any of the parts are rusted or corroded, you may need to use a rust remover or abrasive pad to remove the rust. After removing the rust, apply a rust inhibitor to prevent future corrosion.

Once all the parts have been cleaned and lubricated, reassemble the table saw and test its functionality. If there are any parts that are damaged or worn beyond repair, consider replacing them to ensure the saw’s safety and efficiency.

To keep your table saw in good condition, it’s recommended to clean and lubricate the parts regularly, at least once a year or more frequently if you use the saw frequently. Regular maintenance will not only prolong the life of your table saw but also ensure that it operates at its best performance.

Remove Rust and Corrosion

If your old table saw has rust and corrosion, it is important to remove it before cleaning and restoring the tool. Rust and corrosion can affect the functionality and accuracy of the saw, so proper removal is necessary.

Materials Needed:

- Steel wool or wire brush

- Vinegar or lemon juice

- Rust remover solution

- Protective gloves

- Protective eyewear

Steps to Remove Rust and Corrosion:

- Put on protective gloves and eyewear to ensure your safety.

- Use steel wool or a wire brush to gently scrub the affected areas of the table saw. Be sure to remove any loose rust or corrosion.

- If the rust is stubborn, you can soak a cloth in vinegar or lemon juice and apply it to the rusted areas. Let it sit for a few minutes to allow the acid to penetrate the rust.

- Afterward, scrub the rusted areas again with the steel wool or wire brush. The acid will help in loosening the rust, making it easier to remove.

- If the rust is still present, you may need to use a specialized rust remover solution. Follow the instructions provided with the product for the best results.

- Once you have removed the rust and corrosion, use a clean cloth to wipe away any residue.

- Inspect the table saw for any remaining rust or corrosion. Repeat the process if necessary.

Removing rust and corrosion from an old table saw is a crucial step in restoring its functionality and extending its lifespan. Take the time to remove rust properly before moving on to the cleaning and restoration process.

Reassemble and Test the Table Saw

Once you have thoroughly cleaned all the parts of your old table saw, it’s time to reassemble it. Start by carefully placing the cleaned blade back onto the arbor, making sure it is properly aligned. Use the wrench to tighten the blade securely, but be careful not to overtighten it.

Next, reconnect the motor to the base of the table saw using the screws or bolts provided. Make sure each screw or bolt is tightened securely. Check the power cord for any damage and plug it into a power outlet.

Before you test your reassembled table saw, it’s important to check the safety features. Ensure the blade guard is properly installed and functioning correctly. Double-check that the anti-kickback pawls are securely attached and working as intended.

To test the table saw, turn on the power switch and let the motor run for a few seconds. Listen for any unusual noises or vibrations. Inspect the blade to ensure it is spinning freely and not wobbling. Adjust the tension of the blade if necessary.

Once you are satisfied that everything is in working order, it’s time to make a test cut. Choose a scrap piece of wood and slowly push it through the blade. Pay attention to the cut quality and ensure the saw is cutting accurately and smoothly. Make any necessary adjustments to the blade or fence as needed.

Remember to always wear appropriate safety gear, such as safety glasses and hearing protection, when operating a table saw. Follow all safety guidelines and instructions provided by the manufacturer.

By following these steps, you can successfully reassemble and test your old table saw, bringing it back to its optimal working condition.