Whether you’re a professional carpenter or a DIY enthusiast, knowing how to cut a straight line with a reciprocating saw is a valuable skill to have. With its powerful motor and versatile blade, a reciprocating saw can make quick work of various cutting tasks. However, maintaining control and accuracy can be a challenge, especially when cutting long, straight lines.

In this article, we will guide you through the steps to ensure that your cuts are precise and straight every time.

1. Choose the right blade:

Before you start cutting, it’s important to select the right blade for the job. Different materials require different blades, so make sure you choose the one that is specifically designed for the material you are cutting. A fine-toothed blade is ideal for cutting straight lines in wood, while a coarser blade may be better for cutting through metal or plastic.

2. Mark your cutting line:

Using a pencil or a marker, mark a straight line along the surface you plan to cut. This will serve as your guide and help you maintain a straight path while cutting. To ensure accuracy, use a ruler or a straightedge to create a precise line.

3. Secure your workpiece:

Before you begin cutting, make sure your workpiece is firmly secured in place. Clamp it down to a workbench or use clamps to hold it securely. This will prevent the material from shifting or slipping, allowing you to make clean and straight cuts.

4. Use two hands to control the saw:

When operating a reciprocating saw, it’s important to have a solid grip and full control over the tool. Use both hands to hold the saw, with one hand on the handle and the other hand supporting the front of the saw. This will give you better stability and control, reducing the risk of the saw veering off course.

5. Start slowly and let the saw do the work:

Begin your cut by gently lowering the blade onto the material, starting at the edge of your marked cutting line. Start with a slow and steady motion, allowing the saw’s powerful motor to do the work. Let the blade move through the material at its own pace, exerting minimal force from your end. This will help maintain control and ensure a straight cut.

By following these steps and practicing your technique, you’ll be able to confidently cut straight lines with a reciprocating saw, making your woodworking projects look professional and precise.

What is a reciprocating saw?

A reciprocating saw, also known as a saber saw or a recip saw, is a versatile cutting tool commonly used in construction, demolition, and renovation projects. It operates by using a push-and-pull reciprocating motion, which allows the user to cut through a wide range of materials, including wood, metal, plastic, and even masonry.

The reciprocating saw consists of a motor, a blade, and a handle or grip. The motor drives the blade back and forth in a linear motion, which enables it to rapidly and efficiently cut through different materials. The blade itself is long, straight, and serrated, allowing it to bite into the material and create a clean, straight cut.

Key features of a reciprocating saw:

- Versatility: As mentioned earlier, a reciprocating saw can cut through a wide variety of materials, making it a valuable tool for various tasks.

- Portability: Reciprocating saws are typically lightweight and compact, allowing for easy maneuverability and operation in tight spaces.

- Blade options: There are different types of blades available for reciprocating saws, each designed for specific cutting tasks. Some blades are optimized for cutting wood, while others are better suited for metal or masonry.

- Variable speed control: Many reciprocating saws come with adjustable speed settings, allowing the user to customize the cutting speed based on the material and the desired result.

- Quick blade-changing system: Some models of reciprocating saws feature a tool-less blade changing mechanism, which makes it easy and fast to replace blades as needed.

Overall, a reciprocating saw is a powerful and versatile tool that can make quick work of cutting tasks in various construction and renovation projects. Its ability to cut a straight line, coupled with its portability and adaptability, makes it a valuable addition to any DIY or professional toolbox.

Importance of cutting a straight line

When using a reciprocating saw, it is crucial to be able to cut a straight line. Cutting in a straight line ensures precision and accuracy in your cuts, resulting in a professional-looking finish.

Here are some reasons why cutting a straight line is important:

- Professional appearance: A straight cut enhances the overall appearance of your work. Whether you are cutting through wood, metal, or plastic, a clean and straight line adds a polished and professional touch.

- Efficiency: Cutting along a straight line allows you to work more efficiently. It helps you save time and effort by avoiding unnecessary modifications and adjustments.

- Fits perfectly: A straight cut ensures that the pieces fit together seamlessly. This is especially important when you are working on projects such as building furniture or installing cabinets where precision is key.

- Safety: Cutting along a straight line reduces the risk of accidents and injuries. By maintaining control over the saw and following a straight path, you minimize the chances of the saw slipping or creating unexpected movements.

Overall, cutting a straight line is an essential skill that every DIY enthusiast or professional should possess. It not only improves the quality of your work but also enhances your efficiency and safety while using a reciprocating saw.

Step 1: Choose the right blade

When using a reciprocating saw, it is important to choose the right blade for the material you are cutting. The blade you use will determine the quality of the cut, as well as the speed and efficiency of your work. Here are some factors to consider when selecting the right blade:

Material:

Different blades are designed for cutting different materials, such as wood, metal, or plastic. Make sure to select a blade that is specifically designed for the material you are cutting. Using the wrong blade could result in a poor quality cut and may even damage the blade.

Tooth per Inch (TPI):

The number of teeth per inch on the blade determines the aggressiveness and speed of the cut. For rough, fast cuts, a blade with a lower TPI is appropriate. On the other hand, for smooth, precise cuts, a blade with a higher TPI is recommended.

Tip: If you are unsure about the right blade to use, consult the manufacturer’s recommendations or ask for advice at your local hardware store.

Blade types for cutting a straight line

When it comes to cutting a straight line with a reciprocating saw, choosing the right blade is crucial. The blade type you select can greatly affect the precision and quality of your cut. Here are a few blade types that are commonly used for cutting a straight line:

1. Finishing Blades

Finishing blades are designed with fine teeth and a narrow kerf, making them ideal for making precise and smooth cuts. These blades are commonly used for cutting materials like wood, plastic, and drywall. Their fine teeth allow for cleaner cuts with minimal tear-out, ensuring a professional-looking finish.

2. Demolition Blades

Demolition blades are more rugged and feature larger teeth and a wider kerf compared to finishing blades. These blades are specifically designed for cutting through tough materials such as metal, nails, and even masonry. Their aggressive cutting action allows for faster cutting speeds, making them suitable for heavy-duty tasks.

When cutting a straight line, it is essential to choose a blade that matches the material you are working with. Using the wrong blade can result in a crooked cut or damage to both the material and the reciprocating saw.

Remember to always wear appropriate safety gear, such as safety glasses and gloves, when operating a reciprocating saw. Take your time and make confident, steady motions to ensure a straight and clean cut. Practice on scrap materials before making precise cuts on your desired workpiece to gain better control and confidence.

Disclaimer: Always refer to the manufacturer’s instructions and safety guidelines when using power tools.

Step 2: Mark the line

Once you have selected the area where you want to make a straight cut, it is important to mark the line accurately. This will serve as a guide to ensure that you maintain a straight cut throughout the process.

To mark the line, you can use a measuring tape and a pencil. Measure the desired distance from the edge of the material and make a small mark. Repeat this process at multiple points along the line to create reference points.

If you are cutting a straight line along an existing edge, such as a board or a piece of plywood, you can simply place the saw blade against the edge and use it as a guide. However, if you are cutting a straight line in the middle of a sheet of material, you will need to mark the line from edge to edge.

Using a straightedge

If you want to ensure an even more accurate and straight cut, you can use a straightedge as a guide. Place the straightedge along the line you have marked and secure it in place using clamps or weights. This will provide you with a solid guide for the reciprocating saw, allowing you to make a precise cut.

Double-checking your line

Before making any cuts, it is always a good idea to double-check your line to ensure its accuracy. This can be done by measuring the distance of the line from both edges of the material and comparing the two measurements. Additionally, you can use a square or a level to check if the line is perfectly perpendicular to the edges.

Tools for marking a straight line

Before cutting a straight line with a reciprocating saw, it is important to properly mark the line to ensure accuracy and precision. There are a few tools that can be helpful in accomplishing this task:

Tape measure

A tape measure is a basic but essential tool for marking a straight line. It allows you to measure the desired length and mark it accurately on the material to be cut.

Straightedge or square

A straightedge or square is a tool that provides a straight reference line. It can be used to ensure that the line is perpendicular or parallel to the edge of the material. Place the straightedge or square along the measured line and use a pencil or marker to mark the line along the edge of the tool.

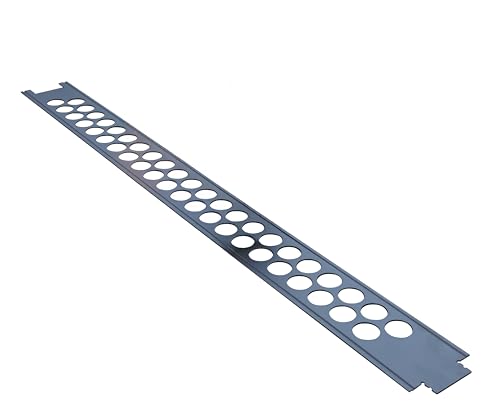

| Image | Description |

|---|---|

|

A tape measure is a flexible ruler used for measuring. |

|

A straightedge or square provides a straight reference line. |

Using these tools will help ensure that the line is straight and accurately marked for cutting with a reciprocating saw. It is important to take the time to measure and mark the line properly to avoid any mistakes or inaccuracies during the cutting process.