A table saw fence guide is an essential tool for any woodworker or DIY enthusiast. It helps to ensure accurate and precise cuts when using a table saw, which is crucial for achieving professional-looking results. Making your own table saw fence guide can be a cost-effective and rewarding project that will improve the functionality of your table saw.

There are several materials and methods you can use to create a table saw fence guide, depending on your needs and the resources available to you. One common approach is to use a piece of plywood or MDF as the main body of the fence guide. This can be easily cut to the desired length and width, and then secured to the table saw with clamps or screws.

Another important component of the table saw fence guide is the measuring system. This can be achieved by attaching a ruler or measuring tape along the length of the fence guide. Alternatively, you can use a self-adhesive measuring tape specifically designed for table saws.

It’s crucial to ensure that your table saw fence guide is straight, level, and securely fastened to the table saw. This can be achieved by using a combination of clamps, screws, and leveling tools. Once your fence guide is properly installed, you can make accurate and repeatable cuts with confidence.

By making your own table saw fence guide, you have the opportunity to customize it to your specific needs and preferences. You can choose the materials, measurements, and additional features that will best suit your woodworking projects.

In conclusion, a table saw fence guide is an essential tool for achieving accurate and precise cuts. Making your own fence guide allows you to customize it to your specific needs and improve the functionality of your table saw. Follow the steps outlined in this guide to create your own table saw fence guide and take your woodworking projects to the next level.

The importance of a table saw fence guide

A table saw fence guide is an essential component of any table saw setup. It helps to ensure accurate and consistent cuts, improving both the quality and safety of your woodworking projects.

Accurate Cuts

A table saw fence guide acts as a reliable reference point for your workpiece, allowing you to make precise measurements and cuts. With a properly aligned fence guide, you can easily set the desired width of your cut and trust that the saw blade will follow the intended path.

Without a fence guide, it can be challenging to maintain a consistent distance between the blade and the edge of the workpiece. This inconsistency can lead to uneven cuts, resulting in gaps or inaccuracies in your project.

Enhanced Safety

In addition to improving accuracy, a fence guide also enhances safety while using a table saw. By keeping the workpiece firmly against the fence, it reduces the likelihood of kickbacks or the workpiece binding against the blade.

Kickbacks can occur when a workpiece is not properly supported and gets caught in the spinning blade. This can be dangerous and may result in serious injury. A fence guide helps to prevent kickbacks by providing a stable surface for the workpiece and ensuring it remains in a secure position throughout the cut.

Furthermore, a fence guide helps to keep your hands and fingers at a safe distance from the blade, reducing the risk of accidental contact and potential injuries.

Overall, a table saw fence guide is an indispensable tool for any woodworker. It enables accurate and consistent cuts, improving the quality of your projects, while also enhancing safety by reducing the risk of kickbacks and accidental contact with the blade. Investing in a high-quality fence guide is a worthwhile step to ensure both precision and safety in your woodworking endeavors.

Section 1: Gathering materials

Before you start building your table saw fence guide, it’s important to gather all the necessary materials. Having everything prepared in advance will make the construction process much smoother. Here are the materials you will need:

- Measuring tape: This tool will ensure accurate measurements throughout the construction process.

- Ruler or straightedge: A ruler or straightedge will be needed to mark and guide your cuts.

- Plywood: You will need a sturdy piece of plywood that is at least 1/2 inch thick to construct the fence guide.

- Wood screws: Make sure to have a variety of wood screws on hand in different lengths to secure the fence components together.

- Drill: A power drill is essential for drilling pilot holes and driving screws.

- Saw: Depending on the design, you may need a circular saw or jigsaw to cut the plywood to size.

- Sandpaper or sanding block: Sandpaper or a sanding block will be necessary to smooth any rough edges and ensure a clean finish.

- Safety equipment: Don’t forget to wear safety goggles and gloves to protect your eyes and hands during the construction process.

By gathering all these materials, you will have everything you need to begin building your table saw fence guide. Having the right tools and equipment on hand will help you achieve better results and ensure the project goes smoothly.

Essential materials for a table saw fence guide

When it comes to making a table saw fence guide, having the right materials is crucial for ensuring accuracy and safety. Here are some essential materials that you will need:

| Material | Description |

|---|---|

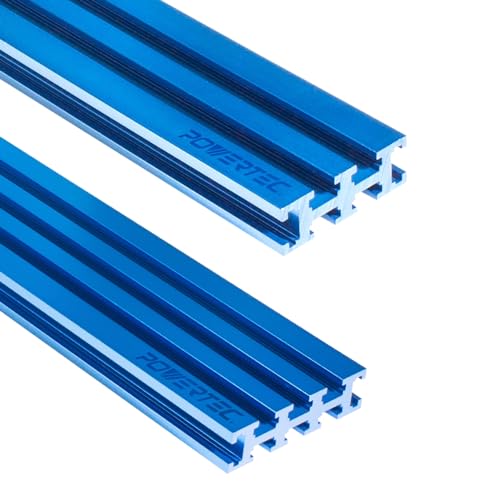

| Aluminum extrusion | An aluminum extrusion is a sturdy and lightweight material that will serve as the main body of your fence guide. It provides the necessary strength and rigidity for accurate cuts. |

| T-track | A T-track is a type of channel that is embedded into the aluminum extrusion. It allows for the attachment of various accessories such as stop blocks and featherboards. Look for a T-track that is compatible with your aluminum extrusion. |

| Fence material | The fence material is what will be in direct contact with your workpiece. It is usually made of solid wood or plywood and should be straight and smooth. This will ensure that your cuts are both accurate and clean. |

| Bolts and nuts | You will need bolts and nuts to attach the T-track to the aluminum extrusion, as well as the fence material to the T-track. Make sure to choose the appropriate size and length for your specific needs. |

| Measuring tape | A measuring tape is an essential tool for ensuring precise and consistent measurements throughout the construction process. Choose a tape with clear and easy-to-read markings. |

| Level | Using a level will help you ensure that your fence guide is perfectly parallel to the saw blade. This will prevent any accidental angling of the blade during cuts. |

| Screws | Screws will be used to secure the fence material to the T-track. Make sure to use screws that are appropriate for the thickness of your fence material. |

By having these essential materials on hand, you will be well-equipped to create a table saw fence guide that is both accurate and safe to use. Remember to carefully follow any additional instructions or safety precautions provided by the manufacturers of your specific materials.

Section 2: Measuring and cutting

Accurate measurements are crucial when making a table saw fence guide. The first step is to measure the width of the table saw blade. This will help determine the size of the fence guide needed to provide proper support and guidance for the wood being cut.

Using a measuring tape or ruler, measure the exact distance between the widest points of the saw blade. Take note of this measurement as it will be used to ensure the fence guide is the correct width.

Next, measure the desired length of the fence guide. Consider the size of the materials you typically work with and any specific needs for your projects. Make sure to take into account any allowance needed for the blade to protrude through the material being cut.

Once the measurements are determined, mark the dimensions on the material that will be used for the fence guide. A pencil or marker can be used to make these marks, but it’s important to use a tool that will not easily smudge or fade during the cutting process.

After marking the dimensions, use a square or straight edge to draw straight lines along the marked measurements. This will ensure that the cuts are straight and precise.

Now it’s time to make the cuts. Use a table saw or a circular saw with a guide to cut along the marked lines. Take your time and make sure to follow the lines accurately.

Once the cuts are complete, double-check the dimensions of the fence guide to ensure it matches the measurements you originally took. If adjustments need to be made, use sandpaper or a file to carefully adjust the size of the fence guide to fit the desired dimensions.

With the fence guide properly measured and cut, it is now ready to be installed onto the table saw. Ensure that it is securely fastened and aligned with the table saw blade, providing a reliable and accurate guide for future woodworking projects.

Measuring and cutting the fence guide components

To start building your table saw fence guide, you will first need to measure and cut the necessary components. This step is crucial to ensure accurate and precise results.

Here are the steps to follow:

Step 1: Measure the required length

Begin by measuring the length of your table saw’s surface where you plan to attach the fence guide. Use a measuring tape to get an accurate measurement. Make sure to account for any existing attachments or obstructions on the surface.

Step 2: Mark the measurements on your guide

Transfer the measurements onto the guide material that you have chosen. You can use a pencil to mark the measurements on both ends of the guide material.

Step 3: Cut the guide material

Secure the guide material onto a workbench or sawhorses. Use a circular saw or a table saw to cut the material according to the marked measurements. Make sure to follow all safety precautions when using power tools.

Step 4: Repeat the process if necessary

If you need multiple guide components, repeat steps 1 to 3 to measure and cut them accordingly. Ensure that all the components are of the same length for a precise and consistent fence guide.

Once you have finished measuring and cutting the fence guide components, you will be ready to assemble and attach them to your table saw. This custom fence guide will enhance the accuracy and safety of your woodworking projects.

Section 3: Assembly

Once you have gathered all the necessary materials and measurements, it’s time to start assembling your table saw fence guide. Follow these step-by-step instructions to ensure a smooth and successful assembly process:

Step 1: Prepare the Base

Begin by positioning the base of the fence guide on the tabletop of your table saw. Make sure it is centered and aligned properly, using a measuring tape and square if necessary. Once you are satisfied with the placement, mark the location of the screw holes on the tabletop.

Step 2: Attach the Base

Drill pilot holes at the marked locations on the tabletop, using a drill bit that matches the size of the screws you are using. Then, attach the base of the fence guide to the tabletop using the screws. Make sure the base is securely fastened and level with the tabletop.

Step 3: Install the Guide Rail

Next, position the guide rail on the base of the fence guide. Align it so that it runs parallel to the blade of your table saw. Use a square and measuring tape to ensure accurate alignment. Once you are satisfied with the position, mark the locations of the screw holes on the base.

Drill pilot holes at the marked locations on the base, using a drill bit that matches the size of the screws you are using. Then, attach the guide rail to the base using the screws. Ensure that the guide rail is securely fastened and level with the base.

Step 4: Attach the Fence

Finally, attach the fence to the guide rail. Slide it onto the guide rail, making sure it moves smoothly and locks into place securely. Use the adjustment knobs or screws on the fence to fine-tune the alignment as needed.

Once you have completed these steps, your table saw fence guide is assembled and ready to use. Make sure to double-check all the connections and alignments before using the fence guide for any cutting tasks.

| Tools required: | Materials required: |

|---|---|

| – Measuring tape

– Square – Drill – Drill bit – Screwdriver – Adjustable wrench |

– Base plate

– Guide rail – Fence – Screws |

Step-by-step Assembly of the Table Saw Fence Guide

Building a table saw fence guide is an essential step in improving the accuracy and efficiency of your woodworking projects. With a well-built fence guide, you can make precise cuts and ensure consistent results. In this step-by-step guide, we will walk you through the process of assembling a table saw fence guide.

Gather the Materials

Before starting the assembly, gather all the necessary materials and tools. You will need:

- A long aluminum extrusion

- A measuring tape

- A pencil

- A drill

- Screws

- A screwdriver

Measure and Mark

Measure and mark the desired length for your fence guide on the aluminum extrusion. Use a measuring tape and a pencil to make accurate marks.

Next, mark the positions for the screw holes. These holes will be used to attach the fence guide to the table saw. Make sure to space the holes evenly along the length of the extrusion.

Drill Holes

Using a drill, carefully drill holes at the marked positions. Start with a smaller drill bit and gradually increase the size to match the screws you will be using.

Attach the Fence Guide

Place the fence guide on the table saw, aligning the screw holes with the corresponding holes on the saw. Insert screws through the holes and tighten them using a screwdriver.

Make sure the fence guide is securely attached to the table saw and does not wobble or move during operation.

Test the Fence Guide

After attaching the fence guide, test it by making a few test cuts on scrap wood. Check the accuracy of the cuts and make any necessary adjustments to the fence guide.

Once you are satisfied with the performance of the fence guide, you are ready to start your woodworking projects with improved accuracy and confidence.

Remember to always wear protective gear, such as safety goggles and gloves, when using power tools and working with wood.

By following these step-by-step instructions, you can assemble a table saw fence guide and enhance the precision of your woodworking projects. Happy woodworking!