Creating strong and aesthetically pleasing dovetail joints is an essential skill for any woodworker. While there are various methods to achieve this classic woodworking joint, using a table saw can offer precise and efficient results. Whether you’re a beginner or an experienced woodworker, mastering the art of dovetail joints with a table saw can elevate your projects to new levels of craftsmanship.

To start, you’ll need a table saw equipped with a dado blade set. A dado blade set is specifically designed to cut grooves and splines, which are crucial in creating dovetail joints. Make sure to follow safety protocols and always wear protective gear, including safety glasses and gloves, when working with a table saw.

Begin by adjusting the table saw’s dado blade so that it makes cuts one-third the thickness of the wood you’re using. This ratio will ensure a strong and secure joint. Additionally, consider the size of your dovetails and adjust the blade accordingly. For smaller dovetails, a blade with a narrower width is more suitable, while wider dovetails require a wider blade.

With the dado blade properly set, you can now start making the cuts for your dovetail joints. Position the wood against the fence and adjust the height of the blade to match the desired depth of the grooves. Slowly feed the wood into the blade, keeping a steady and consistent pace. Repeat this process for each cut, ensuring they are evenly spaced and aligned.

Once you’ve made all the necessary cuts, it’s time to test the fit of your dovetail joints. Take a piece of scrap wood that matches the thickness of your main project and test-fit it into the grooves. The joint should be snug but not too tight. If the fit is too loose, adjust the blade height slightly and make another test cut. Remember, practice makes perfect, so don’t be discouraged if it takes a few tries to achieve the desired fit.

After perfecting the fit, you can proceed with creating dovetail joints on your actual project. Take your time and pay attention to detail, as precision is key in achieving sturdy and visually pleasing joints. Remember to double-check the alignment and spacing of each cut before proceeding.

In conclusion, making dovetail joints with a table saw can elevate your woodworking game to new heights. With the right tools, technique, and practice, you’ll be able to create elegant and durable joints that will enhance the quality and craftsmanship of your projects.

What are dovetail joints?

A dovetail joint is a strong and durable woodworking joint commonly used in carpentry and cabinetry. It is a interlocking joint that features a series of trapezoidal pins and tails that fit together tightly, forming a strong mechanical bond without the need for additional hardware or glue.

The shape of the pins and tails resembles the shape of a dove’s tail, hence the name “dovetail joint.” This intricate and precise joint requires a high level of skill and attention to detail to create, making it a true mark of craftsmanship.

Why are dovetail joints used?

Dovetail joints are used for several reasons:

- Strength: Dovetail joints provide exceptional strength and durability. The interlocking pins and tails resist pulling apart, making them ideal for structural connections in furniture and cabinetry.

- Aesthetics: Dovetail joints are visually appealing and considered a decorative element in woodworking. They showcase the skill and craftsmanship of the maker, adding a touch of elegance to the finished piece.

- Longevity: Dovetail joints are known for their longevity. The interlocking design distributes pressure evenly, reducing the risk of joint failure over time.

Types of dovetail joints

There are several types of dovetail joints, each with its own unique characteristics and applications:

- Through Dovetail Joint: This type of dovetail joint is commonly used in visible corners, such as in drawer construction. The pins and tails are visible from both sides of the joint, creating an attractive finish.

- Half-blind Dovetail Joint: This joint is often used in drawer fronts, where the pins are not visible from the front of the joint. It provides a clean and seamless appearance.

- Sliding Dovetail Joint: This joint is used when joining shelves or partitions to a panel, allowing for easy assembly and disassembly.

Overall, dovetail joints are a timeless and reliable choice in woodworking. They provide both strength and beauty, making them a preferred joint for many skilled craftsmen.

Benefits of using dovetail joints

The dovetail joint is a popular choice for woodworking projects due to its numerous benefits. Here are some key advantages of using dovetail joints:

- Strength and durability: Dovetail joints are known for their exceptional strength and durability. The interlocking design of the joint creates a tight bond that can withstand heavy loads and stress. This makes dovetail joints ideal for furniture and cabinetry that require long-lasting stability.

- Aesthetics: Dovetail joints are not only functional but also visually appealing. The unique, interlocking pattern of the joint adds a touch of craftsmanship and elegance to any woodworking project. The exposed dovetail joints can become a focal point, showcasing the skill and attention to detail of the craftsman.

- Pull-apart resistance: Unlike many other types of joints, dovetail joints are highly resistant to pull-apart forces. The shape of the joint prevents the pieces from separating easily, making it an excellent choice for drawer construction or any application that requires strength against lateral forces.

- Self-locking mechanism: Dovetail joints have a self-locking mechanism that helps hold the pieces together without the need for additional fasteners. This feature simplifies the assembly process and reduces the risk of the joint coming undone over time.

- Skill and craftsmanship: Creating dovetail joints requires a certain level of skill and precision. Mastering the art of dovetail joinery is considered a sign of a skilled woodworker. Using dovetail joints in your projects not only showcases your woodworking abilities but also reflects a commitment to quality and attention to detail.

In conclusion, dovetail joints offer numerous advantages in strength, durability, aesthetics, and functionality. Whether you are a hobbyist or a professional woodworker, mastering the art of dovetail joinery can significantly enhance the quality and beauty of your woodworking projects.

Tools and materials

Before you start making dovetail joints with a table saw, it is important to ensure that you have all the necessary tools and materials. Here is a list of what you will need:

| Table saw | A table saw is the main tool you will be using to make dovetail joints. Make sure it is in good working condition and has a sharp blade. |

| Dovetail jig | A dovetail jig is an essential tool that will help guide your cuts and ensure precise dovetail joints. Choose a jig that is suitable for your table saw and project. |

| Miter gauge | A miter gauge is used to guide the workpiece through the table saw. This tool is necessary for making accurate and consistent cuts. |

| Clamps | Clamps are required to secure your workpiece and jig in place during the cutting process. They help prevent movement and ensure clean and precise cuts. |

| Workpiece | You will need a piece of wood or another material to practice making dovetail joints. Choose a suitable size and type of wood for your project. |

| Safety gear | Ensure that you have the necessary safety gear, including safety glasses, ear protection, and a dust mask. These items will protect you from potential hazards and ensure a safe working environment. |

Having all the necessary tools and materials before you start will help ensure a smooth and successful dovetail joint-making process. Now that you have everything prepared, you can move on to the next steps.

Table Saw

A table saw is a versatile and powerful woodworking tool that is commonly used to make precise cuts and joinery, such as dovetail joints. It consists of a circular saw blade mounted on an arbor that is driven by an electric motor. The blade protrudes through the top surface of a flat table, providing a stable cutting surface.

Key Features of a Table Saw

Table saws come in various sizes and types, but they generally share some key features:

|

Rip Fence |

A rip fence is a guide that helps to keep the workpiece parallel to the blade during a rip cut, ensuring straight and accurate cuts. |

|

Miter Gauge |

A miter gauge is a device that can be angled and adjusted to guide the workpiece at various angles, allowing for precise crosscuts and angled cuts. |

|

Blade Height and Tilt Adjustments |

Most table saws have mechanisms for adjusting the blade height and tilt, which are essential for making various types of cuts, including dado cuts and bevel cuts. |

|

Dust Collection |

Many table saws come with dust collection systems or ports that can be connected to a vacuum or dust collector, helping to keep the work area cleaner and reducing the risk of airborne particles. |

Safety Considerations

When using a table saw, it is crucial to follow safety precautions to minimize the risk of accidents or injuries:

- Always wear safety goggles or glasses to protect your eyes from flying debris.

- Use a push stick or push block when feeding the workpiece through the blade, keeping your hands a safe distance away from the blade.

- Ensure that the blade guard and splitter are properly installed and functioning to prevent kickback.

- Keep the work area clean and free of clutter to avoid tripping hazards.

- Read and understand the manufacturer’s instructions and guidelines before operating the table saw.

By using a table saw safely and correctly, you can achieve precise and professional-looking results in your woodworking projects.

Dovetail Jig

A dovetail jig is a specialized woodworking tool used to create precise and strong dovetail joints. It is a useful accessory for a table saw, as it allows you to quickly and accurately produce dovetails in your projects.

Using a dovetail jig eliminates the need for hand-cutting dovetails, which can be time-consuming and require great skill and precision. With a dovetail jig, you can achieve professional-looking dovetail joints with ease.

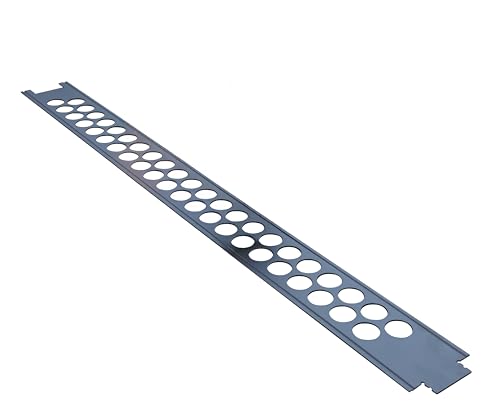

The jig consists of two main parts: a template and a guide. The template is made of durable material, such as aluminum or steel, and is designed to hold the workpiece securely in place. It has pre-cut slots that act as guides for the cutting tool.

The guide is used to hold the cutting tool, usually a router or a table saw with a dovetail bit. It ensures that the cuts are made at the correct angle and depth, resulting in perfectly fitting dovetails.

To use a dovetail jig, you first need to secure the template to the workpiece using clamps or screws. Then, you position the guide over the template and adjust it to the desired settings for your dovetail joints.

Once everything is set up, you can start making the cuts using the cutting tool. The guide will help you move the tool along the template, creating precise and clean dovetail joints.

One of the advantages of using a dovetail jig is its versatility. Most jigs allow you to create different types of dovetails, such as through dovetails, half-blind dovetails, and sliding dovetails. This gives you the flexibility to choose the type of joint that best suits your project.

In conclusion, a dovetail jig is a valuable tool for any woodworker who wants to create strong and attractive dovetail joints. It simplifies the process and ensures accuracy, making it a worthwhile investment for any woodworking enthusiast.

Clamps

Clamps are an essential tool when making dovetail joints with a table saw. They help to hold the workpieces securely in place, ensuring accurate and precise cuts.

There are several types of clamps that can be used for this task:

- C-Clamps: These clamps have a C-shaped frame and a screw mechanism that allows for easy adjustment and tightening. They are versatile and can be used to hold the workpiece in a variety of positions.

- Bar Clamps: These clamps consist of a long steel bar with a sliding jaw mechanism. They are ideal for clamping large workpieces, as they provide a wide and even distribution of pressure.

- Quick-Release Clamps: These clamps have a trigger mechanism that allows for quick and easy adjustment and release. They are ideal for repetitive tasks or when working with multiple workpieces.

- Spring Clamps: These clamps have a spring-loaded mechanism that provides a constant and even pressure. They are easy to use and are ideal for holding smaller workpieces.

When selecting clamps for making dovetail joints with a table saw, it is important to choose ones that are strong and durable. Look for clamps made of high-quality materials such as steel or cast iron, as they are less likely to bend or break under pressure.

Additionally, it is important to ensure that the clamps have enough clamping force to hold the workpiece securely in place. The clamps should be able to apply enough pressure to prevent any movement or shifting during the cutting process.

Using clamps when making dovetail joints with a table saw not only helps to ensure accurate and precise cuts but also improves safety by holding the workpiece securely in place. Investing in a variety of clamps will provide the necessary versatility for different types of cuts and workpiece sizes.

Measuring Tools

Accurate measurements are crucial when making dovetail joints with a table saw. To ensure precise and professional-looking results, it’s important to use the right measuring tools. Here are some essential measuring tools you will need:

Tape Measure

A tape measure is a must-have tool for any woodworking project. When making dovetail joints with a table saw, a tape measure helps you determine the length and width of the boards you’re working with. Make sure to choose a tape measure with a clear and easy-to-read markings for accurate measurements.

Combination Square

A combination square is another versatile tool that is essential for making dovetail joints. It consists of a ruler and a head that can be locked at different angles. You can use a combination square to mark the angles on the boards and ensure that they are cut accurately.

When using a combination square for dovetail joints, make sure to set it to the desired angle and firmly hold it against the edge of the board. Use a pencil or a knife to mark the lines along the edge, which will guide your saw cuts.

These are just a few of the measuring tools that can help you achieve accurate dovetail joints with a table saw. Remember to always double-check your measurements before making any cuts to ensure a precise fit and strong joint.

Preparing the wood

Before you can start making dovetail joints with a table saw, it’s important to properly prepare the wood you’ll be working with. This process ensures that your joints will be strong, neat, and fit together seamlessly.

1. Choose the right type of wood: Select a hardwood species such as oak or maple for its durability and strength. Softwood species like pine may not be as suitable for dovetail joints.

2. Mill the wood: Start by milling your wood to the desired thickness and width for the project. Use a jointer and planer to ensure flat and square sides.

3. Acclimate the wood: Allow the milled wood to acclimate in your workshop for several days. This helps the wood adjust to the humidity and temperature, reducing the risk of warping or cracking.

4. Mark the wood: Use a pencil or marking gauge to indicate the locations of your dovetail joints on the wood. This will help you make accurate cuts and ensure the joints fit together correctly.

5. Cut the wood to size: Use a miter saw or table saw to cut the wood into the desired lengths for your project. Always measure twice and cut once to avoid unnecessary waste.

6. Plane and sand the wood: Once you have cut the wood to size, use a hand plane or sandpaper to smooth out any rough edges or surfaces. This will ensure a clean and professional finish for your dovetail joints.

7. Arrange the wood: Lay out the pieces of wood in the desired orientation for your project. This will give you a clear idea of how the dovetail joints will come together and allow you to plan accordingly.

By following these steps and properly preparing your wood, you’ll be well on your way to creating strong and visually appealing dovetail joints with a table saw.