If you love working with wood, you know that making rip cuts is an essential skill. While a table saw is the go-to tool for this task, it’s not always available or practical to use. Luckily, there are alternative methods that can help you achieve clean and accurate rip cuts without a table saw. In this article, we will explore some of these options and provide step-by-step instructions to help you master the art of rip cutting.

1. Circular Saw Method: One of the most popular ways to make rip cuts without a table saw is by using a circular saw. This versatile tool can be adjusted to make precise cuts along the length of the wood. To ensure safety, always wear goggles and gloves when operating a circular saw. Start by marking your desired cut line on the wood using a straight edge. Then, set the depth of the circular saw blade slightly deeper than the thickness of the wood. Carefully align the saw blade with the cut line and slowly guide the saw along the wood, keeping a firm grip at all times. Remember to let the saw do the work and avoid forcing it through the wood.

2. Hand Saw Method: If you prefer a more traditional approach, you can also make rip cuts using a hand saw. While it may require more effort and precision, a hand saw can still deliver great results. Start by marking your cut line on the wood. Then, place the wood on a stable surface and use clamps to secure it in place. Grip the hand saw firmly and align the blade with the cut line. Apply light pressure and use long, smooth strokes to guide the saw through the wood. Take your time and let the saw’s teeth do the cutting. Remember to maintain a steady rhythm and avoid rushing the process.

3. Track Saw Method: Another option for making rip cuts without a table saw is by using a track saw. This tool is designed to run along a track, ensuring straight and accurate cuts. To get started, attach the track to your workpiece using clamps. Set the track saw to your desired width and tighten the blade. Align the saw’s guide with the edge of the track and start cutting by pushing the saw forward. Remember to apply even pressure and maintain a steady pace. The track will keep the saw aligned, allowing you to achieve clean and precise rip cuts.

By mastering these alternative methods, you can continue to enjoy the satisfaction of creating rip cuts even without a table saw. Whether you choose to use a circular saw, hand saw, or track saw, always prioritize safety and take the necessary precautions. With practice and patience, you’ll be able to make clean and accurate rip cuts on various woodworking projects.

Essential Tools for Rip Cuts

When it comes to making rip cuts without a table saw, there are a few essential tools that you will need to ensure clean and accurate cuts:

1. Circular Saw:

A circular saw is a versatile tool that can be used to make rip cuts in a wide range of materials. It is portable and easy to handle, making it a great alternative to a table saw. Make sure to choose a saw with a sharp blade that is suitable for the material you are cutting.

2. Straight Edge Guide:

To ensure straight and precise rip cuts, a straight edge guide is essential. This tool helps to guide the circular saw along the desired cutting line, ensuring accuracy and reducing the chances of any mistakes.

3. Clamps:

Clamps are necessary to secure the straight edge guide to the material being cut. This will keep the guide in place and prevent it from shifting during the cutting process, ensuring that your rip cuts are straight and consistent.

4. Measuring Tools:

Accurate measurements are crucial for making precise rip cuts. A tape measure and a carpenter’s square are essential tools that will help you take accurate measurements and mark the cutting lines properly.

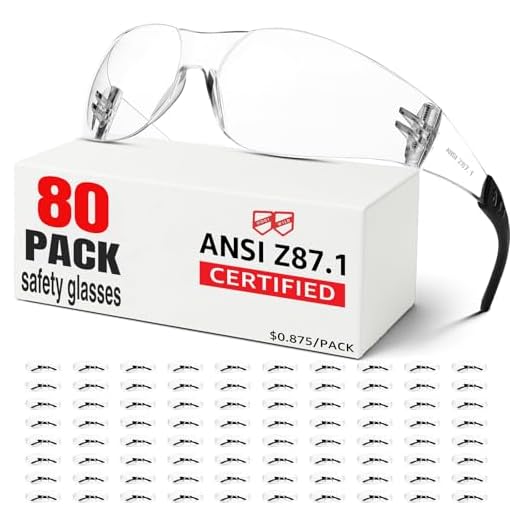

5. Safety Gear:

Ensuring your safety should always be a top priority when working with power tools. When making rip cuts, it is essential to wear safety goggles, ear protection, and gloves to protect yourself from any potential accidents.

By having these essential tools at hand, you can confidently make rip cuts without a table saw and achieve professional-looking results.

Setting Up a Circular Saw

To successfully make rip cuts without a table saw, you’ll need to properly set up your circular saw. Follow these steps to ensure a safe and accurate cut:

1. Choose the right blade: Select a carbide-tipped or rip-cutting blade. These blades are designed specifically for cutting wood along the grain and will provide clean and smooth cuts.

2. Adjust the depth: Before you begin cutting, adjust the depth of the saw blade. Set it so that the teeth protrude about 1/8 inch below the surface of the material you’re cutting. This will prevent the blade from binding and ensure a smooth cut.

3. Set the cutting angle: If you need to make an angled rip cut, adjust the bevel of the circular saw accordingly. Most circular saws have a bevel adjustment knob that allows you to set the desired angle. Use a protractor or angle guide to ensure accuracy.

4. Mark your cut line: Measure and mark the exact location of your rip cut on the material. Use a straight edge or a speed square to create a clear and straight line. This will serve as your guide throughout the cutting process.

5. Secure your material: To prevent the wood from moving during the cut, secure it firmly to a work surface using clamps or weights. This will ensure a clean and accurate cut without any unwanted movement.

6. Use a guide: For longer rip cuts, consider using a straight edge or a rip fence as a guide. Clamp the guide firmly in place along the cut line and run the circular saw against it. This will help you maintain a straight and consistent cut.

7. Practice safety precautions: Always wear safety goggles and hearing protection when operating a circular saw. Keep your hands away from the blade and be mindful of your body positioning. Familiarize yourself with the saw’s safety features and follow the manufacturer’s instructions.

With these steps in mind, you’ll be ready to make rip cuts with your circular saw safely and accurately, even without a table saw.

Choosing the Right Blade

When making rip cuts without a table saw, one of the most important factors to consider is choosing the right blade for the job. The type and quality of the blade you use can significantly affect the outcome of your cuts.

Types of Blades

There are several types of blades available for rip cutting, each designed for different materials and cutting applications. The two most common types are:

- Rip-cut blades: These blades feature fewer teeth with larger gaps between them. They are specifically designed for making fast and efficient rip cuts along the grain of the wood.

- General-purpose blades: These blades have a higher tooth count and are designed to handle a wider range of cutting tasks, including cross cuts and rip cuts. While they may not be as efficient as rip-cut blades for pure rip cutting, they offer versatility for various woodworking projects.

Factors to Consider

When choosing a blade for rip cutting, it’s important to consider the following factors:

- Tooth count: A lower tooth count typically indicates a blade designed for rip cuts. However, a blade with too few teeth may result in a rough cut. Aim for a balance between a lower tooth count for efficient ripping and enough teeth to ensure a clean finish.

- Tooth configuration: Blades with large gullets between the teeth help remove chips and prevent the blade from overheating during long rip cuts.

- Blade material: Choose a blade made from high-quality materials to ensure durability and longevity. Carbide-tipped blades are known for their sharpness and long cutting life.

- Blade width: The width of the blade determines how deep you can cut in a single pass. Choose a blade width suitable for the thickness of the material you’re cutting.

Ultimately, the right blade for your rip cuts will depend on the specific material and project at hand. It’s important to understand your cutting needs and choose a blade that aligns with those requirements.

Techniques for Accurate Rip Cuts

When it comes to making rip cuts without a table saw, there are several techniques you can use to ensure accuracy and precision. Whether you are using a circular saw or a handheld jigsaw, following these techniques will help you achieve straight and clean rip cuts.

1. Measure and Mark

Before making any cuts, it is essential to measure and mark the material accurately. Use a measuring tape or a ruler to determine the desired width of the rip cut. Then, mark the measurement on both ends of the material with a pencil or a marking tool.

2. Use a Guide

Using a guide is crucial for maintaining a straight line while cutting. You can use a straight piece of lumber or a metal straight edge as a guide. Clamp the guide securely to the material, aligning it with the marked line. This will help you keep the saw blade on track, resulting in a precise rip cut.

Alternatively, you can also make your own guide by attaching a piece of scrap wood to the base of your handheld saw. This will provide a reliable reference for the saw to follow along the marked line.

3. Take Multiple Passes

When making rip cuts with a circular saw or a jigsaw, it is often best to take multiple passes instead of trying to cut through the material in one go. This will not only reduce the strain on the saw but also allow for better control and accuracy.

Start by making a shallow initial cut along the marked line. Then, gradually increase the depth of the cut with each pass until you reach the desired depth. This method will prevent the blade from binding and ensure cleaner and more precise rip cuts.

| Pros | Cons |

|---|---|

| Allows for accurate and precise rip cuts | Requires extra time and patience |

| Reduces the strain on the saw | May require multiple adjustments of the guide |

| Produces clean and straight cuts | May lead to tear-out on certain materials |

By following these techniques, you can confidently make rip cuts without a table saw. Remember to prioritize safety, wear appropriate protective gear, and always handle power tools with caution.

Safety Precautions:

When making rip cuts without a table saw, it is important to prioritize safety. Follow these precautions to ensure a safe working environment:

- Wear appropriate safety gear, including safety glasses, ear protection, and gloves.

- Make sure the work area is well-lit and free of any potential hazards.

- Always use sharp and properly maintained tools to minimize the risk of accidents.

- Secure the material you are cutting with clamps or other appropriate means to prevent it from moving during the cut.

- Use a straight edge or guide to ensure accurate and straight cuts.

- Keep your hands and fingers clear of the cutting path at all times.

- Take your time and maintain a steady pace to avoid rushing and making mistakes.

- Do not force the saw or apply excessive pressure on the material. Let the tool do the work.

- Keep children and pets away from the work area to avoid any potential accidents.

- If you are unfamiliar with the tools or cutting techniques, seek guidance from an experienced individual or a professional.

By following these safety precautions, you can minimize the risk of accidents and injuries while making rip cuts without a table saw.