If you enjoy working with wood and have a table saw in your workshop, you may have encountered the challenge of square cuts on plywood sheets. Plywood tends to have uneven edges, making it difficult to get precise and square cuts. However, with the right technique and some careful adjustments, you can easily square up plywood on a table saw.

Step 1: Measure and Mark

Before starting, carefully measure and mark the dimensions you need on the plywood sheet. Use a straightedge or a framing square to ensure accurate measurements and make clear, visible marks on the surface of the plywood.

Step 2: Adjust the Blade Height

To achieve clean and square cuts, it’s essential to have the correct blade height. Adjust the blade height so that it is slightly higher than the thickness of the plywood. This will prevent any tear-out or splintering on the plywood surface during cutting.

Step 3: Set Up the Fence

Setting up the fence is crucial to ensure accurate and square cuts. Make sure the fence is parallel to the blade and positioned at the desired width. Use a tape measure or a ruler to double-check the distance between the blade and the fence, ensuring it matches your intended cut width.

Step 4: Make the Cuts

With the blade height and fence properly adjusted, it’s time to make the cuts. Feed the plywood sheet slowly and steadily through the blade, keeping it firmly against both the fence and the table. Use a push stick or push block to maintain a safe distance between your hands and the blade.

Step 5: Check for Accuracy

Once you’ve made the cuts, take a moment to assess the accuracy of your square cuts. Use a measuring tape or a square to check if the corners are 90 degrees and if the dimensions match your initial marks. If necessary, make any adjustments to the table saw settings and repeat the process until you achieve the desired results.

Remember, working with power tools requires caution and safety measures. Always wear appropriate protective gear, such as safety goggles and hearing protection. Follow the manufacturer’s instructions and guidelines for your specific table saw model. With practice and attention to detail, you’ll be able to square up plywood on a table saw with confidence and precision.

Steps to Square up Plywood on Table Saw

Squaring up plywood on a table saw is an essential skill for any woodworker. The process ensures that the edges of the plywood are at a perfect 90-degree angle to each other, resulting in a precise and professional-looking cut. Here are the steps to square up plywood on a table saw:

| Step 1: | Set up your table saw with a square blade and adjust the fence to the desired width of the cut. |

| Step 2: | Place the plywood on the table saw, making sure that one edge is flush against the fence and the other edge is on the opposite side of the blade. |

| Step 3: | Carefully push the plywood through the blade, maintaining a steady and even pressure. Be sure to use a push stick or push block to keep your hands safe and away from the blade. |

| Step 4: | Once the first cut is complete, rotate the plywood 180 degrees so that the cut edge is now against the fence. |

| Step 5: | Make a second cut, again using a push stick or push block to guide the plywood through the blade. |

| Step 6: | After both cuts are complete, check the corner for squareness using a square. If the corner is not perfectly square, make minor adjustments to the fence and repeat the process until the desired result is achieved. |

Squaring up plywood on a table saw may take some practice, but with time and patience, you can master this essential woodworking technique. Remember to always prioritize safety by using proper protective gear, following tool instructions, and keeping your hands away from the blade.

Prepare the Plywood

Before you can square up plywood on a table saw, you need to properly prepare the plywood and ensure it is clean and free from any debris or dirt. Follow these steps to prepare the plywood:

Step 1: Measure and Mark

Start by measuring the dimensions of the plywood piece you want to square up. Use a measuring tape to measure both the length and the width, and then mark the desired dimensions on the plywood using a pencil or a marking tool. This will guide you when cutting the plywood on the table saw.

Step 2: Inspect the Plywood

Inspect the plywood for any imperfections such as knots, cracks, or splintered edges. If you find any, mark them with a pencil or a piece of tape so you can avoid them when making your cuts. It’s important to work with high-quality plywood to achieve accurate and precise cuts.

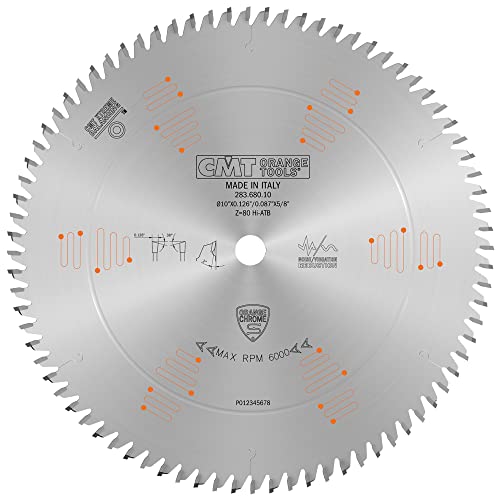

Step 3: Set up the Table Saw

Make sure the table saw is properly set up before starting the cutting process. Ensure that the fences are aligned square to the blade and that the blade is set at the desired height for your cuts. Additionally, ensure that the blade is sharp and in good condition to prevent splintering or tear-out.

Note: It is always recommended to wear appropriate safety gear, such as safety goggles and ear protection, when operating a table saw.

By carefully preparing the plywood and ensuring that the table saw is set up properly, you can proceed with the process of squaring up the plywood on the table saw.

Set up the Table Saw

Before you begin squaring up plywood on a table saw, it’s important to properly set up the table saw to ensure accurate cuts and a safe working environment. Follow these steps to get your table saw ready:

1. Check the Alignment

Start by checking the alignment of the blade and the fence. Make sure the blade is perpendicular to the table surface and that the fence is parallel to the blade. Use a combination square or a specialized alignment tool to ensure accuracy.

2. Adjust the Height

Next, adjust the height of the blade to the appropriate level for cutting plywood. The height should be set just above the thickness of the plywood to reduce tear-out and ensure clean cuts.

Note: Be sure to consult your table saw’s manual for specific instructions on adjusting the blade height.

3. Install the Riving Knife

Always use a riving knife when cutting plywood or any other material on the table saw. A riving knife helps prevent kickback and keeps the wood from pinching the blade, ensuring a smooth and safe cutting experience. Install the riving knife according to the manufacturer’s instructions.

4. Check the Safety Features

Before using the table saw, verify that all safety features are in place and functioning correctly. This includes the blade guard, anti-kickback pawls, and the emergency stop switch. These features are designed to protect you from accidents and should be used at all times.

Remember: Safety should always be your top priority when operating a table saw, so take the time to familiarize yourself with the safety features and use them accordingly.

Once the table saw is properly set up and the safety features are in place, you can proceed to square up your plywood with confidence!

Measure and Mark

Before starting the process of squaring up plywood on a table saw, it is important to measure and mark the areas that need to be cut. This will help ensure accuracy and a proper fit.

To measure the plywood, use a tape measure to determine the dimensions needed for your project. Measure both the length and width, making note of any additional cuts or angles that may be required.

Once the measurements are determined, use a straightedge or square to mark the plywood with a pencil or marking knife. This will create a clear guideline for cutting.

Measuring Tips

When measuring, it is essential to be precise. Ensure that the tape measure is straight and not twisted to avoid any inaccuracies in the measurements.

If you need to make multiple cuts, consider labeling each piece with corresponding measurements to prevent confusion later on.

Note: Always double-check your measurements before making any cuts to avoid wastage of plywood.

Take your time with the measuring and marking process to ensure the best results.

Position the Plywood

Before making any cuts, it’s important to position the plywood properly on the table saw. This will help ensure accurate and square cuts.

1. Clear the Workspace

Start by clearing the table saw and the surrounding area of any debris or tools that may obstruct your work or cause safety hazards.

2. Adjust the Fence

Next, adjust the fence of the table saw to the desired width of the cut. The fence should be parallel to the blade and securely locked in place.

3. Place the Plywood

Carefully place the plywood sheet on the table saw, ensuring that the edge to be cut is lined up with the fence. The sheet should lay flat on the table with no overhang or uneven areas.

4. Support the Plywood

If working with larger and heavier plywood sheets, it’s advisable to use auxiliary support such as sawhorses or roller stands. These supports will help maintain stability and prevent sagging during the cutting process.

5. Double-Check Alignment

Before making any cuts, double-check the alignment of the plywood sheet. Ensure that it is flush against the fence and evenly supported across its length. This will help maintain accuracy and prevent any mishaps during the cutting process.

Remember to always prioritize safety when working with power tools. Wear appropriate safety gear and follow the manufacturer’s instructions for your specific table saw model.

Cut the Plywood

Now that you have positioned the plywood on the table saw and adjusted the blade height, it’s time to make the cut. Before proceeding, make sure you are wearing the appropriate safety gear, including safety glasses and hearing protection.

Start by aligning one edge of the plywood with the rip fence. This will ensure a straight and accurate cut. Use a push stick to guide the plywood through the blade, keeping your hands a safe distance away from the blade. Apply steady pressure as you push the plywood through, making sure to maintain even contact with the rip fence.

Once the first cut is complete, turn off the table saw and inspect the cut edge. If necessary, use a straight edge or square to check for any irregularities. If the cut edge is not perfectly straight, adjust the rip fence and recut the plywood, ensuring proper alignment with the fence before making the cut.

Repeat the process

Continue making cuts along the remaining edges of the plywood until you have squared up all sides. Remember to always use a push stick and exercise caution while operating the table saw. Double-check each cut for accuracy to ensure the final piece is square.

Clean up

Once you have finished cutting the plywood, carefully remove it from the table saw. Clean up any sawdust or debris from the work area to maintain a safe workspace. Store the leftover pieces of plywood properly and safely dispose of any waste materials.