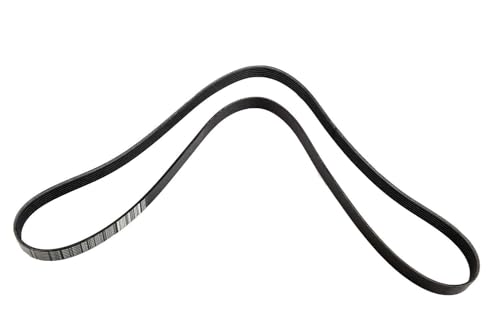

A wedge belt, also known as a V-belt or a Vee belt, is a type of power transmission belt used in various applications, such as industrial machinery, automotive engines, and agricultural equipment. It is called a “wedge belt” because of its shape – it has a trapezoidal cross-section that forms a wedge when wrapped around pulleys.

The wedge belt is made of a flexible material, such as rubber or synthetic compounds, which allows it to bend and conform to the shape of the pulleys. This flexibility enables the belt to transmit power from the driving pulley to the driven pulley by creating friction and grip between the belt and the pulleys.

One of the key advantages of the wedge belt is its ability to transmit high levels of power efficiently. The design of the belt allows for a large surface area of contact with the pulleys, which improves the transfer of torque and minimizes slippage. Additionally, the trapezoidal shape of the belt helps to increase the grip and prevent the belt from slipping off the pulleys, even under heavy loads or high-speed rotations.

Wedge belts are commonly used in a wide range of applications, including power transmission systems, HVAC systems, conveyor systems, and pumps. They are known for their reliability, durability, and ease of installation. The maintenance of a wedge belt is relatively simple and involves periodic inspections for wear and proper tensioning to ensure optimal performance.

Understanding the Functionality of a Wedge Belt

A wedge belt, also known as a V-belt or a Vee belt, is a type of power transmission belt that is commonly used in industrial machinery. It features a trapezoidal cross-section and is made of a rubber or synthetic material that is reinforced with a fabric or steel cord for added strength and durability. The unique design of the wedge belt allows it to transmit power efficiently and reliably between two rotating pulleys.

How Does a Wedge Belt Work?

The wedge shape of the belt creates a larger contact surface with the pulleys compared to a flat belt, which increases the friction between the belt and the pulley. This increased friction allows the belt to grip the pulleys tightly, preventing slippage and ensuring the smooth transfer of power. The trapezoidal shape of the belt also helps distribute the load evenly across its width, reducing stress and prolonging the lifespan of the belt.

Advantages of Using a Wedge Belt

- Higher Power Transmission: The wedge shape and increased friction of the belt allow it to transmit higher levels of power compared to a flat belt. This makes it suitable for demanding applications that require more torque.

- Reduced Slippage: The tight grip of the belt on the pulleys minimizes slippage, ensuring efficient power transfer and preventing damage to the machinery.

- Space-saving Design: Wedge belts are narrower compared to other types of power transmission belts, allowing for more compact machine designs and efficient use of space.

- Low Maintenance: Due to their durable construction, wedge belts have a longer lifespan and require less frequent maintenance compared to other types of belts.

Overall, understanding the functionality of a wedge belt is essential for ensuring the efficient and reliable operation of industrial machinery. By utilizing the unique features of a wedge belt, such as its trapezoidal shape and increased friction, industries can achieve higher power transmission, lower slippage, space-saving designs, and reduced maintenance requirements.

Advantages and Benefits of Using a Wedge Belt

A wedge belt, also known as a V-belt, is a type of power transmission belt that has a trapezoidal cross-section. It is primarily used to transfer power in industrial applications, such as in machinery and automotive engines. Here are some advantages and benefits of using a wedge belt:

1. High power transmission efficiency:

One of the main advantages of a wedge belt is its high power transmission efficiency. The unique design of the belt allows it to effectively transmit power between the driver and driven components, minimizing energy losses due to slippage or friction. This high efficiency helps improve the overall performance of the system.

2. Compact design:

Wedge belts have a compact design that allows them to be used in tight spaces. The trapezoidal shape of the belt allows for a smaller bend radius, making it easier to fit in confined areas. This flexibility in design makes wedge belts suitable for a wide range of applications.

3. Reduced vibration and noise:

Wedge belts are known for their ability to reduce vibration and noise levels during operation. The unique shape of the belt helps dampen vibrations, resulting in smoother and quieter operation compared to other belt types. This makes wedge belts ideal for applications where noise reduction is critical.

4. Easy installation and maintenance:

Installing and maintaining a wedge belt is relatively easy compared to other belt types. The trapezoidal shape allows for easy alignment and tensioning, reducing the time and effort required for installation. Additionally, wedge belts have a longer lifespan and require less frequent maintenance, resulting in cost savings over time.

5. Wide range of application:

Wedge belts are versatile and can be used in a wide range of applications. From industrial machinery to automotive engines, they are capable of transferring power reliably and efficiently. This versatility makes them a popular choice in various industries.

In conclusion, wedge belts offer numerous advantages and benefits, including high power transmission efficiency, compact design, reduced vibration and noise levels, easy installation and maintenance, and a wide range of applications. These advantages make wedge belts a preferred choice for power transmission in various industrial and automotive applications.

Important Factors to Consider When Choosing a Wedge Belt

When choosing a wedge belt, there are several important factors that you should consider to ensure optimal performance and longevity:

1. Belt Material: The material used for the wedge belt is crucial in determining its durability and resistance to wear. Common materials used for wedge belts include rubber and polyurethane. Rubber belts are known for their flexibility and resistance to heat, while polyurethane belts offer higher resistance to abrasion and stretching.

2. Belt Width: The width of the belt plays a significant role in power transmission efficiency. A wider belt allows for a larger contact area with the pulley, resulting in improved grip and reduced slippage. However, wider belts may require larger pulleys and may not be suitable for all applications.

3. Belt Length: The length of the belt should be carefully selected to ensure proper tensioning and alignment. A belt that is too short may not provide adequate tension, leading to slippage, while a belt that is too long may cause excessive stretching and premature failure.

4. Belt Profile: The profile of the belt determines its compatibility with the pulley groove. Common belt profiles include A, B, C, and D, with each profile designed for specific load and horsepower requirements. It is important to choose a belt profile that matches the pulley groove to ensure optimal performance.

5. Load and Power Requirements: The load and power requirements of the application should be taken into consideration when choosing a wedge belt. It is essential to select a belt that can handle the required load and horsepower without exceeding its maximum capacity. Failure to do so may result in belt failure or reduced performance.

6. Environment Conditions: The operating environment conditions, such as temperature, humidity, and exposure to chemicals or oils, should be evaluated when selecting a wedge belt. Certain materials may be better suited for specific environmental conditions to ensure proper functioning and longevity of the belt.

7. Manufacturer Reputation: Lastly, it is important to choose a wedge belt from a reputable manufacturer that has a proven track record of producing high-quality belts. A trusted manufacturer will ensure consistent product quality and provide technical support if needed.

By considering these important factors when choosing a wedge belt, you can ensure that you select the right belt for your application, maximizing efficiency and minimizing downtime.

Common Applications and Industries that Utilize Wedge Belts

Wedge belts, also known as V-belts, are used in a wide range of applications across various industries. The unique design and construction of wedge belts make them suitable for high-power transmission and efficient operation.

Some of the common applications of wedge belts include:

- Industrial machinery and equipment: Wedge belts are extensively used in industrial machinery such as pumps, compressors, generators, and conveyors. They provide reliable and efficient power transmission, ensuring smooth operation of the equipment.

- Agricultural machinery: Wedge belts are widely used in agricultural machinery, including tractors, harvesters, and balers. These belts help transfer power from the engine to various components, such as the tiller, cutting blades, or the harvesting mechanism.

- Automotive industry: Wedge belts are used in vehicles for various applications, including power steering, air conditioning compressors, and water pumps. They provide a compact and reliable solution for transmitting power to these components.

- Construction equipment: Wedge belts are commonly used in construction equipment, such as concrete mixers, pumps, and cranes. They ensure efficient power transmission and help maintain the reliability of these machines even in demanding working conditions.

- Power transmission: Wedge belts are a popular choice for power transmission in a wide range of industries, including mining, oil and gas, and manufacturing. Their robust construction and high-power capacity make them suitable for handling heavy loads and continuous operation.

In conclusion, wedge belts find applications in various industries and play a crucial role in ensuring efficient power transmission and smooth operation of machinery and equipment. Their versatility and reliability make them a preferred choice for many different applications.

Maintaining and Extending the Lifespan of a Wedge Belt

A wedge belt is an important component in many industrial applications, providing power transmission and reliability. To ensure optimal performance and longevity, it’s essential to properly maintain and take steps to extend the lifespan of a wedge belt. Here are some key tips to consider:

- Regular Inspection: Regularly inspect the wedge belt for any signs of wear, such as cracks, fraying, or uneven surfaces. This can help identify issues early on and prevent sudden failures.

- Tension Adjustment: Proper tension is crucial for optimal belt performance. Over-tensioning can cause excessive wear, while under-tensioning can result in slipping and reduced efficiency. Follow the manufacturer’s guidelines for proper tension adjustment.

- Clean and Lubricate: Keep the wedge belt clean and free from debris to prevent damage. Additionally, lubricate the pulleys and ensure they are properly aligned to minimize friction and wear.

- Temperature Control: Excessive heat can negatively impact the lifespan of a wedge belt. Ensure that the operating temperature doesn’t exceed the recommended limits and take necessary steps to control heat generation, such as proper ventilation or insulation.

- Storage: When storing spare wedge belts, keep them in a cool, dry place away from direct sunlight and extreme temperatures. Avoid placing heavy objects on top of them to prevent deformation.

- Proper Handling: When installing or replacing a wedge belt, handle it with care to avoid bending or twisting. Improper handling can lead to premature wear and failure.

- Regular Maintenance: Implement a regular maintenance schedule to inspect and perform necessary adjustments or replacements as needed. This can help catch potential issues early and ensure optimal belt performance.

By following these maintenance tips, you can help maintain the performance and extend the lifespan of a wedge belt, ultimately reducing downtime and increasing overall productivity in industrial applications.