Are you tired of struggling to remove dried caulk from your Milwaukee caulking gun? Well, we have good news for you! In this article, we will guide you step by step on how to easily reverse your Milwaukee caulking gun, making your caulking job a breeze.

Reversing a Milwaukee caulking gun is a simple process that can save you a lot of frustration and time. By reversing the gun, you can easily remove any dried caulk that may be clogging the nozzle, ensuring a smooth and uninterrupted flow of fresh caulk.

To reverse your Milwaukee caulking gun, follow these easy steps:

- Remove the caulk tube: Start by removing the caulk tube from the gun. This can be done by pushing the release button located at the back of the gun and pulling the tube out.

- Release the plunger rod: Next, release the plunger rod by pulling back on the rod handle. This will allow you to access the reverse lever.

- Engage the reverse lever: Locate the reverse lever on the side of the gun and engage it by pushing it towards the front of the gun. This will unlock the plunger rod and allow it to reverse.

- Reverse the plunger rod: With the reverse lever engaged, push the plunger rod towards the back of the gun. This will reverse the plunger rod, pushing any dried caulk out of the nozzle.

- Clear the nozzle: Once the plunger rod is fully reversed, use a clean cloth or paper towel to wipe away any excess caulk that may have been pushed out of the nozzle.

That’s it! You have successfully reversed your Milwaukee caulking gun. Now you can reassemble the gun by inserting a new caulk tube and you’re ready to go. Remember to always clean your caulking gun after each use to ensure its longevity and proper functionality.

Disclaimer: Before attempting to reverse your Milwaukee caulking gun, always refer to the manufacturer’s instructions or consult a professional if you are unsure. Safety should be your top priority.

What is a Milwaukee Caulking Gun

A Milwaukee caulking gun is a tool used for applying caulk or sealant. It is specifically designed to assist in sealing joints and filling gaps. The gun is typically sturdy and durable, making it suitable for both DIY projects and professional use.

Features and Benefits

One of the main features of a Milwaukee caulking gun is its ergonomic design. The gun is designed to be comfortable to hold and easy to use, reducing fatigue during extended periods of caulking. It often comes with a non-slip grip, allowing for better control and precision.

Another significant feature is the gun’s adjustable caulk flow rate. This allows for easy control of the amount of caulk being dispensed, preventing excessive or insufficient application. Some models also have a built-in dripless mechanism, minimizing the mess caused by excess caulk.

A Milwaukee caulking gun also often features a quick-release lever, which allows for easy and convenient loading and unloading of caulk tubes. This makes the tool efficient and time-saving, as it eliminates the need for manual caulking gun adjustments.

Types of Milwaukee Caulking Guns

There are various types of Milwaukee caulking guns available on the market, each suited for different applications. These include:

- Manual caulking guns: These are the basic, hand-operated caulking guns. They require manual force to dispense the caulk.

- Battery-powered caulking guns: These guns are powered by a rechargeable battery, reducing the effort required to dispense caulk. They are ideal for heavy-duty applications and lengthy projects.

- Pneumatic caulking guns: These guns are powered by an air compressor. They offer a high level of control and precision, making them suitable for professional use.

Overall, a Milwaukee caulking gun is a versatile tool that can make any caulking job easier and more efficient. With its durable construction and various features, it is a reliable choice for both DIYers and professionals in need of a dependable caulking tool.

Importance of Reversing the Milwaukee Caulking Gun

Reversing the Milwaukee caulking gun is an essential process that every user should be familiar with. Whether you are a professional contractor or a DIY enthusiast, understanding the importance of reversing the caulking gun will help you achieve better results and make the caulking process more efficient.

Preventing Waste

One of the main reasons why it is important to reverse the Milwaukee caulking gun is to prevent waste. When you apply caulk to a surface, there is often leftover material in the gun’s barrel. This unused caulk can quickly dry out and become unusable, resulting in wasted money and resources.

By reversing the caulking gun, you can effectively remove any excess caulk from the barrel. This process ensures that you use every last bit of caulk and reduces waste, saving you money in the long run.

Ensuring Proper Functionality

Reversing the Milwaukee caulking gun is also crucial for ensuring its proper functionality. Over time, caulk can build up inside the barrel and the nozzle, causing clogs and hindering the gun’s performance. If the caulk is not cleared regularly, it can lead to uneven application and a messy caulking job.

By reversing the caulking gun, you can easily clear out any accumulated caulk and debris. This helps to maintain the gun’s functionality, allowing for smooth and consistent application of caulk. It also extends the lifespan of the tool, reducing the need for frequent repairs or replacements.

Promoting Professional Results

When it comes to caulking, achieving professional-looking results is a top priority. Whether you are sealing gaps around windows or applying caulk to a tub, you want the finished product to appear neat and seamless.

Reversing the Milwaukee caulking gun is a crucial step in achieving professional results. It helps to remove any excess caulk that may have seeped out during the application process. This prevents unsightly smudges and drips and ensures a clean finish.

Additionally, reversing the caulking gun allows for better control and precision. It helps to achieve a steady flow of caulk, making it easier to fill gaps and create clean lines. The result is a professional-looking caulking job that adds value and aesthetic appeal to your project.

- Prevents waste by ensuring efficient use of caulk

- Maintains the caulking gun’s functionality by removing accumulated caulk and debris

- Helps to achieve professional-looking results by promoting better control and precision

Overall, the importance of reversing the Milwaukee caulking gun cannot be overstated. By doing so, you can prevent waste, maintain functionality, and achieve professional results in your caulking projects. So, make sure to incorporate this crucial step into your caulking routine for a successful and satisfying outcome.

Step 1: Prepare the Caulking Gun

Before you can reverse the Milwaukee caulking gun, you need to prepare the tool for the process. This involves ensuring that the gun is clean and free of any old caulk or debris.

Here are the steps to properly prepare the caulking gun:

| Step | Description |

| 1 | Remove any remaining caulk |

| 2 | Detach the cartridge holder |

| 3 | Inspect the gun for any blockages |

| 4 | Clean the gun with warm soapy water |

| 5 | Dry the gun thoroughly |

By completing these steps, you will ensure that your Milwaukee caulking gun is ready for the reversal process. Cleaning the gun and removing any old caulk or debris will prevent any issues or malfunctions during the reversal process.

Gather the Necessary Tools and Materials

Before you can begin reversing your Milwaukee caulking gun, it’s important to gather all the necessary tools and materials. Having everything prepared beforehand will make the process smoother and more efficient.

Tools

Here are the tools you will need:

- Phillips head screwdriver

- Flathead screwdriver

- Needle nose pliers

- Adjustable wrench

Materials

In addition to the tools, you will also need the following materials:

- New caulk tube

- Replacement plunger rod (if necessary)

- Grease or lubricant

Make sure that you have all these tools and materials readily available before you start the reverse process. This way, you won’t have to interrupt your progress and search for items or rush to the store in the middle of the task.

Clean the Caulking Gun

To ensure the proper functioning and longevity of your Milwaukee caulking gun, it is essential to regularly clean it after each use. This will help prevent the buildup of dried caulk residue and keep the gun in optimal condition for future projects.

Follow these steps to clean your Milwaukee caulking gun:

- Disconnect the cartridge or tube: Before cleaning the caulking gun, you need to remove the cartridge or tube from the gun. To do this, release the pressure by pushing the release lever or button, then carefully detach the cartridge or tube from the gun.

- Remove excess caulk: Use a putty knife or a clean rag to remove any excess caulk from the gun. Be sure to remove caulk from the barrel, plunger, and nozzle to ensure a thorough cleaning.

- Prepare a cleaning solution: Fill a small container with warm soapy water or a mild cleaning solution. You can also use a commercial caulk remover if needed. Make sure the container is big enough to accommodate the removable parts of the caulking gun.

- Disassemble the caulking gun: Break down the caulking gun into its individual components. This typically includes removing the plunger, nozzle, and any other detachable parts. Refer to the manufacturer’s instructions if you are unsure how to disassemble your particular caulking gun model.

- Soak the parts: Place the disassembled parts into the container with the cleaning solution. Allow them to soak for at least 15-30 minutes to loosen any stubborn caulk residue.

- Clean the parts: After soaking, use a soft brush or toothbrush to scrub away any remaining caulk residue from the parts. Pay special attention to the nozzle and plunger, as these areas tend to collect the most caulk buildup.

- Rinse and dry: Thoroughly rinse all the parts with clean water to remove any traces of the cleaning solution. Dry the parts with a clean towel or allow them to air dry.

- Reassemble the caulking gun: Once all the parts are completely dry, reassemble the caulking gun by attaching the plunger, nozzle, and other components back onto the gun. Ensure that everything is properly aligned and secured.

- Store the caulking gun: Finally, store your clean Milwaukee caulking gun in a dry and secure location until its next use. This will help prevent any further contamination or damage.

By following these steps and regularly cleaning your Milwaukee caulking gun, you can extend its lifespan and ensure optimal performance for future projects.

Step 2: Remove the Existing Caulk

Before you can use a Milwaukee caulking gun to apply new caulk, you will need to remove any existing caulk from the area. Here’s how to do it:

- Prepare the area: Before you start removing the caulk, make sure the surface is clean and dry. Use a damp cloth or sponge to wipe away any dirt or debris.

- Score the caulk: With a utility knife or caulk scraper, carefully score the caulk along the edges where it meets the surface. This will help loosen the caulk and make it easier to remove.

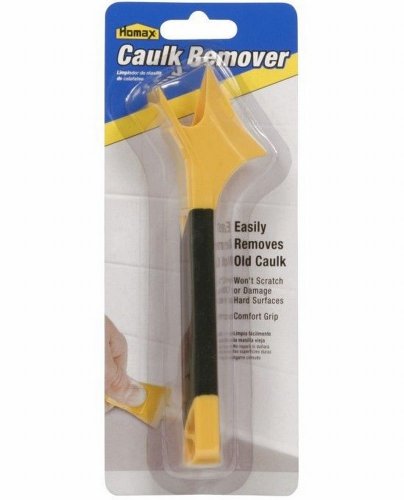

- Remove the caulk: Using a caulk removal tool or your utility knife, gently pry up one end of the caulk strip. Slowly pull it away from the surface, applying steady and even pressure. If the caulk doesn’t come off easily, you may need to score it again or use more force.

- Clean the area: Once the caulk is removed, use a caulk remover or adhesive remover to clean any leftover residue. Follow the instructions on the product for best results.

- Dry the area: After cleaning, make sure the surface is completely dry before applying new caulk. Use a clean cloth or allow the area to air dry.

By properly removing the existing caulk, you ensure that the new caulk will adhere to the surface effectively, providing a tight seal and a professional finish.

Select the Appropriate Removal Method

When it comes to reversing a Milwaukee caulking gun, it’s important to select the appropriate removal method based on the type of caulk or sealant used. Here are a few options to consider:

1. Mechanical Method: This method involves manually removing the caulk or sealant using a scraper or a putty knife. Start by scoring the caulk or sealant with the scraper or knife and then slowly peel it away from the surface. Be careful not to damage the surface while removing the caulk.

2. Chemical Method: Some caulk or sealant may require the use of chemicals to effectively remove it. There are various caulk removers available in the market that can be used for this purpose. Follow the instructions provided on the caulk remover product and apply it to the caulk or sealant. Allow the remover to sit for a while, typically a few minutes, and then use a scraper or putty knife to remove the softened caulk.

3. Heat Method: Heat can also be used to soften the caulk or sealant, making it easier to remove. You can use a heat gun or a hairdryer on the low heat setting to warm the caulk. Be cautious not to overheat the caulk as it can damage the surrounding surface. Once the caulk is softened, use a scraper or putty knife to remove it gently.

Remember to wear protective gear, such as gloves and safety goggles, while removing the caulk or sealant. Always follow the safety instructions provided by the manufacturer of the caulking gun and the removal method you choose. This will ensure a safe and effective caulk removal process.

Work Carefully to Avoid Damaging the Surface

When you are using a Milwaukee caulking gun to reverse the caulk application, it is essential to work carefully to avoid damaging the surface.

First, ensure that the surface you are working on is clean and free from any dirt, debris, or old caulk. Use a scraper or a putty knife to remove any loose or old caulk before starting the reverse process.

Next, insert the caulk remover tool into the cartridge and carefully pull back to start reversing the caulk. It is important to use slow, steady pressure to avoid any sudden movements that could damage the surface.

While reversing the caulk, keep a close eye on the surface to ensure that it is not getting scratched or damaged. If you notice any signs of damage, stop immediately and reassess your technique or consider seeking professional help.

Additionally, be mindful of any surrounding surfaces, such as tiles or countertops, that may be sensitive to scratches or marks. Use a protective layer, such as a piece of cardboard or a piece of cloth, to create a barrier between the caulking gun and these surfaces.

Finally, after you have successfully reversed the caulk, clean the surface using a mild soap and water solution to remove any residue. Thoroughly dry the area before applying any new caulk or sealant.

Remember: Working carefully and taking your time during the caulk reversal process will help prevent any damage to the surface and ensure a successful outcome for your project.